An ultra-deep shaft hoist and hoisting method

A technology for hoists and vertical shafts, which is applied to lifting equipment, transportation and packaging in mines. It can solve the problems of lowering lifting efficiency, increasing lifting risks, and increasing the weight of steel wire ropes, so as to improve service life, reduce lifting risks, and increase The effect of greatly improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

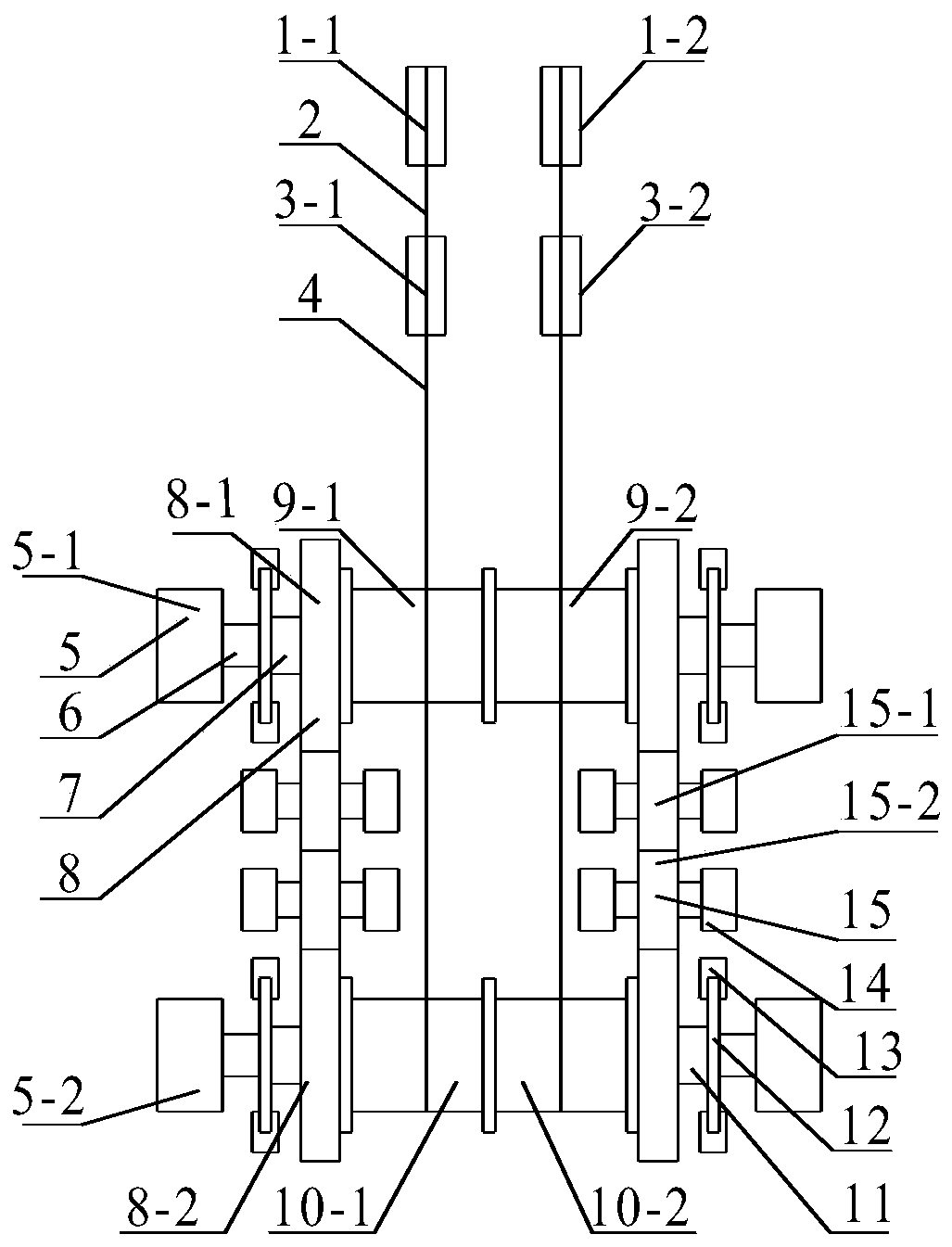

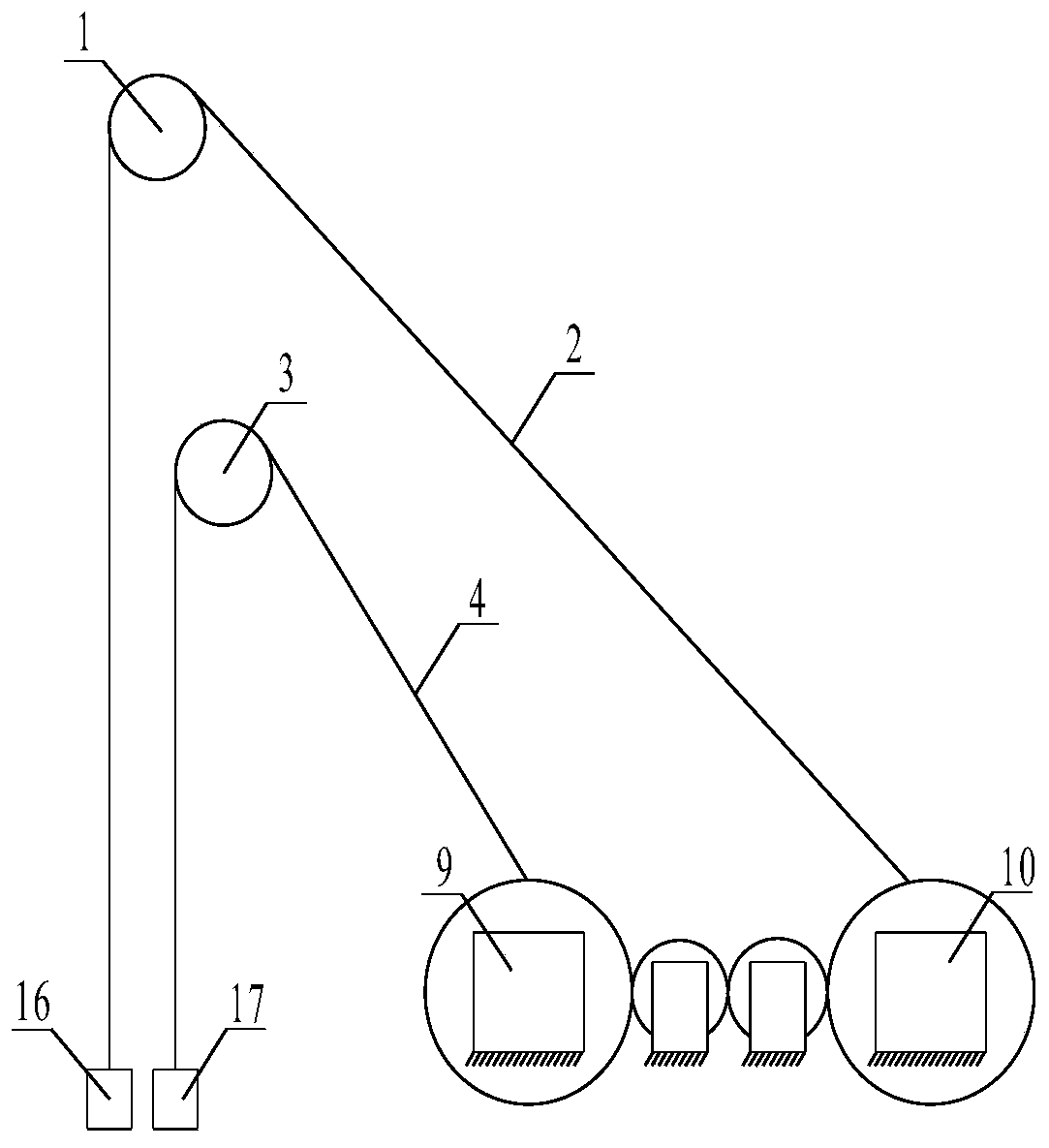

[0025] Example 1, such as figure 1 As shown, the ultra-deep vertical shaft hoist of the present invention includes a sky wheel set above the wellhead and a driving device. The driving device controls the wire rope that bypasses the sky wheel and is connected to the lifting container. The sky wheel set includes the upper sky wheel set 1 And the lower wheel set 3; the driving device includes a symmetrically arranged driving motor 5, a front shaft 7, a rear shaft 11, a front roller 9 and a rear roller 10. The front and rear rollers are respectively installed on the front and rear shafts. The left and right ends of the two shafts are respectively provided with a brake disc 12 and a driving motor 5 in sequence; the front shaft 7 and the rear shaft 11 of the driving motor 5 are connected to the output shaft of the driving motor 5 through a coupling 6 respectively. For the left and right driving motors 5 of the front and rear shafts, the steering of the front motor 5-1 connected on bot...

Embodiment 2

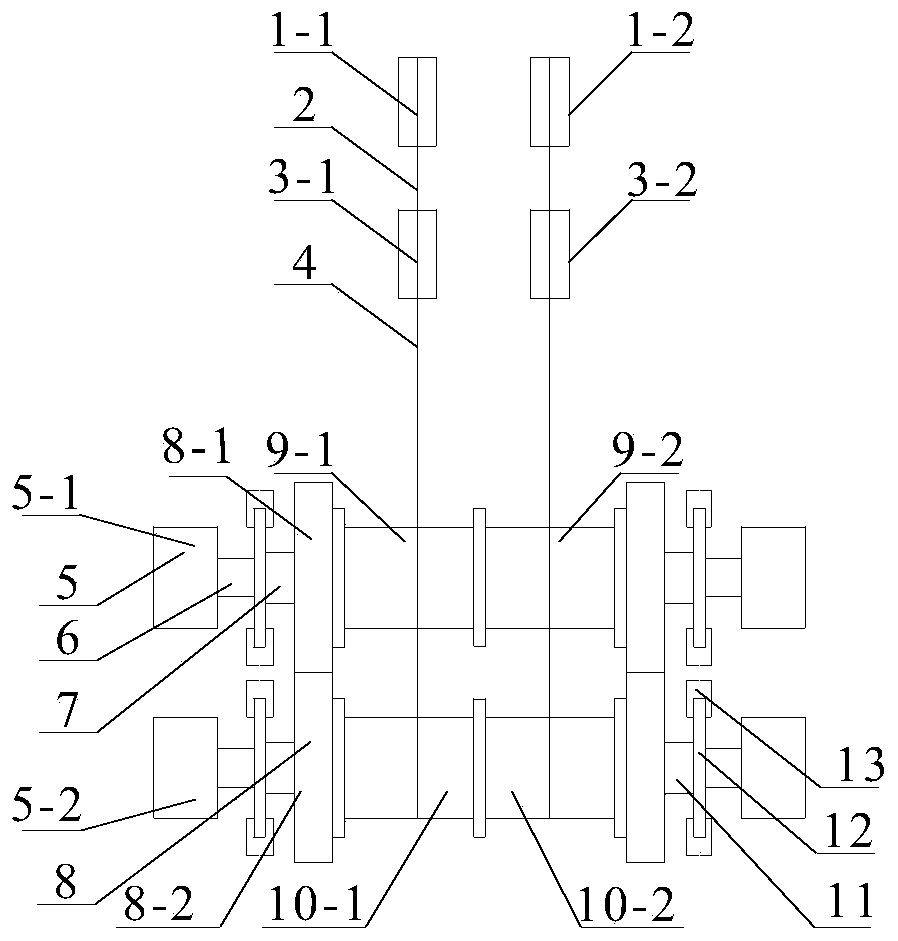

[0028] Example 2, such as image 3 , 4 As shown, it is basically the same as Embodiment 1, and the similarities are omitted. Difference: The number of idlers is 0. The front gear 8-1 and the rear gear 8-2 on the left and right sides of the hoist mesh with each other. When the front wire rope 2 is lifted, the driving motor 5-2 on the rear side rotates clockwise; the rotation direction of the driving motor 5-1 on the front side is opposite to the rotation direction of the rear motor 5-2, which is counterclockwise. When the rear wire rope 4 is lifted, the driving motor 5-1 on the front side rotates clockwise; the rotation direction of the rear motor 5-2 is opposite to the rotation direction of the front motor 5-1, which is counterclockwise.

Embodiment 3

[0029] Example 3, such as Figure 5 , 6 As shown, it is basically the same as in Example 1, and the similarities are omitted. Difference: The number of idlers is 1. The front gear 8-1 and the rear gear 8-2 on the left and right sides of the hoist mesh with an idler gear. The rotation directions of the front and rear driving motors 5-1 and 5-2 are the same, that is: when the front wire rope 2 is lifted, the rear driving motor 5-2 rotates clockwise; the front driving motor 5-1 rotates in the same direction as The direction of rotation of the rear motor 5-2 is the same, clockwise. When the rear wire rope 4 is lifted, the front drive motor 5-1 rotates clockwise; the rotation direction of the rear motor 5-2 is the same as the rotation direction of the front motor 5-1, which is clockwise. The direction of the front and rear steel wire ropes on the drum is exactly opposite, one is the upper rope and the other is the lower rope.

[0030] The lifting method of the ultra-deep vertical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com