Gilding press for tipping paper

A paper bronzing machine and bronzing roller technology, applied in printing presses, rotary printing machines, printing and other directions, can solve the problems of inconvenient adjustment and inaccuracy, and achieve the effects of convenient operation, easy left and right adjustment, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

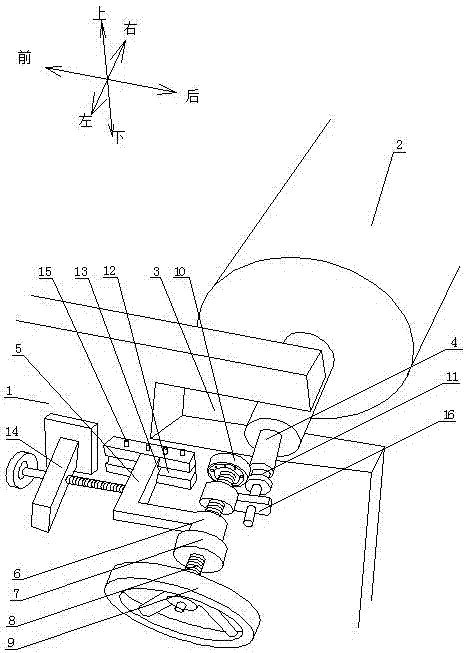

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, a tipping paper hot stamping machine includes a frame 1, a coiling roll and a hot stamping roll 2 are installed on the frame, a shaft head slot 3 for placing the hot stamping roll is arranged on the frame, and the side of the hot stamping roll has a shaft Head 4, the shaft head of the bronzing roller can be slid left and right and installed in the shaft head slot 3, and its characteristics are:

[0018] Install a bracket 5 on the frame, install a nut seat 6 on the bracket, there is a nut 7 on the nut seat, and a screw 8 is installed in the nut, the center line of the screw is parallel to the center line of the bronzing roller, and the outer end of the screw is a hand wheel 9. An adjustment disc 10 is installed at the inner end of the screw;

[0019] The end of the shaft head of the bronzing roller has a limit card groove 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com