Partial acid-soluble compound material plugging agent and preparation method and use method thereof

A plugging agent and acid-soluble technology, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well parts, etc., can solve the problems of high production cost and poor plugging performance of imported plugging agents, and achieve raw materials The effect of low price, improved processing efficiency, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

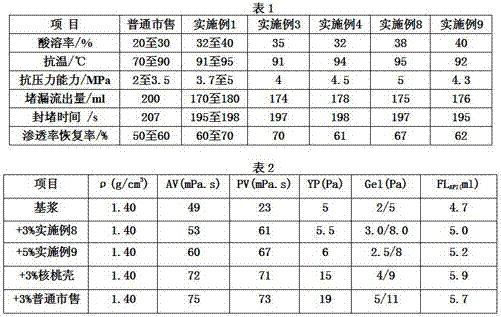

Examples

Embodiment 1

[0024] Embodiment 1: This part of the acid-soluble composite material plugging agent, the raw materials include 10 to 25 parts of mineral fibers with a mesh number of 20 to 60 mesh, and 10 to 30 parts of plant fibers with a mesh of 10 to 40 mesh in parts by weight. 5 parts to 15 parts of synthetic fiber from 10 mesh to 40 mesh, 10 to 15 parts of rigid material from 60 mesh to 80 mesh, 10 to 20 parts of rigid material from 80 mesh to 100 mesh and 15 parts of rigid material from 100 mesh to 120 mesh to 20 parts, the part of the acid-soluble composite material plugging agent is obtained by the following method: the required amount of mesh is 20 mesh to 60 mesh mineral fiber, 10 mesh to 40 mesh plant fiber, 10 mesh to 40 mesh Purpose synthetic fiber, 60-mesh to 80-mesh rigid material, 80-mesh to 100-mesh rigid material and 100-mesh to 120-mesh rigid material are mixed to obtain a partially acid-soluble composite material plugging agent.

Embodiment 2

[0025] Embodiment 2: This part of the acid-soluble composite material plugging agent, the raw materials include 10 or 25 parts of mineral fibers with a mesh number of 20 to 60 mesh, 10 or 30 parts of plant fibers with a mesh of 10 to 40 mesh in parts by weight. 5 or 15 parts of synthetic fiber from 10 mesh to 40 mesh, 10 or 15 parts of rigid material from 60 mesh to 80 mesh, 10 or 20 parts of rigid material from 80 mesh to 100 mesh and 15 parts of rigid material from 100 mesh to 120 mesh or 20 parts, said part of the acid-soluble composite material plugging agent is obtained by the following method: the required amount of mesh is 20 mesh to 60 mesh mineral fiber, 10 mesh to 40 mesh plant fiber, 10 mesh to 40 mesh Purpose synthetic fiber, 60-mesh to 80-mesh rigid material, 80-mesh to 100-mesh rigid material and 100-mesh to 120-mesh rigid material are mixed to obtain a partially acid-soluble composite material plugging agent.

Embodiment 3

[0026] Embodiment 3: This part of the acid-soluble compound material plugging agent, the raw materials include 10 parts of mineral fibers with a mesh number of 20 mesh to 60 mesh, 30 parts of plant fibers with a mesh size of 10 mesh to 40 mesh, and 10 mesh to 40 mesh. 5 parts of synthetic fiber, 10 parts of rigid material from 60 mesh to 80 mesh, 10 parts of rigid material from 80 mesh to 100 mesh, and 20 parts of rigid material from 100 mesh to 120 mesh. The method obtains: the required amount of mesh is mineral fiber of 20 mesh to 60 mesh, plant fiber of 10 mesh to 40 mesh, synthetic fiber of 10 mesh to 40 mesh, rigid material of 60 mesh to 80 mesh, rigid material of 80 mesh to 100 mesh After the material is mixed with a rigid material of 100 mesh to 120 mesh, a plugging agent of partially acid-soluble composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com