Double-clutch type steel cable tensioning mechanism

A tensioning mechanism and dual-clutch technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of cable wear, severe, complex structure, etc., and achieve the effect of prolonging service life and great economic application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

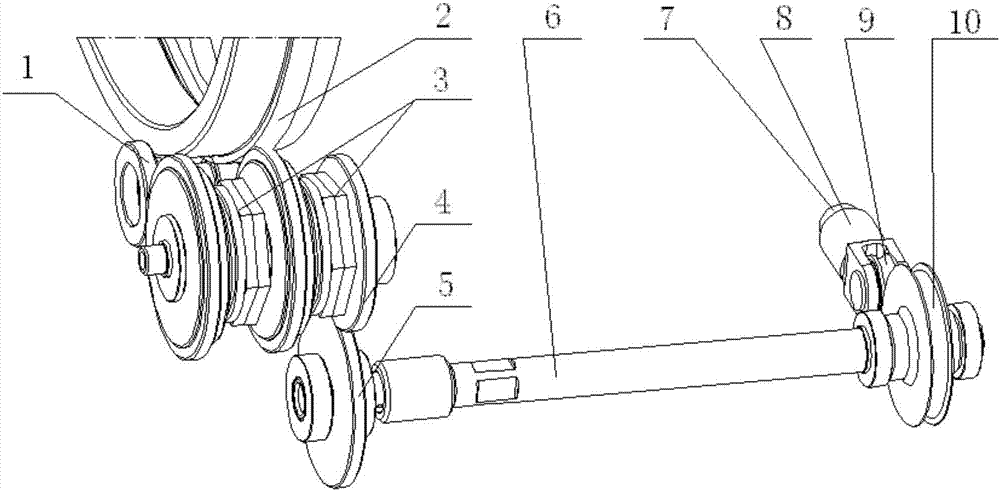

[0011] A double-clutch type cable tensioning mechanism is provided, the tensioning mechanism mainly includes a double idler gear (1), a reversing gear (2), a first driven gear, a second driven gear, and a one-way slip clutch ( 3), intermediate gear (4), transmission gear (5), connecting shaft (6), spring (7), driven wheel bracket (8), driven tension wheel (9), driving tension wheel (10);

[0012] The duplex idler gear (1) includes a coaxial and integrated bull gear and pinion; a gear shaft extends from the center of the intermediate gear (4); the first driven gear meshes with the bull gear, and the pinion and the reversing gear (2) meshing, the second driven gear meshes with the reversing gear (2); the first driven gear and the second driven gear are identical in structure, and are both connected to the gear shaft through the one-way slip clutch (3), the second driven gear The direction of the one-way slip clutch (3) of the first driven gear and the second driven gear is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com