Assembly tooling for mechanical product part

A technology for assembling tooling and mechanical products, applied in the field of machinery, can solve problems such as poor adaptability of products and parts, six degrees of freedom position, complex attitude adjustment mechanism, etc., to reduce complexity, improve manufacturing efficiency and assembly quality, and improve flexibility The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

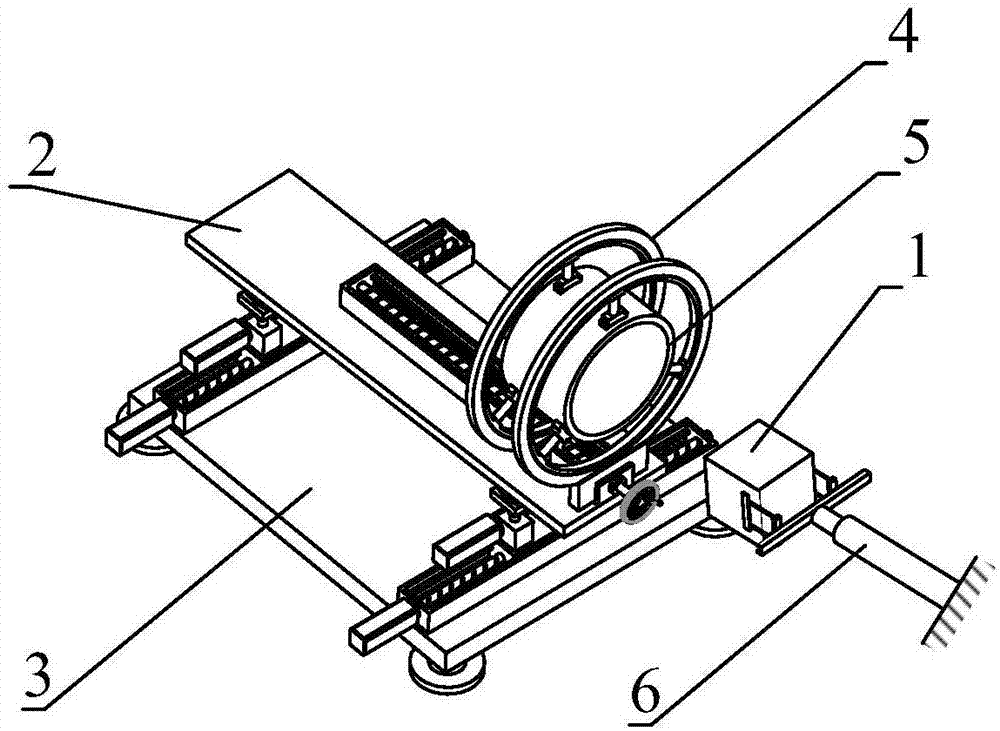

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment. An assembly tool for mechanical product parts described in this embodiment includes a product support mechanism 2, a position and posture adjustment mechanism 3, a cylindrical product support mechanism 4, a part clamping mechanism 6, and a thin-walled product support mechanism. Mechanism 8, supporting mechanism 2 is installed on the position and posture adjustment mechanism 3, and the cylindrical product support mechanism 4 and the thin-walled product support mechanism 8 are connected with the product support mechanism 2, and the product clamping mechanism 6 is arranged on the position and posture adjustment mechanism 3. side.

[0014] The product support mechanism 2 is used to realize the adjustment of the product's lateral and height positions, pitch and yaw attitude relative to the part 1 .

specific Embodiment approach 2

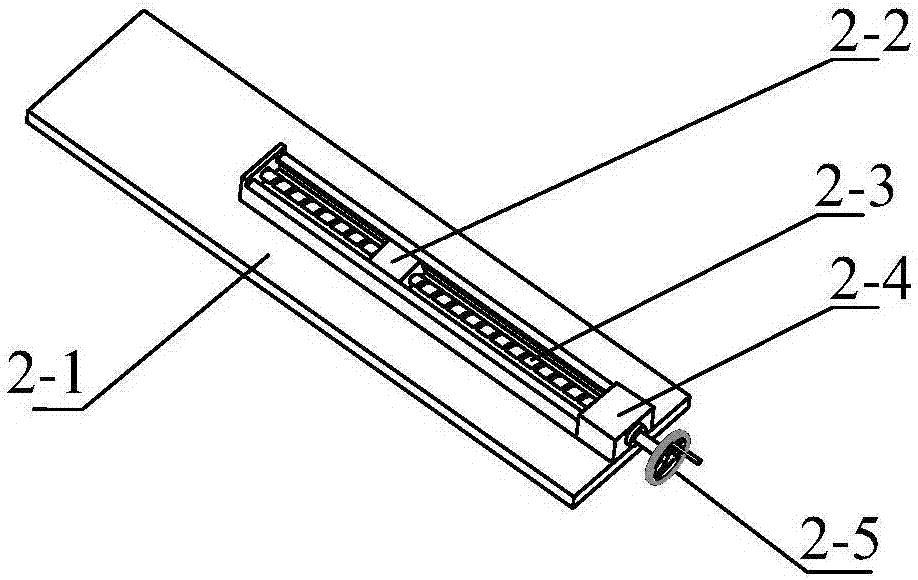

[0015] Specific implementation mode two: combination figure 2 Describe this embodiment, a product support mechanism 2 for assembly tooling of mechanical product parts described in this embodiment includes a support plate 2-1, a sliding support block 2-2, a ball screw and a guide rail 2-3, a fixed support Block 2-4 and hand wheel 2-5, support plate 2-1 is a rectangular plate body, ball screw and guide rail 2-3 are arranged on the upper surface of support plate 2-1, and ball screw and guide rail 2-3 along The center line of the length direction is parallel to the center line of the support plate 2-1 along the length direction, the fixed support block 2-4 is connected with the ball screw and one end of the guide rail 2-3, and the sliding support block 2-2 is installed on the ball screw and On the guide rail 2-3, and the sliding support block 2-2 can move linearly along the ball screw and the guide rail 2-3, and the hand wheel 2-5 is connected with the end of the ball screw and t...

specific Embodiment approach 3

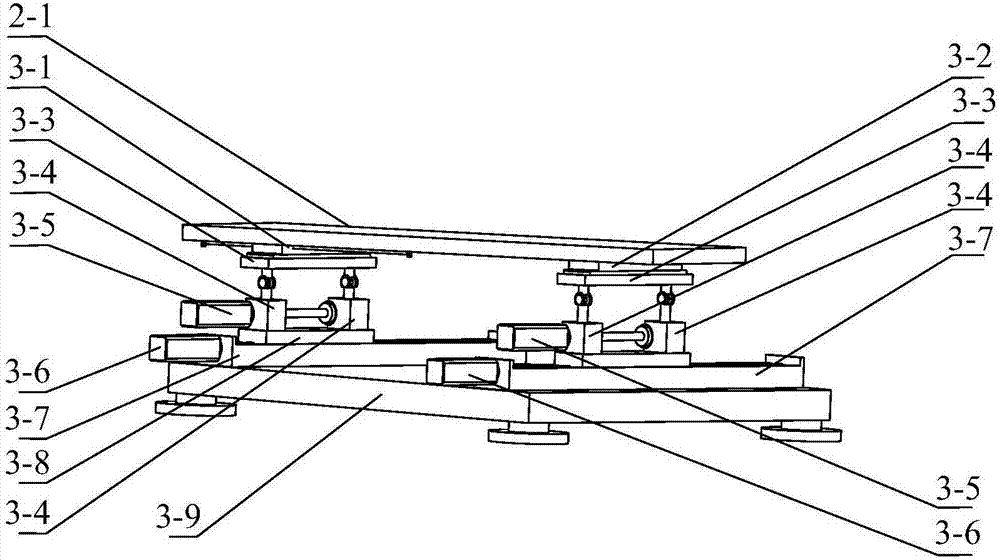

[0018] Specific implementation mode three: combination image 3 Describe the present embodiment. The position and posture adjustment mechanism 3 for the assembly tooling of mechanical product parts described in this embodiment includes a moving rotating plate 3-1, a fixed rotating plate 3-2, two sets of lifting plates 3-3, two Group elevator 3-4, two sets of lifting motors 3-5, two sets of horizontal motors 3-6, two sets of ball screws 3-7, two sets of sliders 3-8 and table body 3-9, moving rotating plate 3- 1 and the fixed rotating plate 3-2 are arranged side by side on the lower surface of the supporting plate 2-1, and the fixed rotating plate 3-2 is fixedly connected with the lower surface of the supporting plate 2-1, and the moving rotating plate 3-1 is connected to the supporting plate 2-1. The lower surface of 1 is connected by a linear guide rail; the lower surfaces of the moving rotating plate 3-1 and the fixed rotating plate 3-2 are respectively connected with a lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com