Body of electric heating pipe, electric heating pipe structure, and manufacturing method

A production method and technology of electric heating pipes, which are applied in the directions of ohmic resistance heating parts, heating element materials, heating element shapes, etc., can solve the problems of electric leakage, the welding position is easily damped, and the pipe burst, and achieves good moisture-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

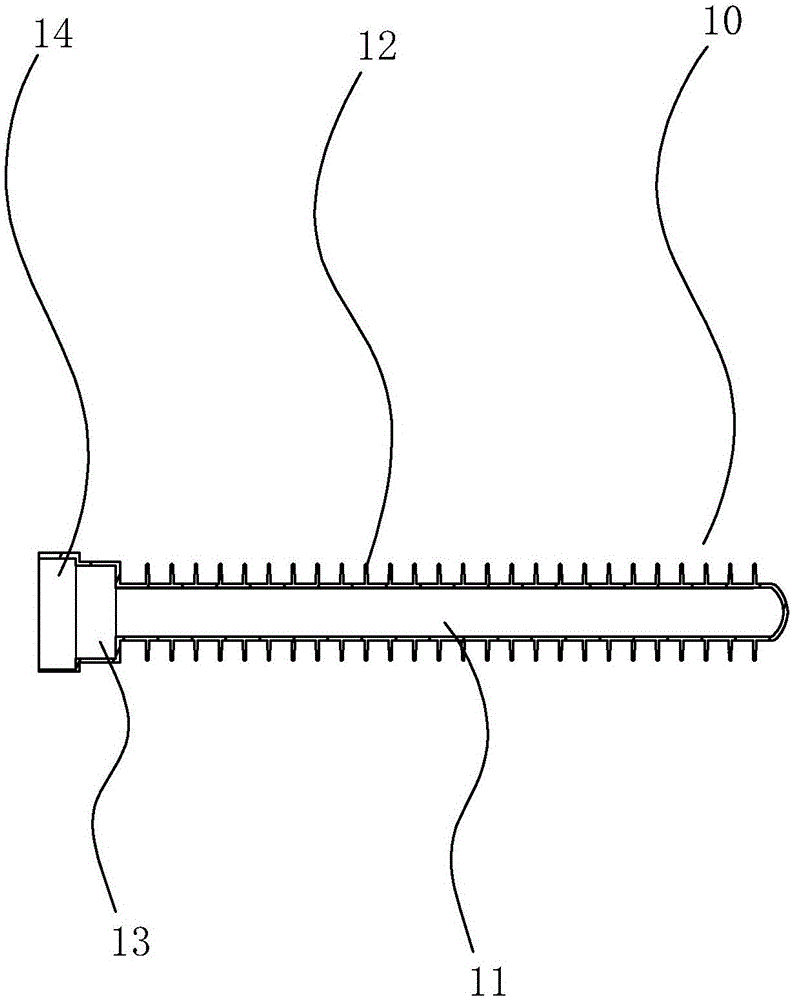

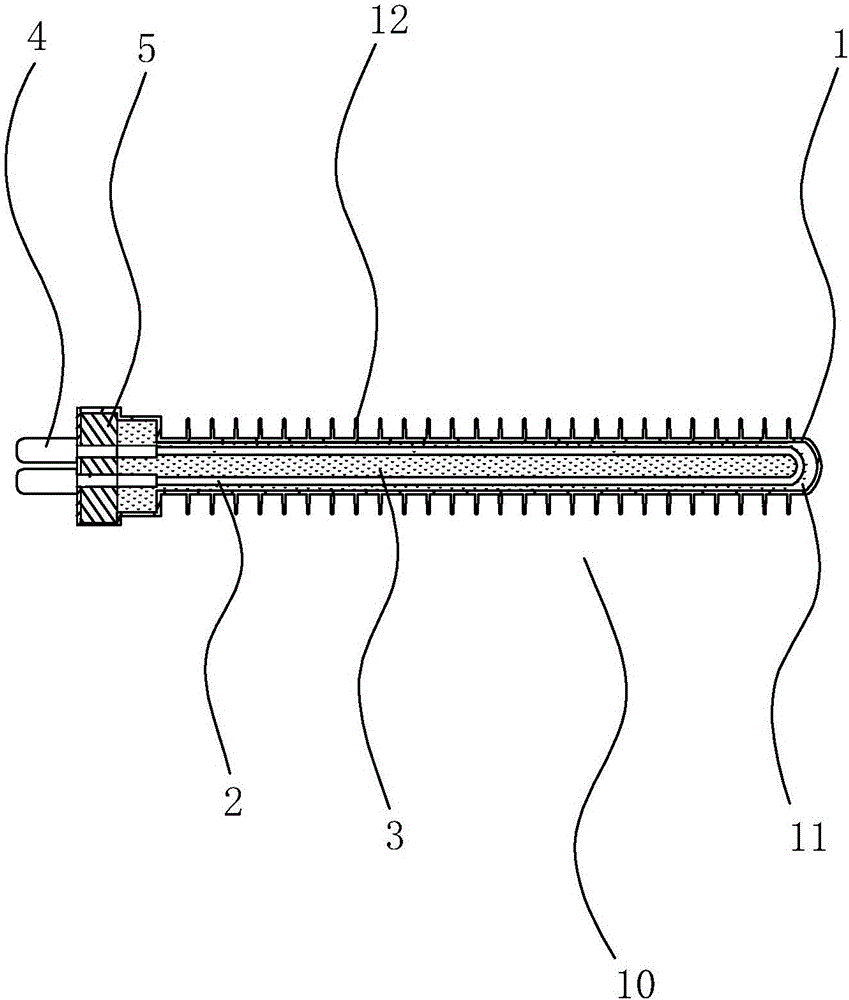

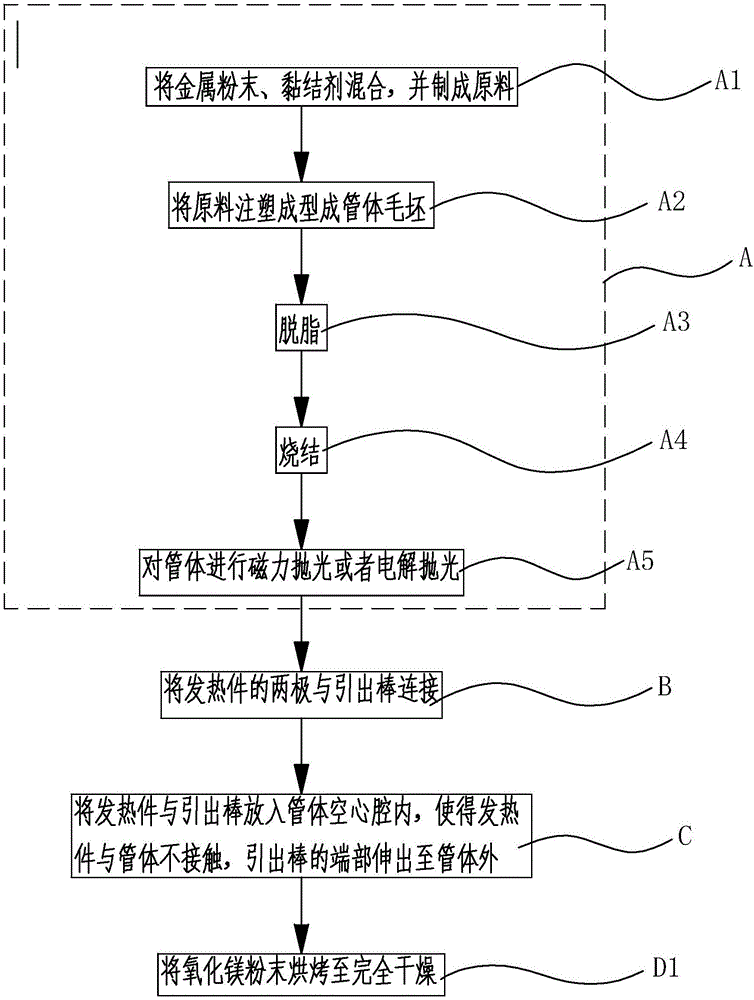

[0031] Such as figure 1 As shown, a tube body of an electric heating tube includes: a seamless tubular body 10 . The tubular body is provided with a hollow cavity 11 and is open at one end. It adopts a one-piece structure and can be formed by metal powder injection molding, precision casting or machining. The outer periphery of the tubular body 10 is also provided with a heat dissipation structure 12, which is a circular ring or a screw thread or a tooth-shaped concave-convex structure surrounding the outer periphery of the tubular body. In this embodiment, the heat dissipation structure is a ring surrounding the outer periphery of the tube.

[0032] In this embodiment, the open end of the tubular body is also provided with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com