Alkyl capped oil soluble polymer viscosity index improving additives for base oils in industrial lubricant applications

An industrial lubricant, an industrial-based technology, applied in the field of base oil formulations, can solve problems such as increasing the viscosity of lubricants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

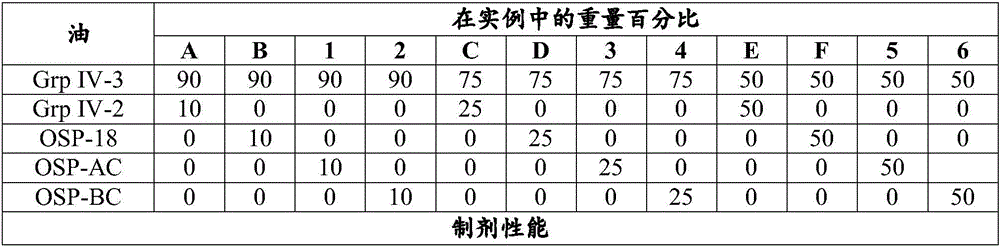

Examples

example

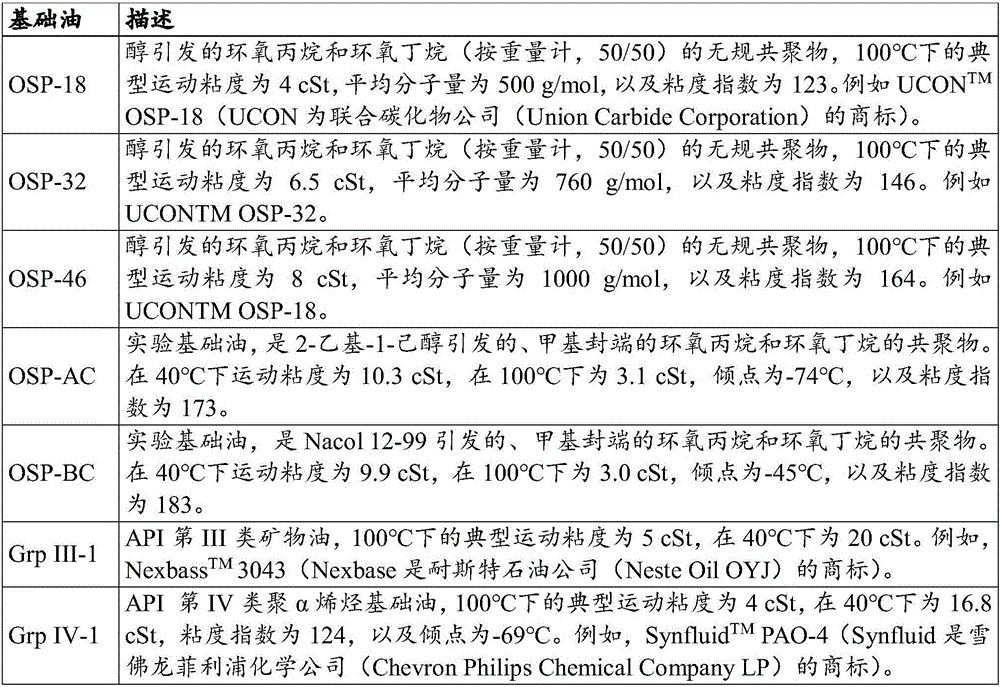

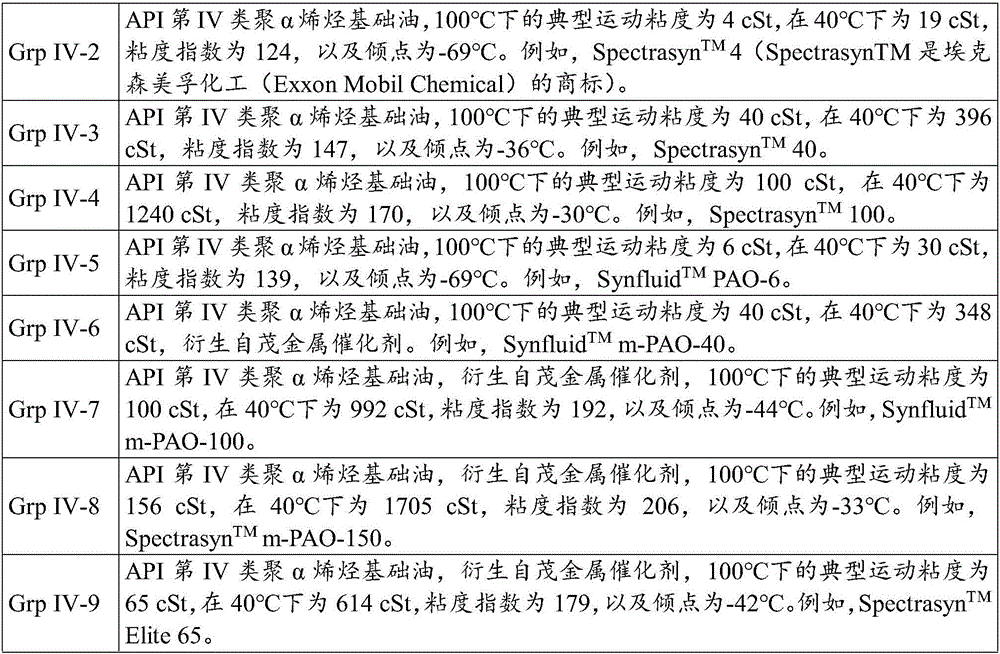

[0032] Table 1 identifies the base oils used in this example. Two experimental base oils (OSP-AC and OSP-BC) were prepared as follows.

[0033] OSP-AC

[0034] 1600 g of 2-ethyl-1-hexanol was added to a stainless steel reactor vessel, followed by 11.3 g of 85 wt% aqueous potassium hydroxide solution, and the mixture was heated to 115°C under a nitrogen blanket. At a temperature of 130° C. and a pressure of 500 kPa, a mixture of 2400 g of 1,2-propylene oxide and 240 g of 1,2-butylene oxide was charged into the reactor. The mixture was stirred and allowed to digest at 130°C for 12 hours. Residual catalyst was removed by filtration through a magnesium silicate filter bed at a temperature of 50°C to yield an intermediate with a kinematic viscosity of 17.7 cSt at 40°C, 3.81 cSt at 100°C, and a pour point of -59.0°C.

[0035] 5805 g of the above intermediate was added to a stainless steel reactor vessel. Add 2604 g of sodium methoxide solution (25 wt% sodium methoxide in methano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com