Adjustable arc gate leaf large-piece assembly device and assembly method thereof

An adjustable door leaf technology, applied in marine engineering, construction, barrage/weir, etc., can solve the problems of heavy workload, complex process, large door leaf volume, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

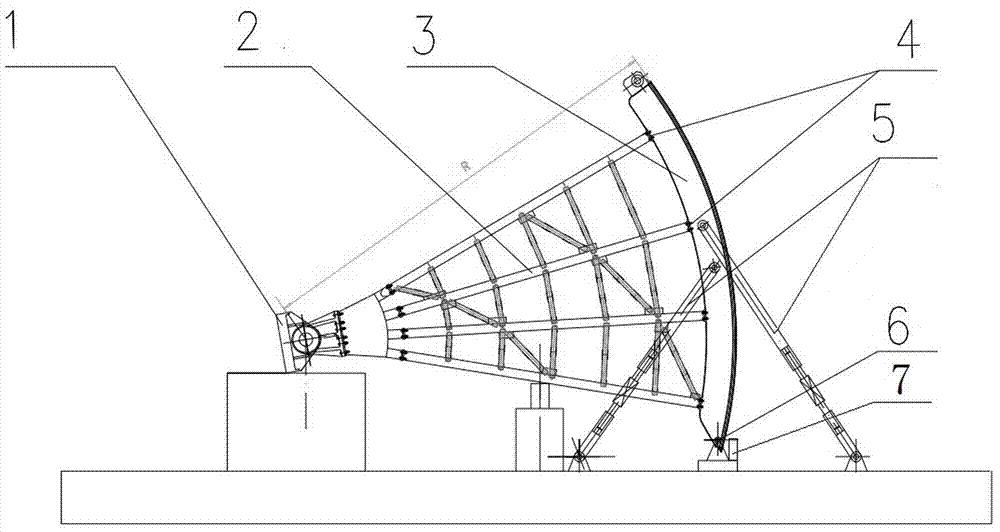

[0028] Such as figure 1 , an adjustable arc door door leaf assembly device, including a hinge seat 1, a door leaf support 6 and a door leaf adjustment rod 5; the hinge seat 1 is used to hinge the end of the arc door support arm 2, and the door leaf 3 is erected in the device, and the door leaf support 6 is used to hinge the bottom of the door leaf 3; one end of the door leaf adjusting rod 5 is hinged to the middle of the door leaf 3, and the other end is hinged to a fixed support.

[0029]This is one of the most basic embodiments of the present invention. After the position of the hinge seat 1 is set, install the support arm 2 in sequence according to the tooling, and set the door leaf support 6 at a suitable position to fit the radius of the door leaf 3. The bottom of the door leaf 3 is hinged on the door leaf support 6 and passes through the door leaf. Adjustment rod 5 is driven to realize clockwise and / or counterclockwise angle adjustment, so as to complete the alignment w...

Embodiment 2

[0031] Such as figure 1 , an adjustable arc door door leaf assembly device, including a hinge seat 1, a door leaf support 6 and a door leaf adjustment rod 5; the hinge seat 1 is used to hinge the end of the arc door support arm 2, and the door leaf 3 is erected in the device, and the door leaf support 6 is used to hinge the bottom of the door leaf 3; one end of the door leaf adjusting rod 5 is hinged to the middle of the door leaf 3, and the other end is hinged to a fixed support.

[0032] Both the hinge seat 1 and the door leaf support 6 include a platform body, the platform body of the hinge seat 1 is higher than the platform body of the door leaf support 6, and the door leaf support 6 is provided with a limit block 7, the limit The block 7 is arranged outside the hinge point between the door leaf 3 and the door leaf support 6 to limit the adjustment angle of the door leaf 3 .

[0033] This is a preferred embodiment of the invention. After the position of the hinge seat 1 ...

Embodiment 3

[0035] Such as figure 1 , a method for assembling an adjustable arc door door leaf assembling device, comprising the following steps:

[0036] Steps for determining the position of the door leaf support: select the position of the hinge seat 1, install the arc door support arm 2 on the support hinge seat 1, and select the door leaf support 6 through the arc door support arm 2 installed on the hinge seat 1 The fixed position is selected on both sides of the door leaf support 6 as a fixed point for hinged door leaf adjustment rod 5 and one end of the door leaf adjustment rod 5 is hinged on the fixed point;

[0037] Determination of the turning radius of the door leaf and installation steps: Determine the turning radius R according to the selected position of the hinge seat 1 and the fixed position of the door leaf support 6, erect the door leaf 3, and hinge the door leaf 3 with a straight side as the bottom edge on the door on the leaf support 6, and hinge the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com