Safety helmet with fine sand dust prevention function for oil exploitation

A safety helmet and sand dust technology, applied in the field of safety helmets, can solve the problems of reducing work efficiency, unable to prevent sand and dust, and workers unable to work normally, and achieves the effect of convenient cleaning, avoiding dry and cracked skin, and ensuring health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

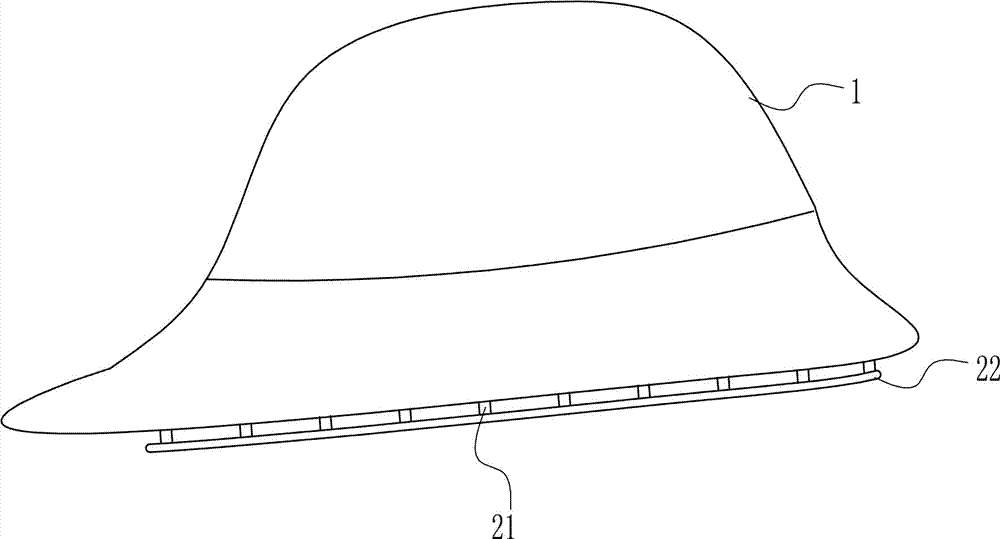

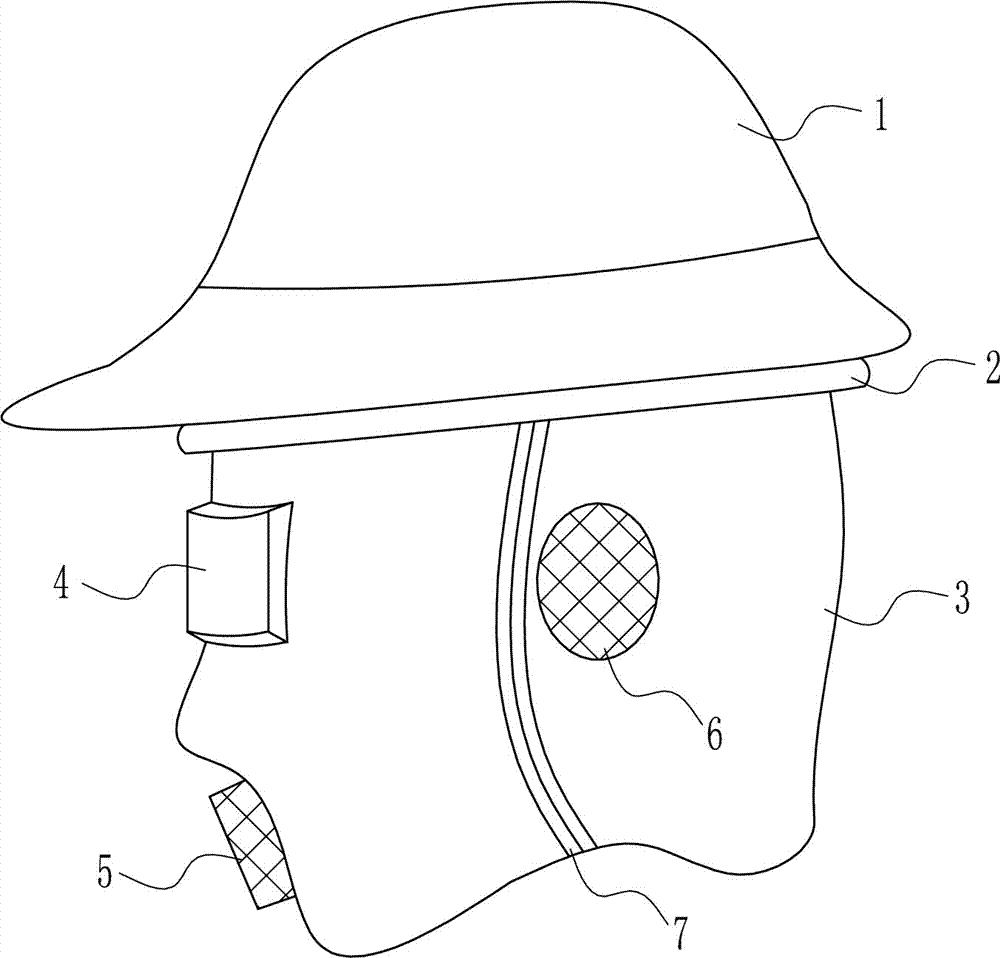

[0036] A safety helmet with anti-sand and dust function for oil exploitation, such as Figure 1-6 As shown, it includes a cap body 1, a first connector 2, a mask 3, a transparent window 4, a dustproof ventilation cover 5, and a second connector 7. The bottom of the cap body 1 is provided with a detachable mask 3, and the mask 3 and the cap The body 1 is connected by the first connector 2, the eyes of the mask 3 are provided with a transparent window 4, the mouth of the mask 3 is provided with a dust-proof ventilation cover 5, the ears of the mask 3 are provided with a listening port 6, and the mask 3 It is provided with a second connecting piece 7 that can be expanded or closed.

Embodiment 2

[0038] A safety helmet with anti-sand and dust function for oil exploitation, such as Figure 1-6 As shown, it includes a cap body 1, a first connector 2, a mask 3, a transparent window 4, a dustproof ventilation cover 5, and a second connector 7. The bottom of the cap body 1 is provided with a detachable mask 3, and the mask 3 and the cap The body 1 is connected by the first connector 2, the eyes of the mask 3 are provided with a transparent window 4, the mouth of the mask 3 is provided with a dust-proof ventilation cover 5, the ears of the mask 3 are provided with a listening port 6, and the mask 3 It is provided with a second connecting piece 7 that can be expanded or closed.

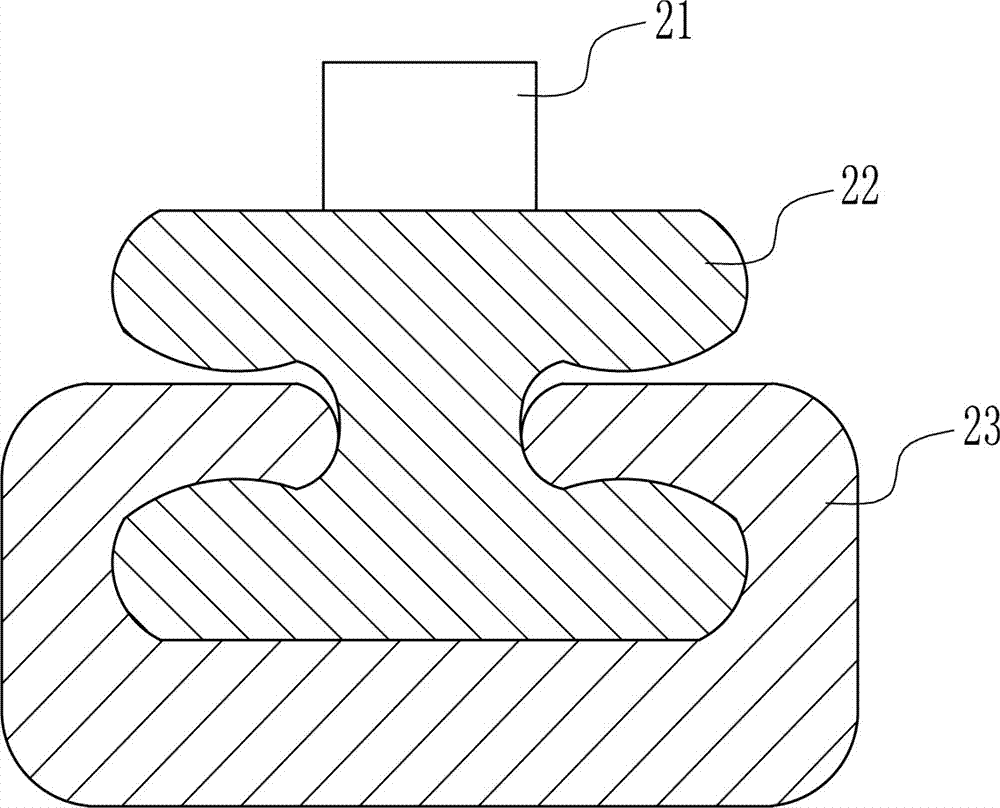

[0039] The first connecting piece 2 includes a connecting rod 21, an I-shaped guide bar 22 and a concave clip bar 23. The circumferential direction of the bottom of the cap body 1 is evenly spaced with connecting rods 21, and the bottom of the connecting rod 21 is connected with an I-shaped guide bar...

Embodiment 3

[0041] A safety helmet with anti-sand and dust function for oil exploitation, such as Figure 1-6 As shown, it includes a cap body 1, a first connector 2, a mask 3, a transparent window 4, a dustproof ventilation cover 5, and a second connector 7. The bottom of the cap body 1 is provided with a detachable mask 3, and the mask 3 and the cap The body 1 is connected by the first connector 2, the eyes of the mask 3 are provided with a transparent window 4, the mouth of the mask 3 is provided with a dust-proof ventilation cover 5, the ears of the mask 3 are provided with a listening port 6, and the mask 3 It is provided with a second connecting piece 7 that can be expanded or closed.

[0042] The first connecting piece 2 includes a connecting rod 21, an I-shaped guide bar 22 and a concave clip bar 23. The circumferential direction of the bottom of the cap body 1 is evenly spaced with connecting rods 21, and the bottom of the connecting rod 21 is connected with an I-shaped guide bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com