High-pressure water descaling device

A high-pressure water descaling and descaling box technology, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems that cannot meet the high surface quality requirements and difficult production requirements, and achieve the resolution of descaling quality problems, Avoid the effect of accuracy and reasonable control of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

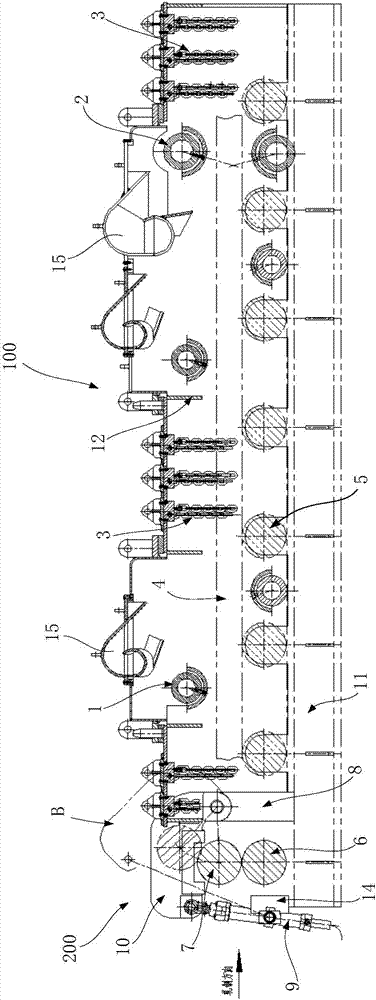

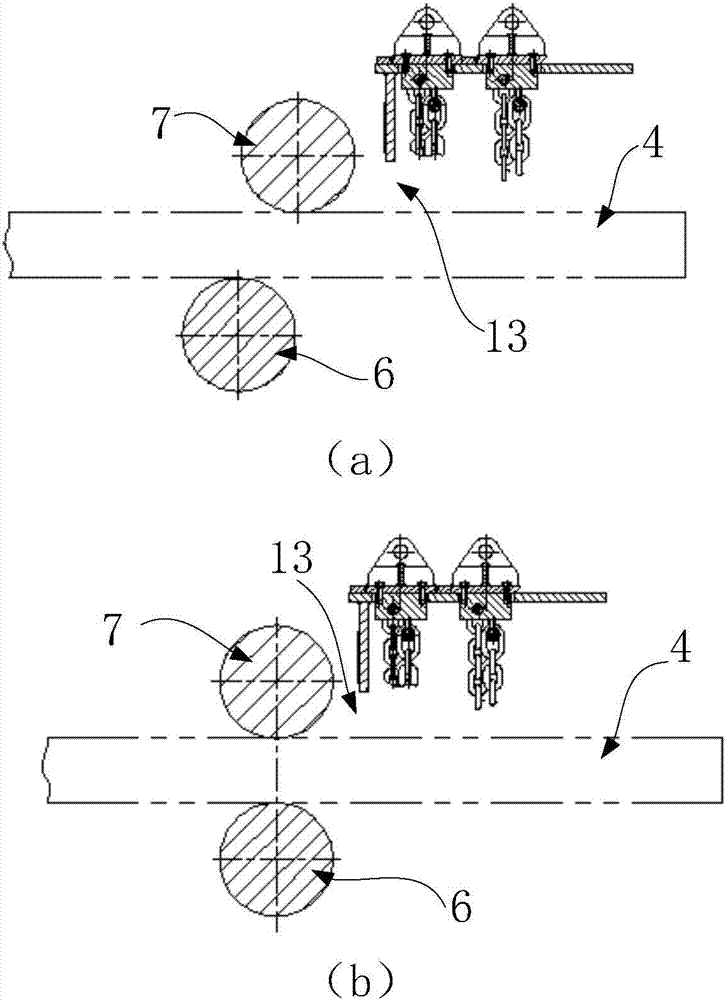

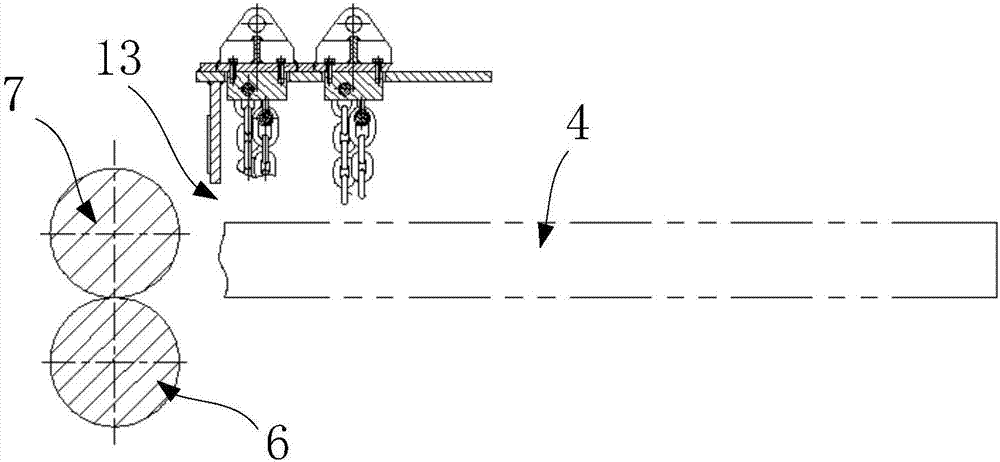

[0043] like figure 1 As shown, a high-pressure water descaling device includes a descaling box body 100, and the descaling box body 100 is provided with at least two kinds of pressure descaling header groups, and each pressure descaling header group is a row or There are multiple rows, and a special water sealing device 200 is provided at the entrance of the descaling box body 100 .

[0044] The descaling header group with different pressures is illustrated by taking the descaling header group with two pressures as an example, such as the first descaling header group 1 with relatively low pressure, and the second descaling header group with relatively high pressure Tube group 2, the number of the descaling header groups is not limited, it can be two rows of the first descaling header group 1, one row of the second descaling header group 2; or one row of the first descaling header group 1. Two rows of second descaling header groups. 2. It can also be in other numbers and combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com