Full-automatic screw assembling equipment

An assembly equipment and fully automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low labor efficiency, low labor efficiency, and large difficulties, and achieve improved assembly speed and efficiency, practicality and creativity Strong, improve the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of those skilled in the art, the present invention will be further described with reference to the following examples, and the content mentioned in the embodiments is not a limitation of the present invention.

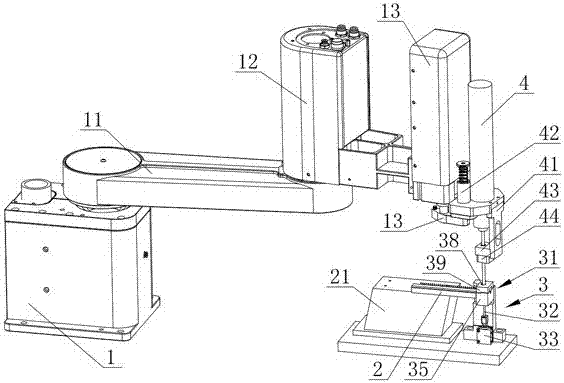

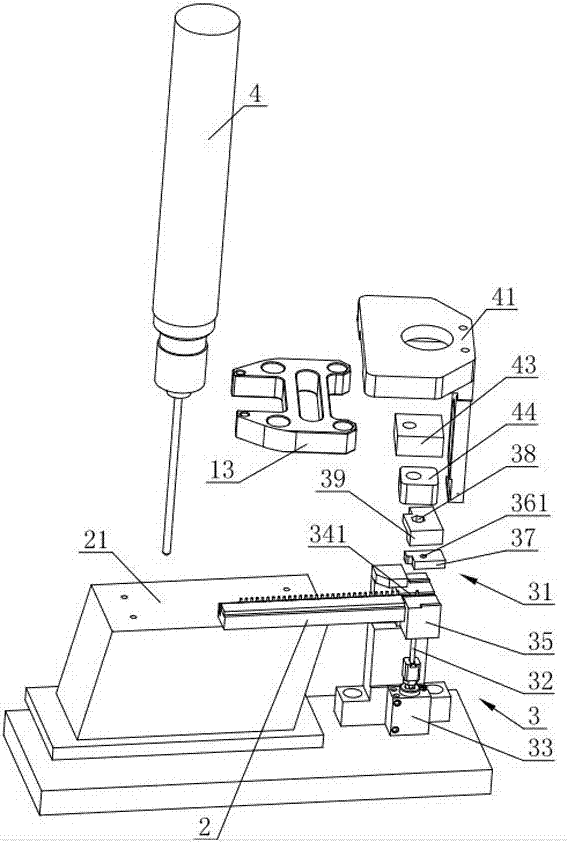

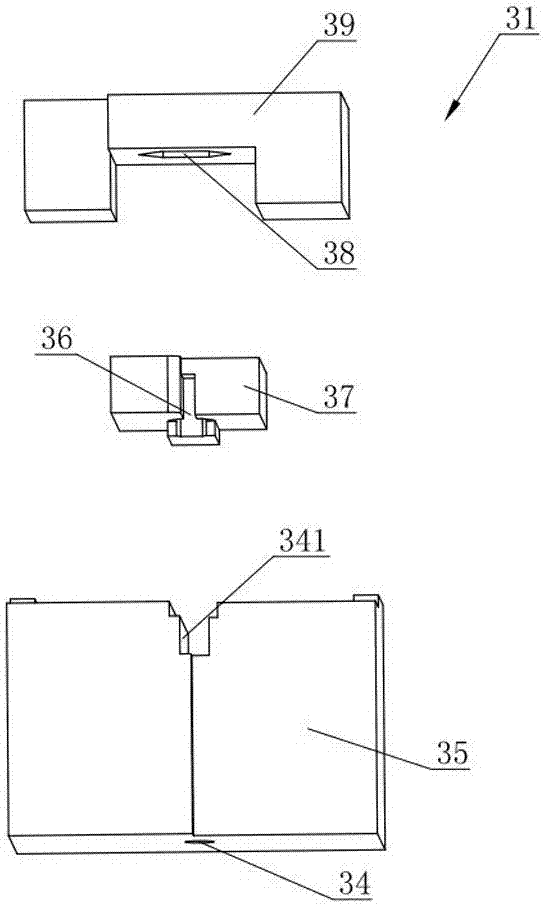

[0016] Such as Figure 1 to Figure 3 As shown, a fully automatic screw assembly equipment includes a driving device 1 installed on a frame, a first mechanical arm 11 installed on the driving device 1 and capable of swinging, and a second mechanical arm installed on the first mechanical arm 11 capable of swinging Arm 12, a feeding chute 2 installed on the frame and connected to the feeding tray, and a feeding device 3 connected to the other end of the feeding chute 2. The second mechanical arm 12 is also installed with a lifting arm 13 and movably connected to the lifting The assembling claw 4 of the arm 13, the feeding device 3 includes a feeding seat 31 connected to the feeding slide 2, a feeding rod 32 penetrating the feed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap