Water-cooled magnet safety protection method

A safety protection and water-cooling technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve problems that are not clearly explained, and achieve good fit and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation

[0030] The specific embodiment of the present invention is explained in further detail below in conjunction with accompanying drawing:

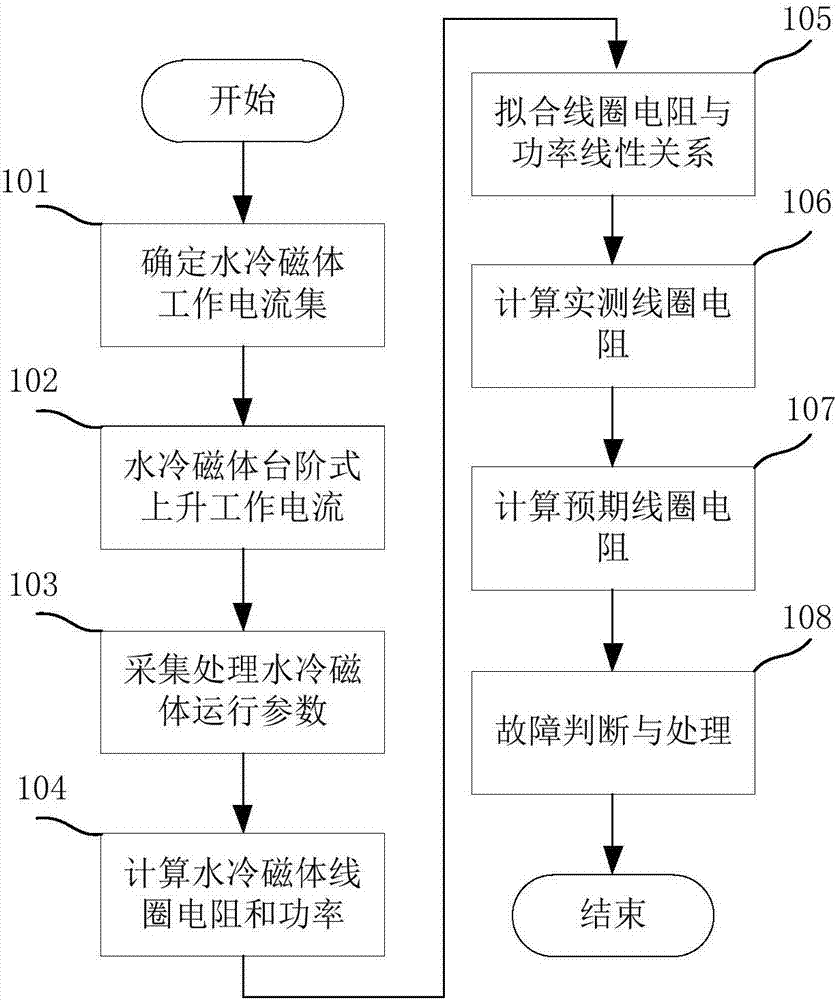

[0031] figure 1 It is the protection process for the water-cooled magnet when it is running for the first time, including:

[0032] Step 101: Divide the working current of the water-cooled magnet at equal intervals from the minimum value to the maximum value, and determine the working current set I of the water-cooled magnet i (i=1,2,...,n, n≥5), where I 1 is the minimum operating current, I n is the maximum operating current.

[0033] Step 102: The cooling water flow rate and the magnet inlet water temperature remain constant, and the operating current of the water-cooled magnet is changed from the minimum value I 1 Step up to the highest current I n period.

[0034] Step 103: Collect the running parameters of the water-cooled magnet, including operating current, coil terminal voltage, cooling water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com