A method of monitoring the bending degree of the boom

A technology of bending degree and boom, which is applied in the direction of measuring devices and instruments, can solve the problems of lack of low-cost feasible measures, deviation of the connection between the first and last sections, complexity of boom tube truss, etc., and achieve large economic application value, reduce accidents, and monitor the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

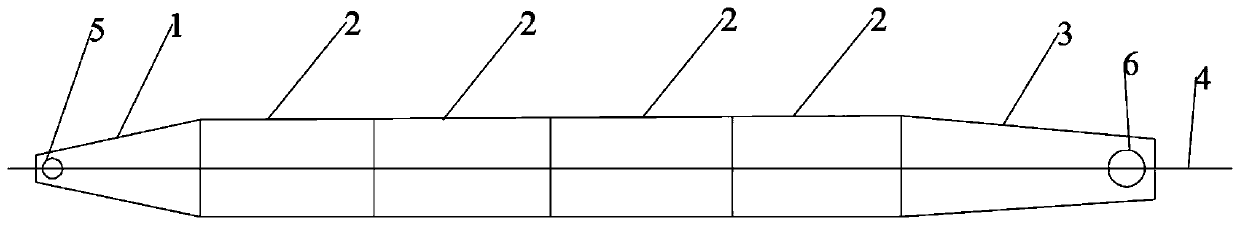

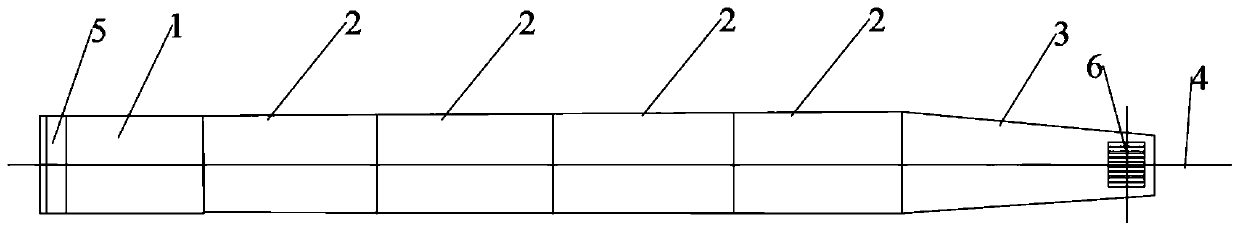

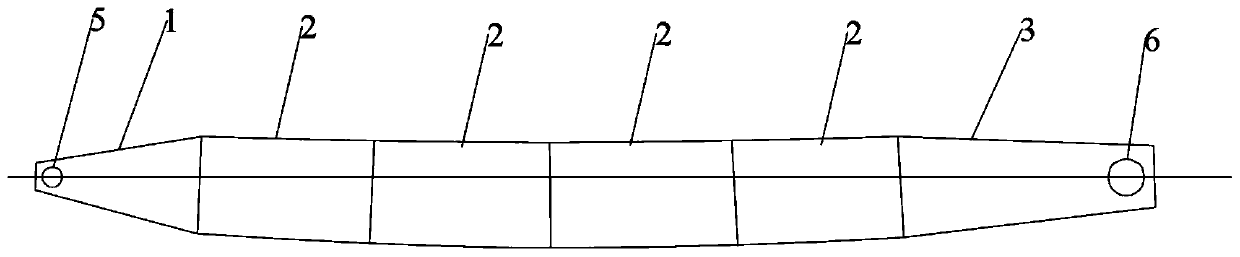

[0032] Below in conjunction with accompanying drawing, the present invention is illustrated

[0033] like Figure 5 to Figure 7 As shown, a method for monitoring the bending degree of the boom includes the following steps:

[0034] Step 1: Tie a wire rope stay cable 14 between the tail section 1 and head section 3 of the boom, fix one end of the wire rope stay cable 14 on the head section 3 through the front support of the wire rope stay cable 14, and the other end Tensioned on the tail section 1 by the spring device 22;

[0035] Step 2, a measurement point is set on the wire rope stay cable 14 at intervals, at each measurement point, such as Figure 7 As shown, the steel wire rope stay cable 14 is connected to the pipe truss of the boom around it by four stay rope displacement sensors 12, and the plurality of stay rope displacement sensors 12 are all located in a plane perpendicular to the steel wire rope stay cable 14;

[0036] Step 3, all stay rope displacement sensors 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com