Lift slideway

A technology of lifting slides and lifting forks, which is applied in the direction of vehicles with wheels, etc., can solve the problems of inconvenient adding lubricant, large resistance, unfavorable safety, etc., and achieve the effect of fast automatic loading and unloading, reducing moving resistance, and convenient advance and retreat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

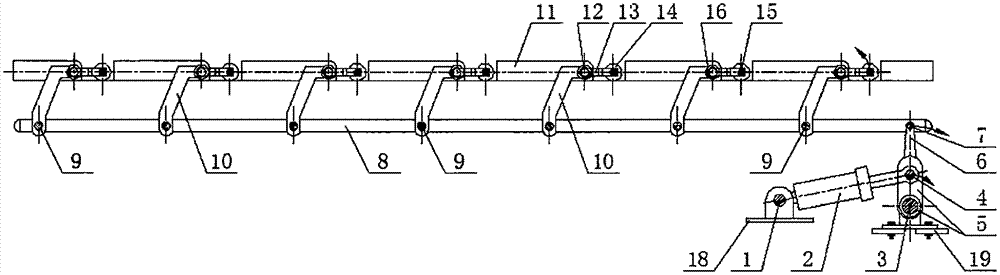

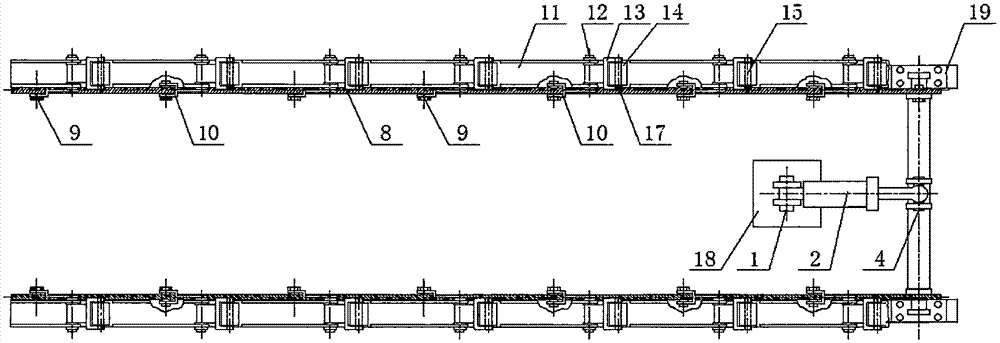

[0018] Figure 1 ~ Figure 2 It is a preferred mode of the present invention, which shows that the lifting slideway is mainly composed of hydraulic cylinders, lifting crank arms, lifting connecting rods, slideway housings, connecting rod crank arms, lifting forks, lifting rollers and various rotating shafts, and is characterized in that : In this structure, three components such as the hydraulic cylinder fixed shaft seat 18, the crank arm fixed shaft seat 19 and the slideway housing 11 are fixed on the chassis of the truck, and the hydraulic cylinder fixed shaft seat 18 and the crank arm fixed shaft seat 19 are located at the bottom of the front end of the truck , the height is lower than the truck girder, and the slideway shell 11 is located on the load-bearing mass. The fixed shaft 1 of the hydraulic cylinder is fixed on its shaft seat 18, and the oil cylinder 2 that controls the lifting slideway can rotate around its fixed shaft 1 during work; 1. The crank arm shaft 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com