A double-needle beverage brewing system and its brewing method

A beverage and brewing technology, which is applied in the field of double-needle beverage brewing system, can solve the problems of polluting the use environment, low taste of beverages, incomplete dissolution, etc., and achieve the effects of avoiding pollution, completely dissolving, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

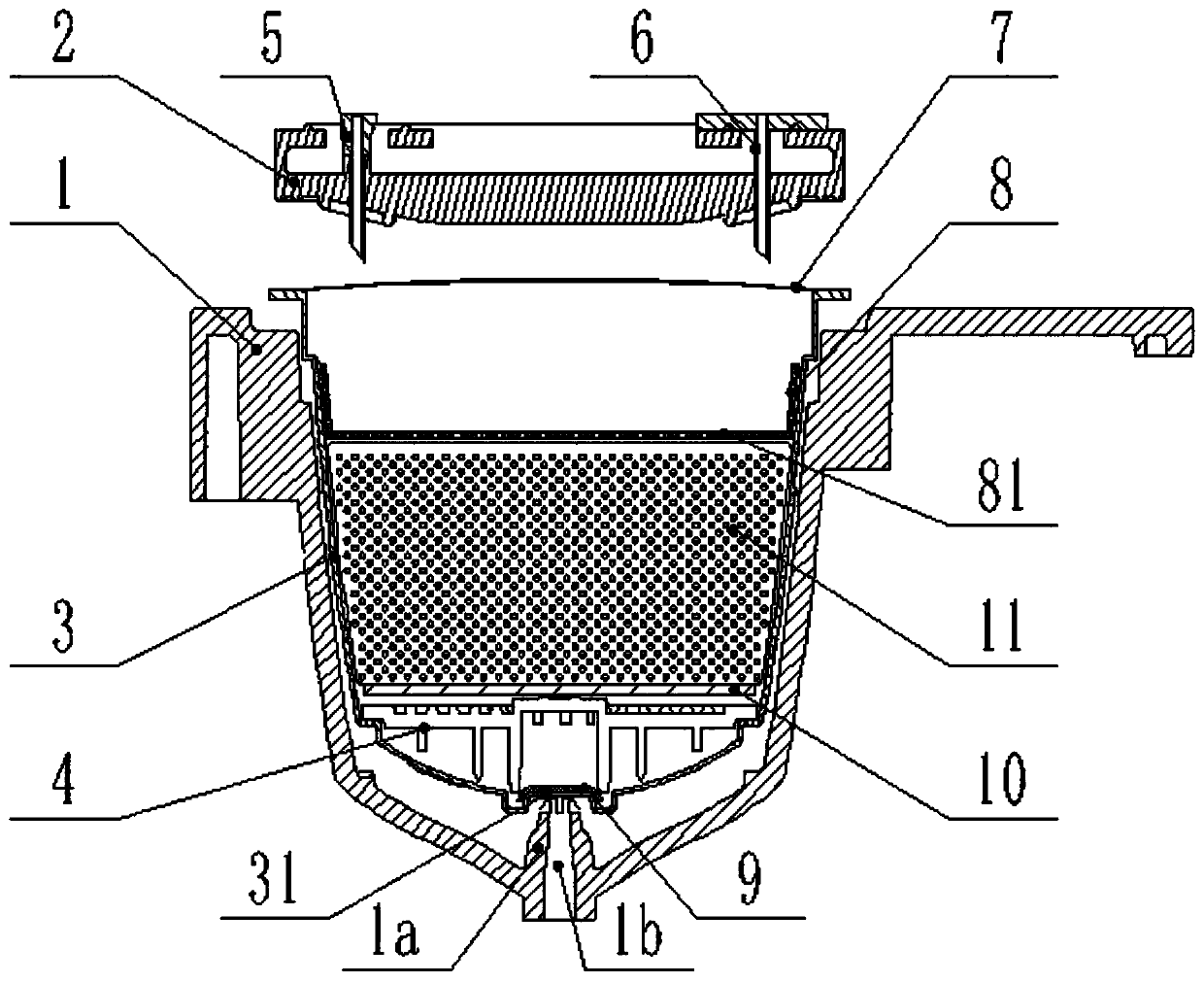

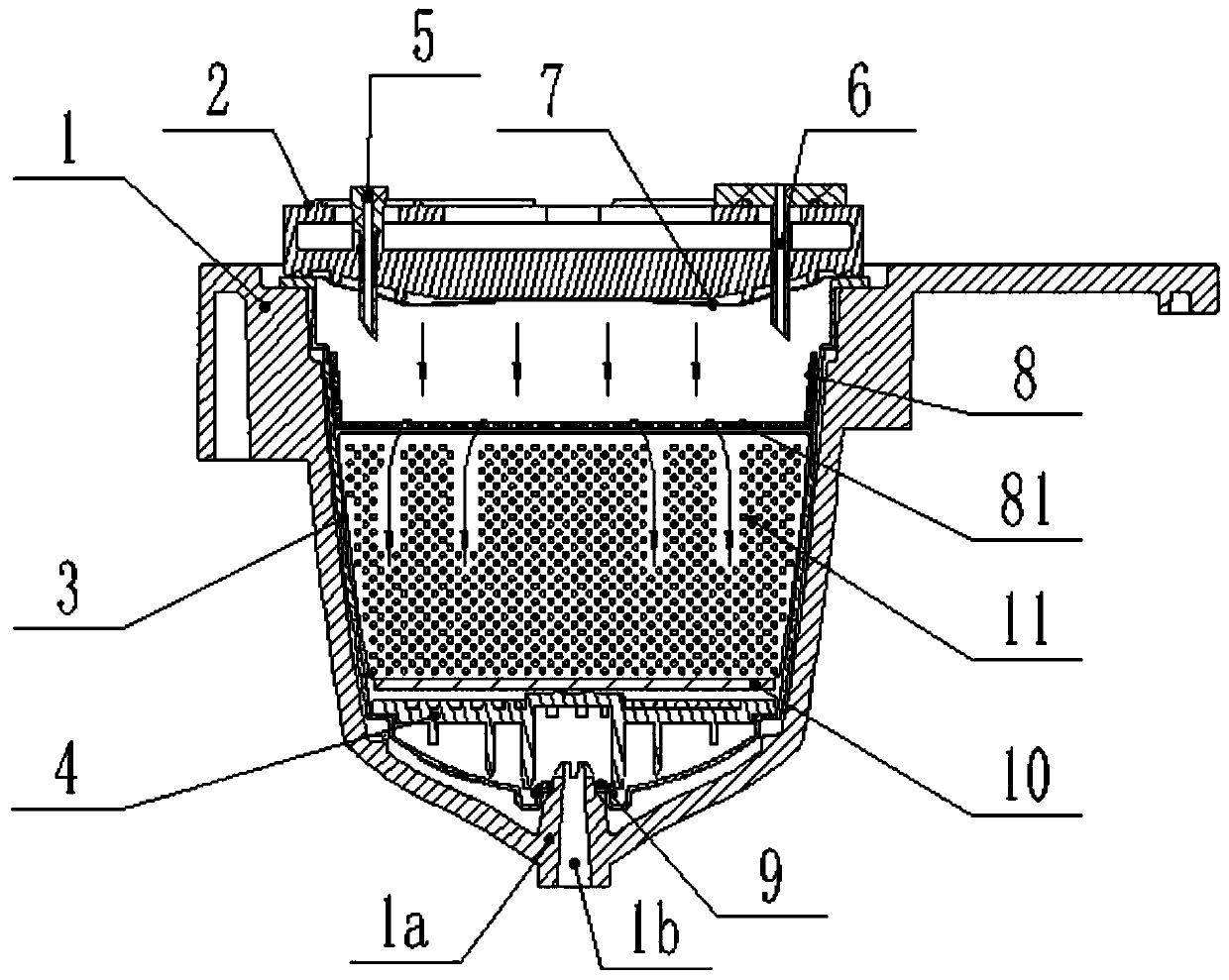

[0036] Embodiment one, such as figure 1 , figure 2 As shown, a double-needle beverage brewing system includes an extractor 1 with a cavity formed inside, a capsule push plate 2 arranged directly above the extractor 1 and a resistant The heat-resistant cup body 3; the heat-resistant cup body 3 is tightly connected with the extractor 1 by using the surrounding edges; the center of the bottom of the heat-resistant cup body 3 is provided with a circular through hole 31; the cavity of the heat-resistant cup body 3 The bottom of the bottom is provided with a filter tray 4; the central position of the filter tray 4 is provided with an opening; the capsule push plate 2 is provided with a first extraction needle 5 and a second extraction needle 6;

[0037]Preferably, in this embodiment, the first extraction needle 5 is set on the left side of the capsule push plate 2; the second extraction needle 6 is set on the right side of the capsule push plate 2; the first extraction needle 5 a...

Embodiment 2

[0052] Embodiment 2, when the material in the beverage precursor 11 is dairy products, the pressure of the first extraction needle 5 is injected into 30-200ml, preferably 50-100ml, and the material on the left side of the beverage precursor 11 is dissolved during brewing to form The empty area after the left part is dissolved; at the same time, the water gradually penetrates into the right cavity area, and then the second extraction needle 6 is pressured into 30-200ml, preferably 50-100ml, and the powder in the right cavity area collapses under the brewing force, The dissolution area in the chamber area increases, and the dissolution is more sufficient driven by a large amount of water flow.

[0053] One embodiment of the capsule is loaded with 20-25g of solid instant powder, the original one-needle brewing method, usually 10-15g of powder within the range of soluble needle brewing, and the remaining powder is usually viscous semi-soluble material wrapped powder , remaining in...

Embodiment 3

[0055] Example 3, first inject water into the inside through the second extraction needle 6 for 3-8 seconds, inject 4-8 percent of the cup capacity, about 20-40Ml of water, for initial dissolution, and then switch the first extraction needle 5 Brew in the same way as the second extraction needle 6. This method of repeated circulation of the left and right needles can accelerate the dissolution, and the repeated injection of water at the same frequency can increase the formation of a symmetrical vortex, so that it can be completely dissolved.

[0056] In the test of sampling 200 parts, 200 parts can be completely dissolved, and the material remaining on the filter paper in the heat-resistant cup body 3 is measured by drying and weighing. The measured attachment is less than 0.2g, which can be regarded as solid material in Under this method, it is completely dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com