Split kindergarten water boiler

A kind of technology for kindergartens and water boilers, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of difficulty in meeting children's collective drinking water needs, few water outlets, electric shock hazards, etc., and achieve convenient centralized management and maintenance, small water system power, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

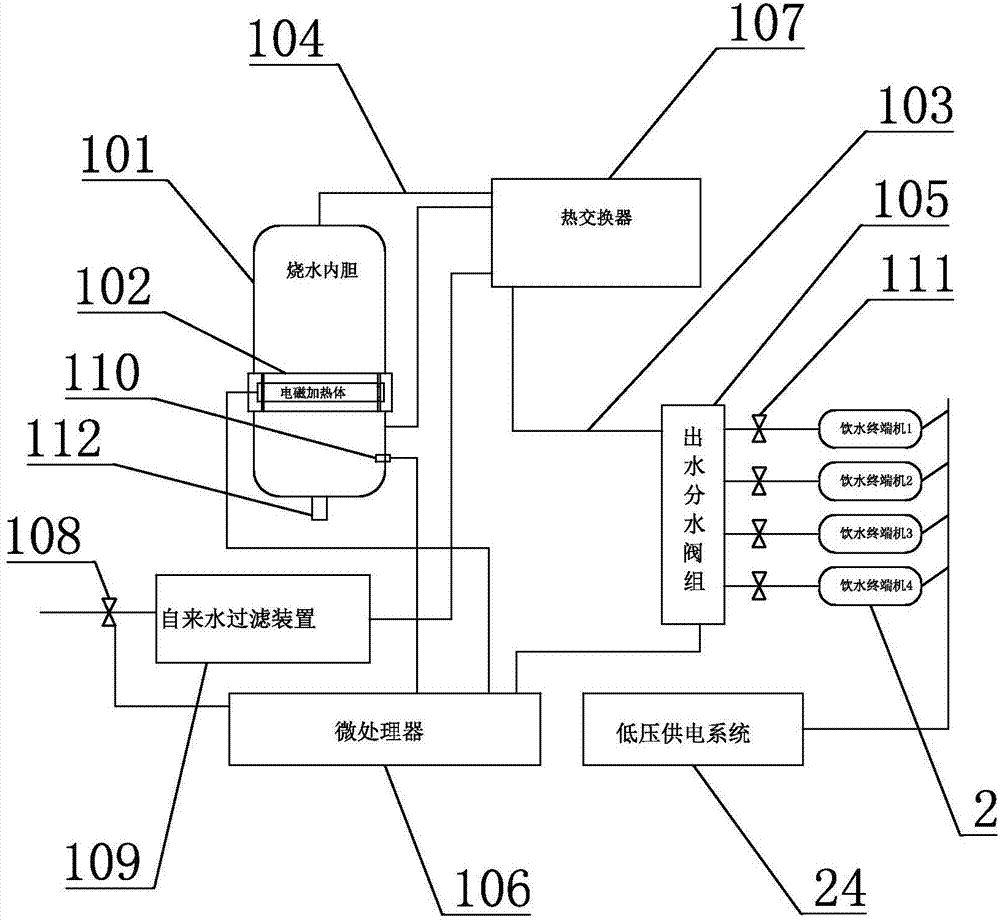

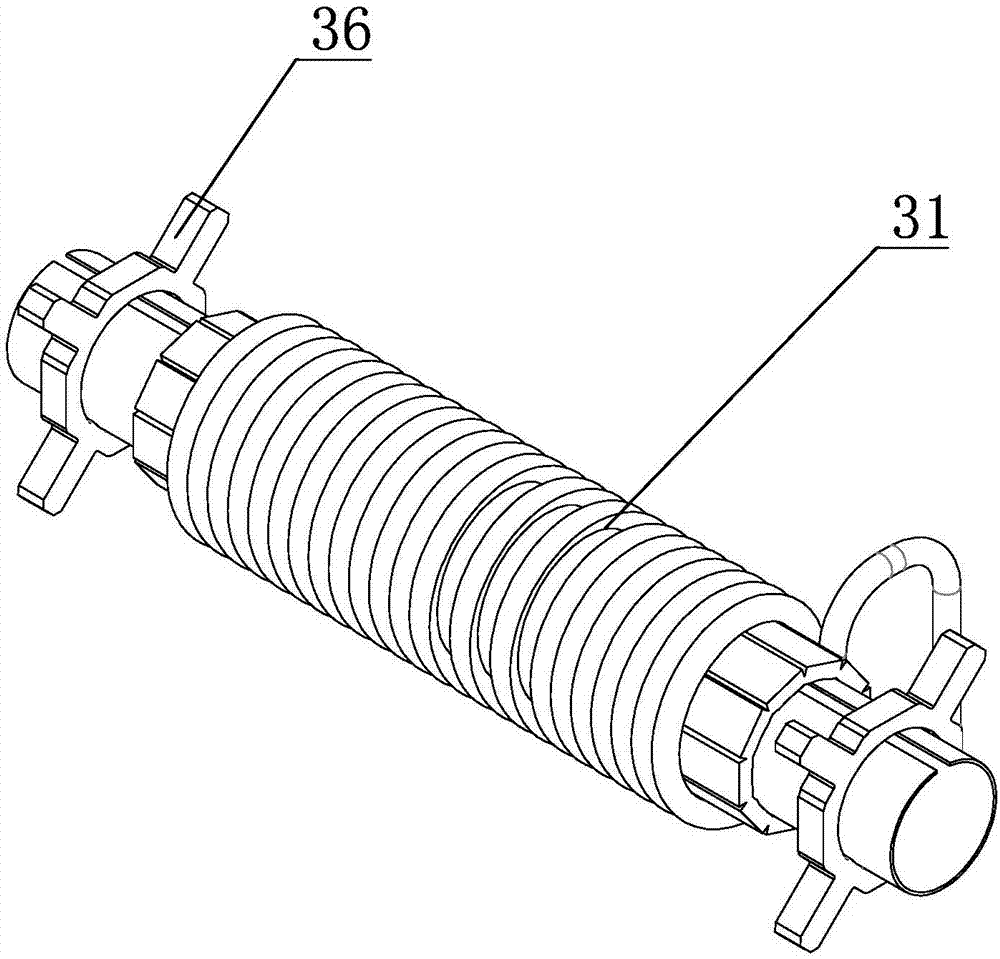

[0022] refer to Figures 1 to 4 , a split type kindergarten water boiler, including a water maker 1 and a drinking water terminal 2, the water maker 1 is suspended and installed at a high place, and the drinking water terminal 2 is installed at a low place where children can reach, so as to facilitate water collection. The water making machine 1 is provided with a water-boiling liner 101 and a microprocessor 106. The middle part of the water-boiling liner 101 is provided with a stainless steel tube 102 horizontally placed and running through it. The stainless steel tube 102 is equipped with a tubular electromagnetic The heating body 3, the electromagnetic heating body 3 includes a coil winding core tube 31 with an axial gap along one side, and the coil winding core tube 31 is sequentially pasted with two layers of mica sheets 32 and a layer of iron from the inside to the outside. An oxygen magnetic strip 33, the ferrite magnetic strip 33 is covered with an insulating heat-shri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com