Polyethylene spiral corrugated pipe reinforced by steel strip and process for manufacturing polyethylene spiral corrugated pipe

A technology of polyethylene spiral and bellows, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., which can solve the problems of inconvenient transportation and laying, easy damage, poor low-temperature impact performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

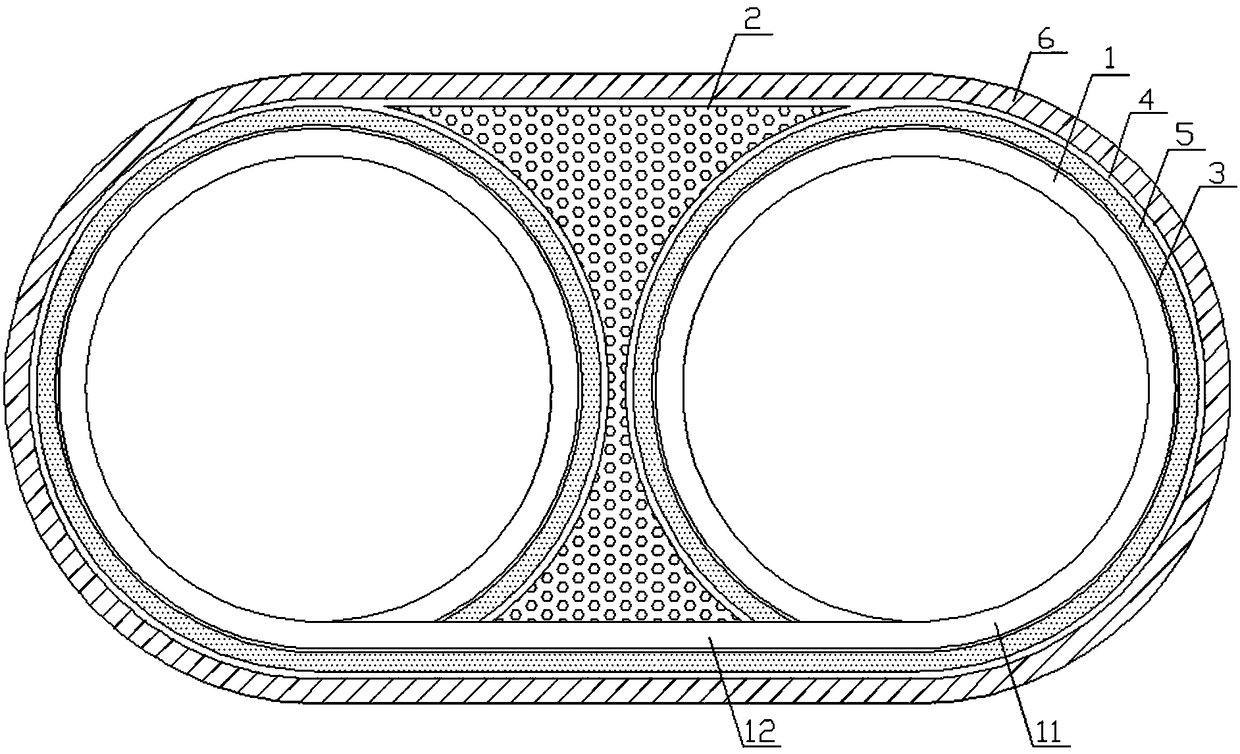

[0025] The present invention provides such figure 1 The shown steel belt reinforced polyethylene spiral corrugated pipe includes a pipe body 1, the pipe body 1 includes two circular plates 11 and a straight plate 12, and the two circular plates 11 and a straight plate 12 are integrated Forming is conducive to convenient processing and good sealing performance. Two circular plates 11 are arranged on both sides of a straight plate 12, and a sound-absorbing reinforcement layer 2 is provided between the two circular plates 11. The sound-absorbing reinforcement layer 2 It is made by mixing waste plastic granules and epoxy resin glue, which saves resources, utilizes waste, and is environmentally friendly, and the granulated waste plastic can be porous, which can absorb sound and reduce noise. The outer wall of the pipe body 1 is provided with tensile reinforcement Layer 3, the tensile reinforcement layer 3 is made of nano boron fiber material, the nano boron fiber material has high ...

Embodiment 2

[0036] The present invention provides such figure 1 The shown steel belt reinforced polyethylene spiral corrugated pipe includes a pipe body 1, the pipe body 1 includes two circular plates 11 and a straight plate 12, and the two circular plates 11 and a straight plate 12 are integrated Forming is conducive to convenient processing and good sealing performance. Two circular plates 11 are arranged on both sides of a straight plate 12, and a sound-absorbing reinforcement layer 2 is provided between the two circular plates 11. The sound-absorbing reinforcement layer 2 It is made by mixing waste plastic granules and epoxy resin glue, which saves resources, utilizes waste, and is environmentally friendly, and the granulated waste plastic can be porous, which can absorb sound and reduce noise. The outer wall of the pipe body 1 is provided with tensile reinforcement Layer 3, the tensile reinforcement layer 3 is made of nano boron fiber material, the nano boron fiber material has high ...

Embodiment 3

[0047] The present invention provides such figure 1 The shown steel belt reinforced polyethylene spiral corrugated pipe includes a pipe body 1, the pipe body 1 includes two circular plates 11 and a straight plate 12, and the two circular plates 11 and a straight plate 12 are integrated Forming is conducive to convenient processing and good sealing performance. Two circular plates 11 are arranged on both sides of a straight plate 12, and a sound-absorbing reinforcement layer 2 is provided between the two circular plates 11. The sound-absorbing reinforcement layer 2 It is made by mixing waste plastic granules and epoxy resin glue, which saves resources, utilizes waste, and is environmentally friendly, and the granulated waste plastic can be porous, which can absorb sound and reduce noise. The outer wall of the pipe body 1 is provided with tensile reinforcement Layer 3, the tensile reinforcement layer 3 is made of nano boron fiber material, the nano boron fiber material has high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com