Stamping die with material ejection function

A technology for stamping dies and functions, applied in the field of stamping dies with the function of ejecting materials, to achieve the effects of improving stamping and discharging speed, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

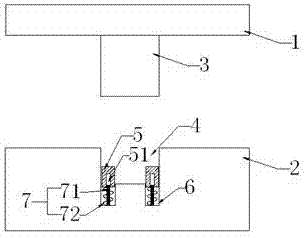

[0017] A stamping die with the function of ejecting materials, comprising an upper die 1 and a lower die 2, the lower surface of the upper die 1 has a punch 3, and the upper surface of the lower die 2 has a punch that matches the size of the punch 3 The stamping groove 4.

[0018] A jacking block 5 is also installed in the punching groove 4, and the two symmetrical side walls at the bottom of the punching groove 4 are chiseled with a cavity 6 that communicates with the bottom surface of the punching groove and matches the width of the jacking block 5, An elastic support mechanism 7 is also fixed in the cavity 6, and the lower end surface of the ejector block 5 is installed in the cavity 6 through the elastic support mechanism 7, and when the elastic support mechanism is in a free-to-expand state, the upper end surface of the ejector block is positioned at the punching position. in slot 4. The size relationship between the jacking block, the cavity and the stamping groove is: ...

Embodiment 2

[0022] The difference from Embodiment 1 is that the cavity 6 is located in the middle of the stamped groove 4 .

[0023] The working principle of the stamping die of the present invention is: in the process of stamping the stamping die, the ejector block is compressed by the punch until it is completely retracted into the cavity, and at this time the support spring in the spring telescopic mechanism is compressed to support The rod also goes deep into the hole groove of the ejector block; when the punch is punched, the punch is driven by the upper die to move upwards and leave the punching groove. During this process, the pressure from the punch on the ejector block disappears, supporting The spring rebound drives the ejector block to move upwards. On the one hand, the material belt is ejected out of the stamping groove, and on the other hand, the stamped product is jacked up, which is convenient for the manipulator to take out the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com