A Broadband Composite Magnetic Sensor

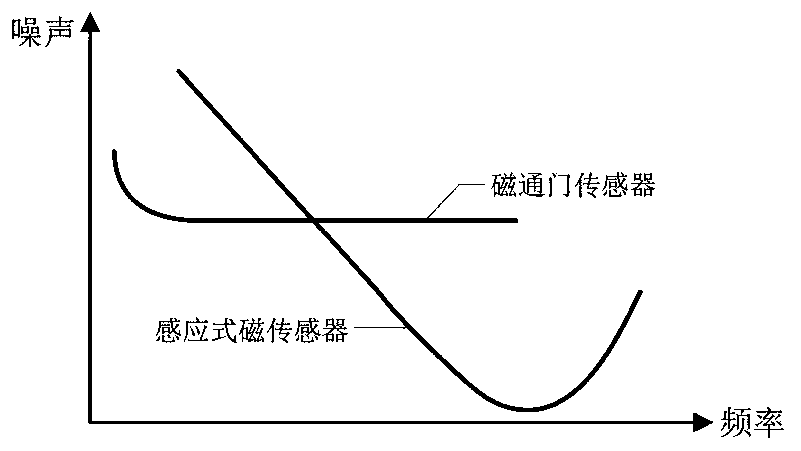

A technology of magnetic sensor and fluxgate sensor, which is applied in the direction of measuring geometric arrangement of magnetic sensing elements, instruments, scientific instruments, etc., can solve the problems of high noise, high noise, low sensor sensitivity, etc., and overcome the high frequency noise , Improve the sensitivity, the effect of wide-band low-noise magnetic field measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

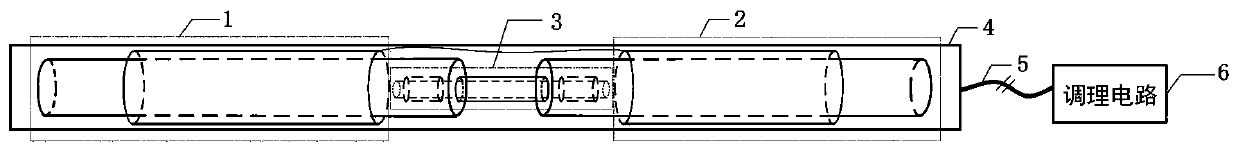

[0057] The broadband composite magnetic sensor is composed of an inductive magnetic sensor primary probe 1 and an inductive magnetic sensor secondary probe 2 installed at both ends of the shell 4 with a distance of 40mm, and the fluxgate sensor probe 3 is fixed on the inductive magnetic sensor primary probe 1 , The middle position of the inductive magnetic sensor secondary probe 2, the inductive magnetic sensor primary probe 1, the inductive magnetic sensor secondary probe 2 and the fluxgate sensor probe 3 are connected to the conditioning circuit 6 through a six-core shielded cable 5.

[0058] The primary probe 1 of the inductive magnetic sensor has the same structure as the secondary probe 2 of the inductive magnetic sensor.

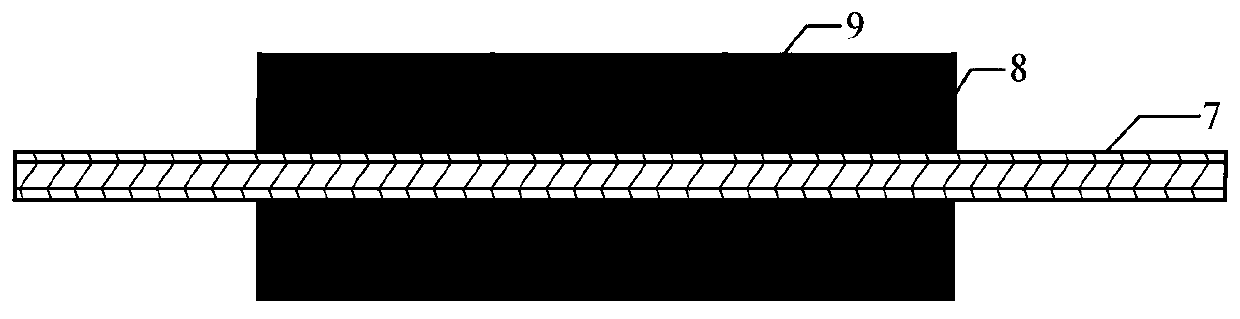

[0059] The primary probe 1 of the inductive magnetic sensor and the secondary probe 2 of the inductive magnetic sensor are installed in the center of the skeleton 8 of the inductive magnetic sensor with the hollow core 7 of the inductive magnetic sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com