Flexible polishing constant-force control device driven by double actuators

A control device and actuator technology, which is applied to grinding automatic control devices, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of slow response, poor force control ability, and insufficient adjustment accuracy, and achieves smooth grinding and improved Grinding quality, effect of high force adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The dual-actuator-driven flexible grinding constant force control device of the present invention is used for grinding and processing the side wall of a workpiece by an industrial robot to improve the surface quality of the workpiece.

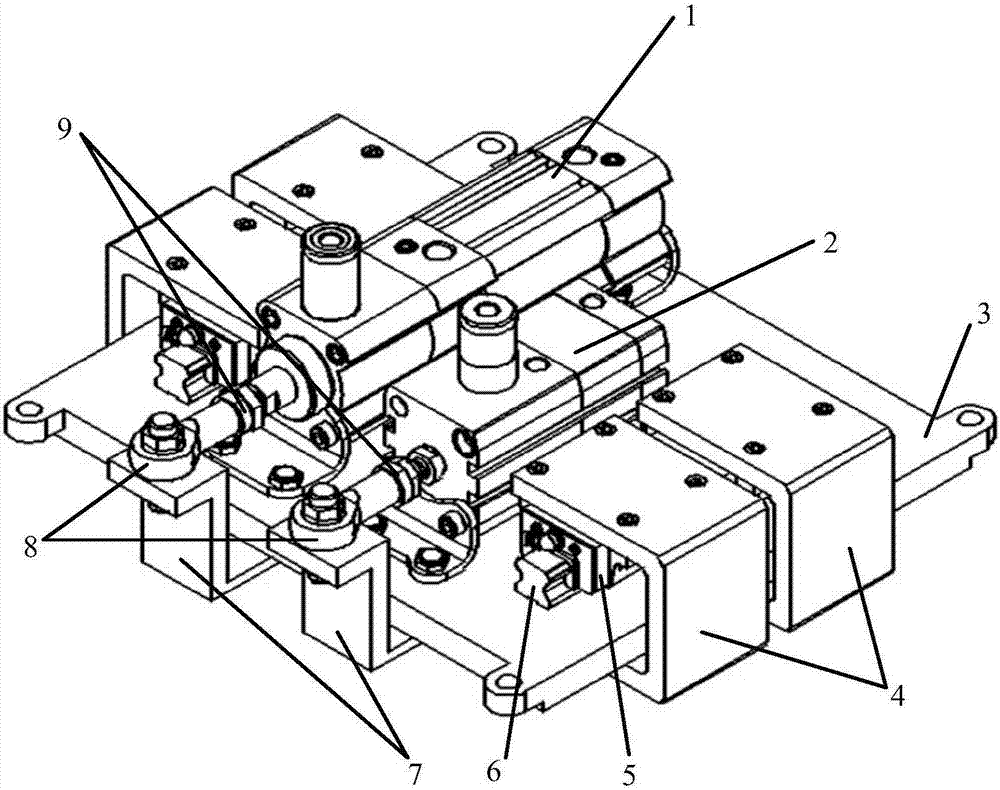

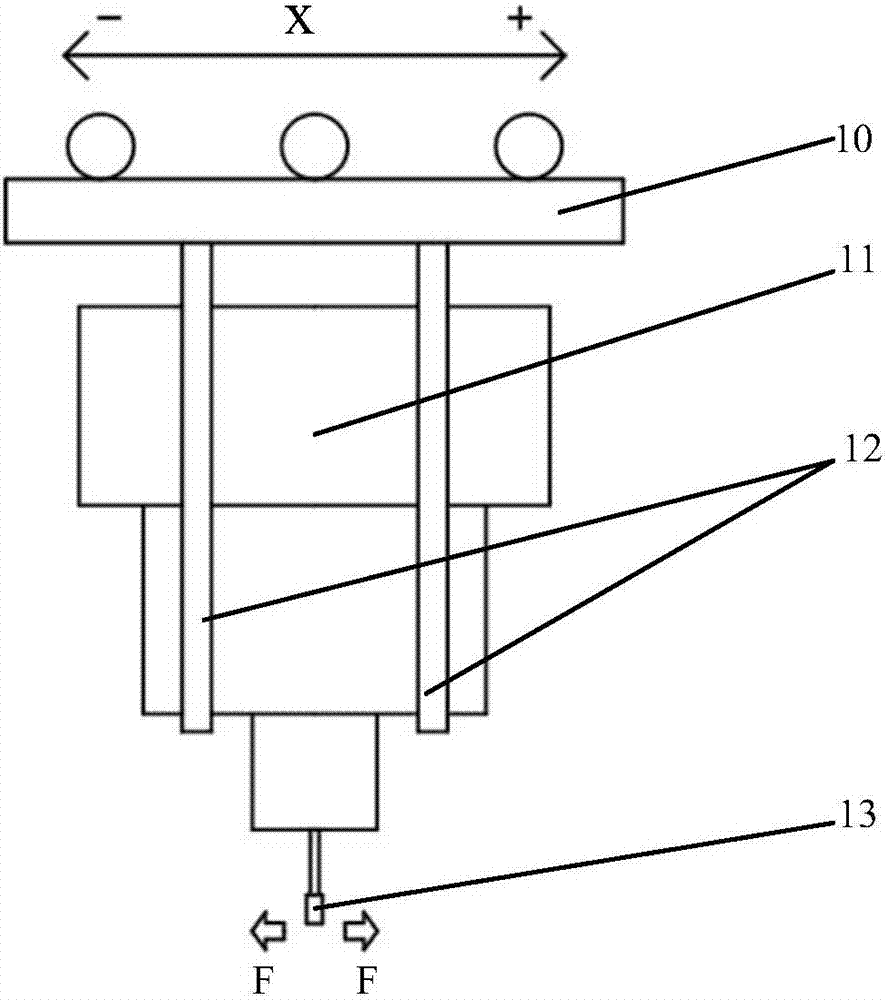

[0018] figure 1 The structure of the flexible grinding constant force control device driven by double actuators of the present invention is given. It includes a bottom plate 3, a linear guide rail 6, a main adjustment cylinder 1, a fine adjustment cylinder 2 and a joint bearing 8. The bottom plate 3 is the base body, and the plate surface is processed with different hole shapes according to requirements, which are used for positioning and installation of components such as cylinders and linear guide rails. The main adjustment cylinder 1 and the fine adjustment cylinder 2 are installed side by side in the middle of the bottom plate 3. Considering the space problem, the cylinder is preferably "single outlet type", the cylinder body is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com