Control method, device and TCU for synchronizer pre-engagement under sliding and downshift working condition

A control method and control device technology, which is applied in the direction of transmission control, clutch, and components with teeth, etc., to achieve the effect of avoiding different effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] At present, the synchronizer of the DCT vehicle can make the gears to be meshed reach a consistent speed for smooth meshing and shifting. However, when the speed difference between the two ends of the synchronizer is large, especially in the case of coasting downshifts, there is often the problem that the speed synchronization stage is difficult to control, resulting in gear-in noise. If the pre-engagement is performed as soon as the clutch interaction control is completed in the downshift condition, there will be synchronizers on the odd and even axles when the vehicle is running stably, resulting in high DCT fuel consumption.

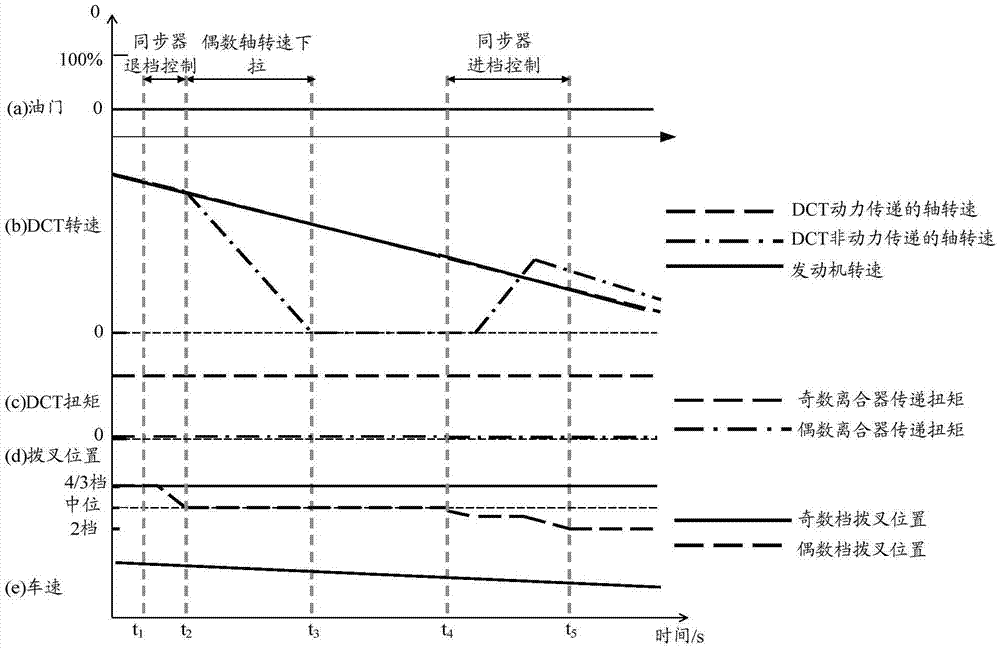

[0044] In order to make those skilled in the art better understand the above-mentioned problems, figure 1 A schematic diagram of the downshifting process from the 4th gear down to the 2nd gear in the prior art is shown.

[0045] figure 1 (a) is a curve diagram of the throttle signal change; figure 1 (b) is the DCT rotational speed change cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com