Green tire transfer system for tire production

A transfer system and raw tire technology, applied in the field of tire processing, can solve the problems of large labor consumption, high labor intensity, tire surface indentation, etc., to achieve the effect of reducing labor, improving work efficiency and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following embodiments may enable those skilled in the art to fully understand the present invention, but they do not limit the present invention to the scope of the described embodiments.

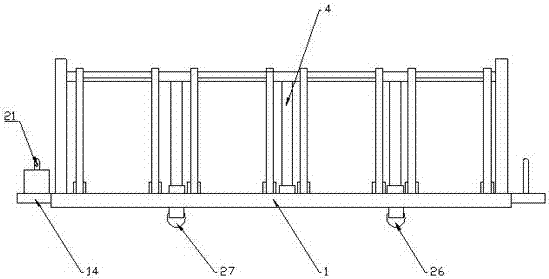

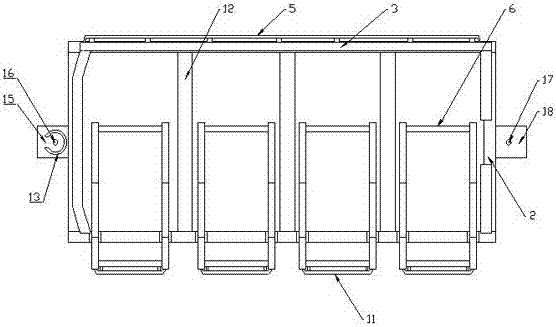

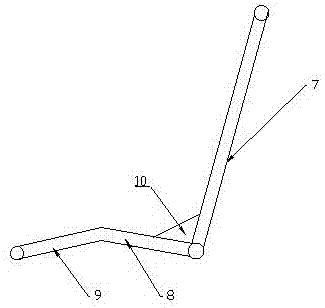

[0037] Such as Figure 1-Figure 6 A raw tire transfer system for tire production is shown, including

[0038] A transfer frame, the transfer frame includes a base, the base is a rectangular parallelepiped frame structure composed of a horizontal link 1 and a longitudinal link 2, and a fixed extension extending along the long axis of the base is installed at one end of the width of the base A bracket, the fixed bracket includes a horizontal link 3 arranged above the horizontal link 1, and a plurality of parallel vertical links 4 are connected between the horizontal link 3 and the adjacent horizontal link 1.

[0039] The outer end of the horizontal connecting rod 3 is also provided with a protective stop rod A5 extending along the long axis of the horizontal connecting rod 3, and a gap f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com