Protective isolation device

A technology of protection isolation and guardrail, applied in the direction of fluid pressure actuating devices, servo motors, roads, etc., can solve the problems of inconvenient management, inflexible use, setting restrictions, etc., and achieve the effect of convenient control, simple structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

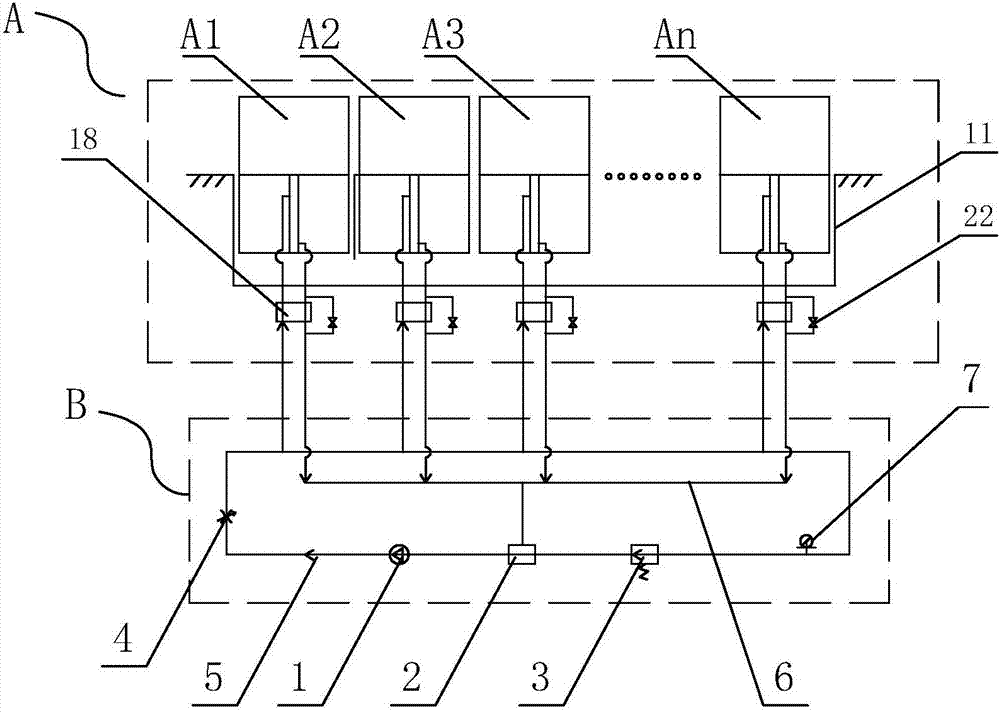

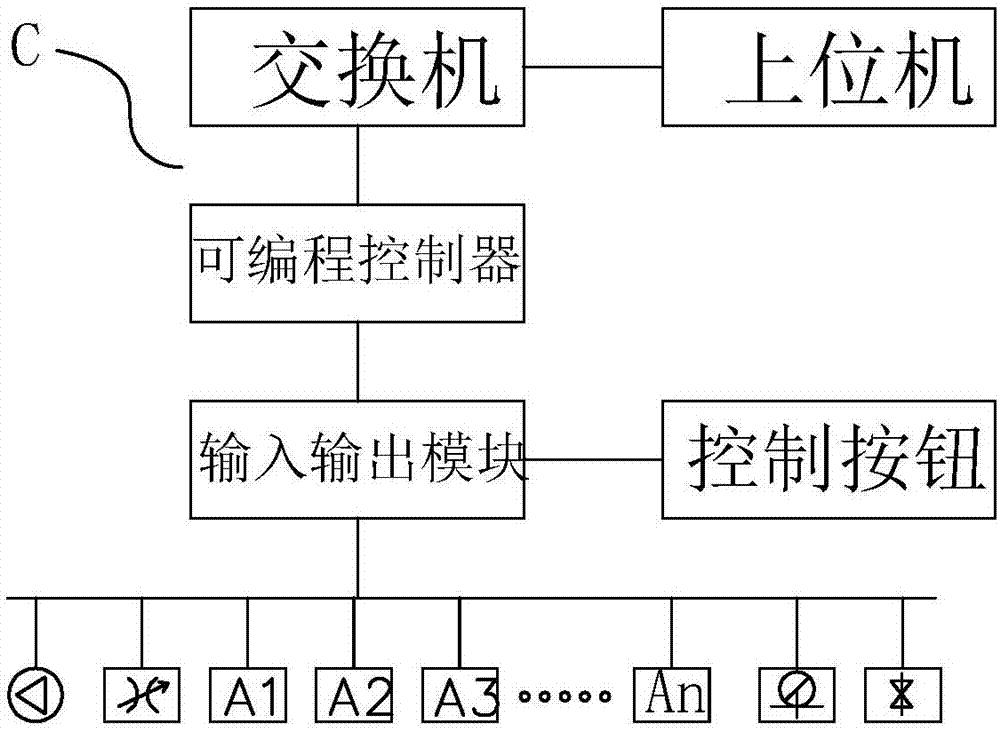

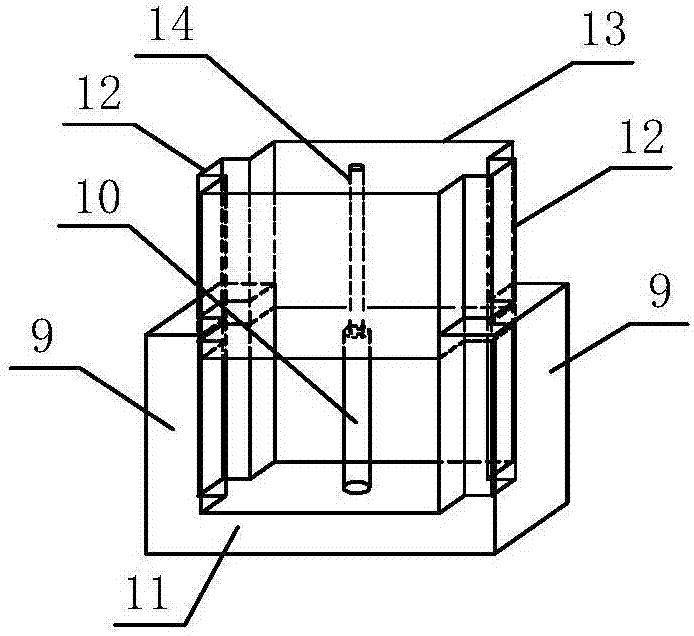

[0035] A protective isolation device, including a guardrail system A, a hydraulic system B and a control system C; the guardrail system is connected to the telescopic mechanism of the hydraulic system, and the hydraulic system is connected to the control system circuit and drives the telescopic mechanism under the control of the control system Lifting so as to drive the lifting of the guardrail system; the guardrail system includes 10 sets of guardrails arranged in sequence, and the n sets of guardrails are respectively connected with the n sets of telescopic mechanisms of the hydraulic system, and the n sets of guardrails have the same structure, including lifting bars 13, base 11 and the side plates 9 fixedly connected to the two sides of the base plate, the lifting rail is installed between the two side plates and is slidably matched with the two side plates, the lifting rail is a flat square frame with a downward opening, and its top surface is connected with the bottom plat...

Embodiment 2

[0041] A protective isolation device, the structure of which is basically the same as that of Embodiment 1, the difference is that: the two sides of the lifting rail are guide rails, and the matching side plates are provided with guide grooves, and the cross-sectional shape of the guide rails and guide grooves is square.

[0042] As a modification of the above embodiment, the cross-sectional shape of the guide rail and the guide groove can also be arc-shaped or triangular.

[0043] In the above embodiments, the number of guardrails installed can be increased or decreased according to actual needs. Generally, n is any integer between 1 and 100.

[0044] working principle

[0045]When the upper computer or the up button of the control button is activated, the hydraulic pump is started, the throttle valve is opened, and the hydraulic oil is distributed to the oil inlet pipe through the hydraulic pipe. Entering the lower part of the hydraulic cylinder, the hydraulic oil pushes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com