Biomimetic enzyme absorbent for removing elemental mercury in flue gas and its preparation method and application

A biomimetic enzyme and absorbent technology, applied in separation methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as easy corrosion of equipment, easy decomposition, and easy disproportionation reactions, so as to solve mercury pollution and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

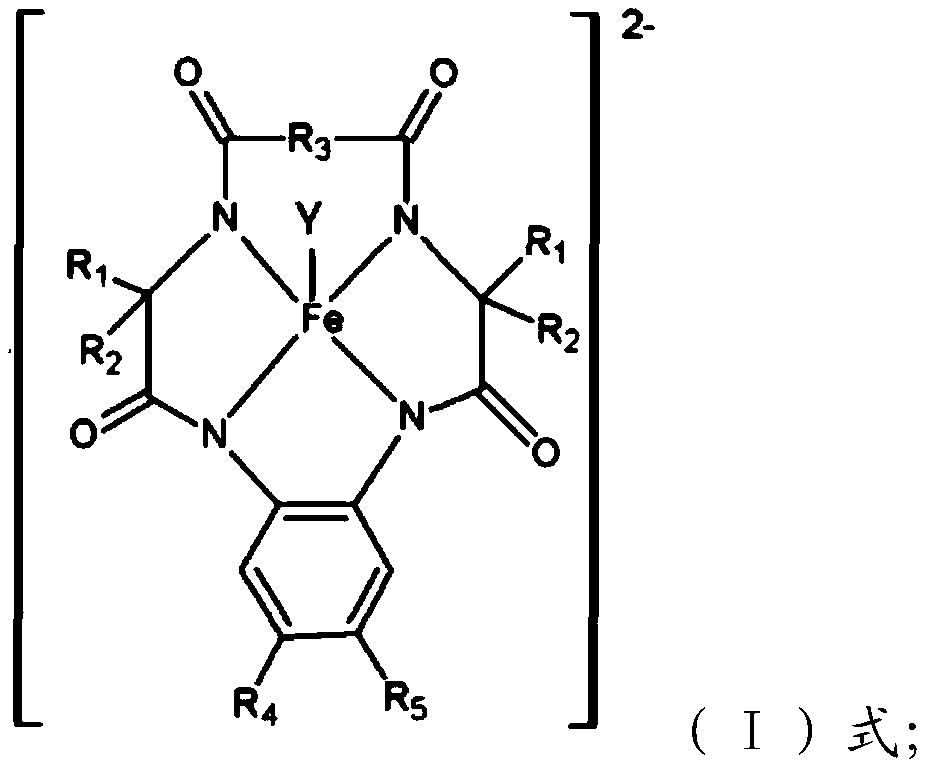

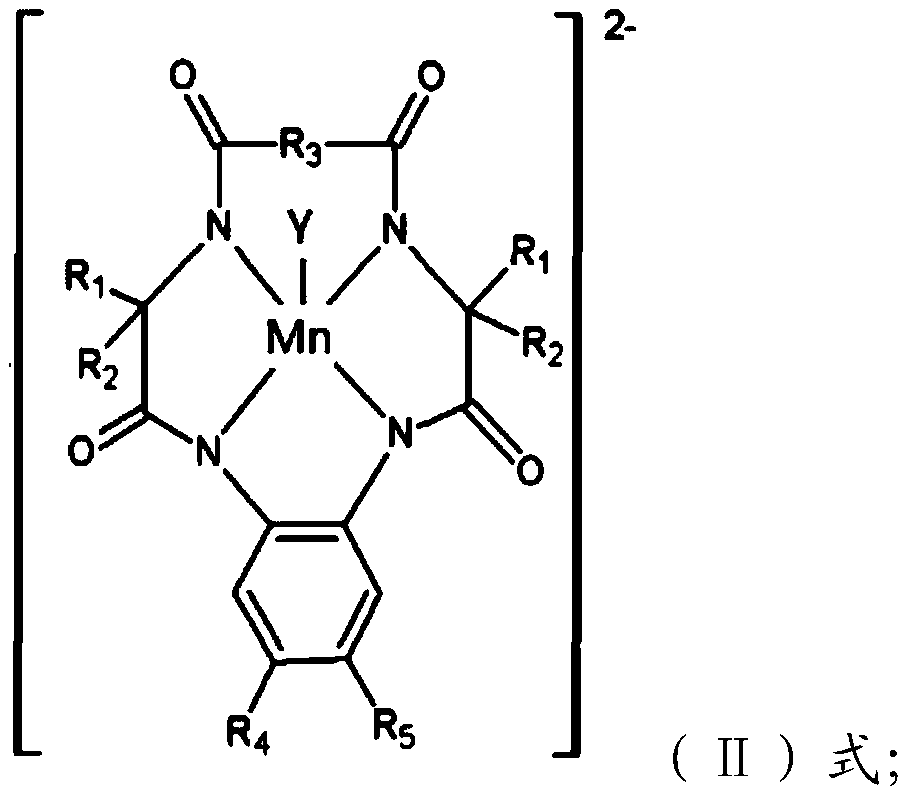

[0050] At pH 7.0, 0.01mol / L phosphate buffer solution 150ml, add 200mg of four amido macrocyclic iron complexes (Y is Cl; R 1 R 2 for CH 3 , R 3 for H, R 4 R 5 Both are H. ), a constant temperature of 25°C, and then adding 16ml of H 2 o 2 (Concentration: 30%), adjust the pH value of the solution to 9, mechanically stir to fully react, add deionized water to obtain 2L of absorbent. Wherein, the mass concentration of hydrogen peroxide is 78mmol / L, and the amount of tetraamide macrocyclic iron complex is 100ppm.

[0051] Then, the prepared absorbent is contacted with flue gas for 5 seconds at a reaction temperature of 20° C. and a reaction pH of 9 using a bubbling reactor.

[0052] The results show that when the initial concentration of elemental mercury in flue gas is 100μg / m 3 At that time, the mercury content in the flue gas after the reaction was measured by the QM201H coal-fired flue gas mercury detector, and the results showed that the removal rate of elemental mer...

Embodiment 2

[0054] At pH 7.0, 0.01mol / L phosphate buffer solution 350ml, add 400mg of four amido macrocyclic iron complexes (Y is H 2 O; R 1 R 2 for CH 3 , R 3 CH 2 , R 4 R 5 Both are H), keep the temperature at 25°C, then add 4ml of H 2 o 2 (Concentration: 30%), adjust the pH value of the solution to 10, mechanically stir to fully react, add deionized water to obtain 2L of absorbent. Among them, the H in the absorbent 2 o 2 The concentration of the substance is 19.6mmol / L, and the amount of the tetraamido macrocyclic iron complex is 200ppm.

[0055] Then, the prepared absorbent is contacted with flue gas for 2 seconds at a reaction temperature of 40° C. and a reaction pH of 8 using a bubbling reactor.

[0056] The results show that when the initial concentration of elemental mercury in flue gas is 100μg / m 3 At that time, the mercury content in the flue gas after the reaction was measured by using the QM201H coal-fired flue gas mercury detector, and the results showed that the...

Embodiment 3

[0058] At pH 7.0, 0.01mol / L phosphate buffer solution 1500ml, add 200mg of four amido macrocyclic iron complexes (Y is H 2 O; R 1 R 2 for CH 3 , R 3 CH 2 , R 4 for COOH, R 5 for CH 3 ), keep the temperature at 25°C, then add 80g of sodium percarbonate, adjust the pH value of the solution to 9, mechanically stir to fully react, add deionized water, and obtain 10L of absorbent. Among them, the H generated in the absorbent 2 o 2 The substance concentration is 77mmol / L, and the amount of tetraamido macrocyclic iron complex is 20ppm.

[0059] Then, the prepared absorbent is contacted with flue gas for 4 seconds at a reaction temperature of 40.8° C. and a reaction pH of 8.81 using a bubbling reactor.

[0060] The results show that when the initial concentration of elemental mercury in flue gas is 100μg / m 3 When using the QM201H coal-fired flue gas mercury detector to measure the mercury content in the flue gas after the reaction, the results show that the removal rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com