A kind of synthetic method of photoinitiator isopropyl thioxanthone

A technology for isopropyl thioxanthone and crude isopropyl thioxanthone, which is applied in organic chemistry and other fields, can solve the problems of high cost of raw materials, harsh reaction conditions, and low inhibition yield, and achieve less waste, The effect of stable quality control and high conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

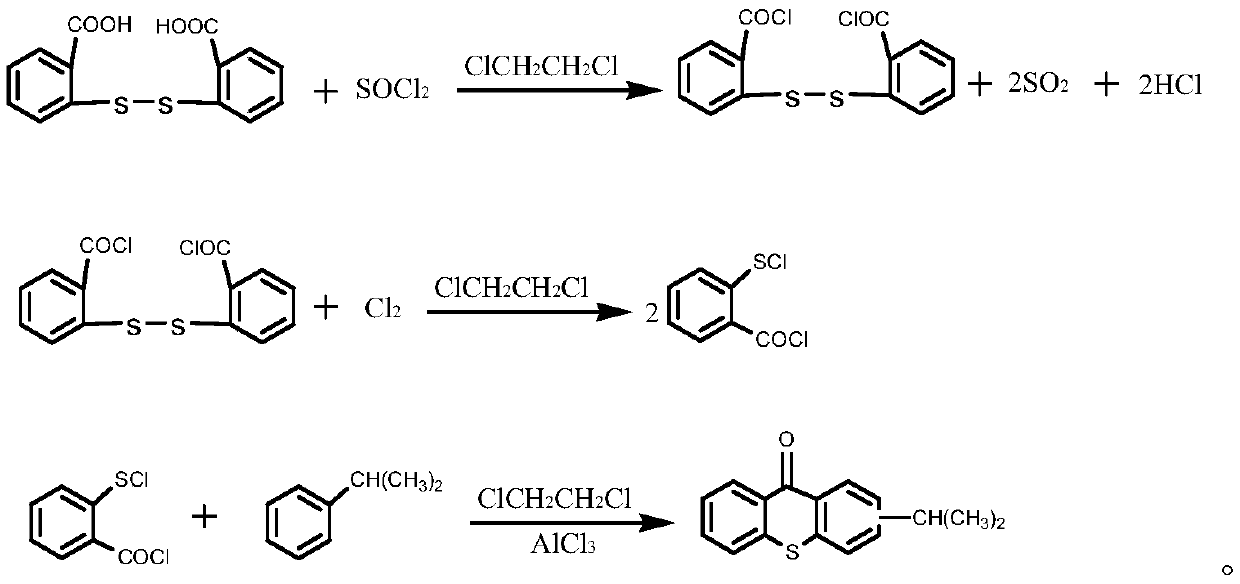

Method used

Image

Examples

Embodiment 1

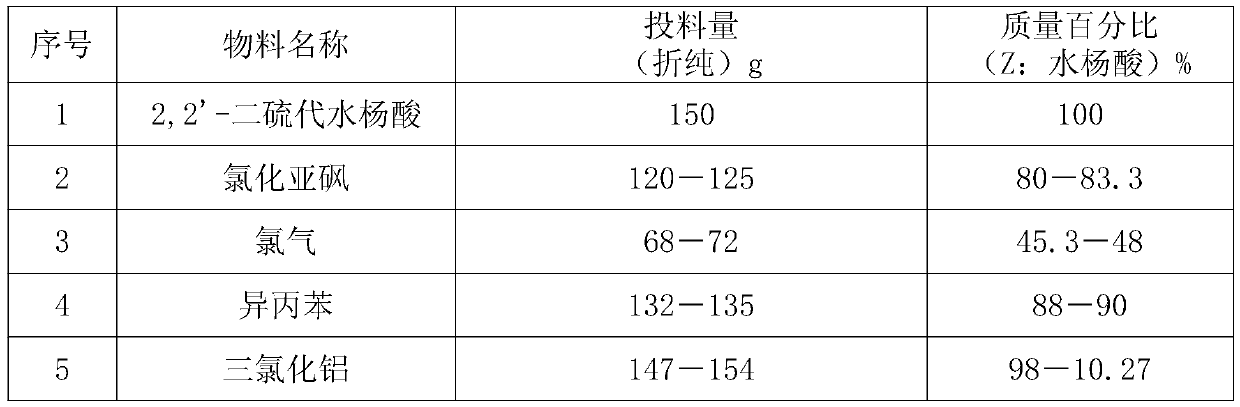

[0023] The specific steps of the synthesis method are as follows: primary chlorination: add 1000 ml of dichloroethane, 2,2'-dithiodibenzoic acid dithio 150g of salicylic acid, add 125g of thionyl chloride dropwise at 65-70°C, drop it for about 2-2.5 hours, then keep it warm at 70-75°C for 1 hour, sample and analyze, the raw material dithiosalicylic acid disappears, The reaction is completed; secondary chlorination: after the one-step chlorination reaction is qualified, the temperature is lowered to 10-15°C, and about 72g of chlorine gas is passed into the reaction liquid at a rate of 20-25g / h, Insulate the reaction for 0.5h, take a sample to judge the end point of the reaction, if it is qualified, stop the chlorine flow; Friedel-Crafts: After the chlorine flow is completed, lower the temperature to below 10°C, control the temperature at 7-10°C and add 154g of anhydrous aluminum trichloride in batches, and drop it at the same time Add 135 g of cumene, add 9 g of cumene dropwise...

Embodiment 2

[0025] The specific steps of the synthesis method are as follows: primary chlorination: add 1000 ml of dichloroethane, 2,2'-dithiodibenzoic acid dithio For 150g of salicylic acid, add 120g of thionyl chloride dropwise at 65-70°C, drop it for about 2-2.5 hours, then keep it warm at 70-75°C for 1 hour, sample and analyze, the raw material dithiosalicylic acid disappears, The reaction is completed; secondary chlorination: after the one-step chlorination reaction is qualified, the temperature is lowered to 10-15°C, and about 68 chlorine gas is introduced into the reaction liquid at a rate of 20-25g / h, Heat preservation reaction for 0.5h, take a sample to judge the end point of the reaction, if it is unqualified, prolong the heat preservation time for 0.5h, then take a sample for analysis, if it is qualified, stop the chlorine flow; Friedel-Crafts: After the chlorine flow is completed, cool down to below 10°C, and control the temperature at 7-10°C Add 147g of anhydrous aluminum tri...

Embodiment 3

[0027] The specific steps of the synthesis method are as follows: primary chlorination: add 1000 ml of dichloroethane, 2,2'-dithiodibenzoic acid dithio For 150g of salicylic acid, add 120g of thionyl chloride dropwise at 65-70°C, drop it for about 2-2.5 hours, then keep it warm at 70-75°C for 1 hour, sample and analyze, the raw material dithiosalicylic acid disappears, The reaction is completed; secondary chlorination: after the one-step chlorination reaction is qualified, the temperature is lowered to 10-15°C, and about 72g of chlorine gas is passed into the reaction liquid at a rate of 20-25g / h, Heat preservation reaction for 0.5h, take a sample to judge the end point of the reaction, if it is unqualified, prolong the heat preservation time for 0.5h, then take a sample for analysis, if it is qualified, stop the chlorine flow; Friedel-Crafts: After the chlorine flow is completed, cool down to below 10°C, and control the temperature at 7-10°C Add 154g of anhydrous aluminum tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com