An intelligent steel strand end optical fiber joint packaging connector and its installation method

A technology of intelligent steel strands and optical fiber connectors, applied in the direction of instruments, optics, light guides, etc., can solve the problems of loss of manpower and material resources, loss of use value, layout process survival rate and low monitoring range, and achieve economical installation, compact structure, The effect of ensuring the survival rate of encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

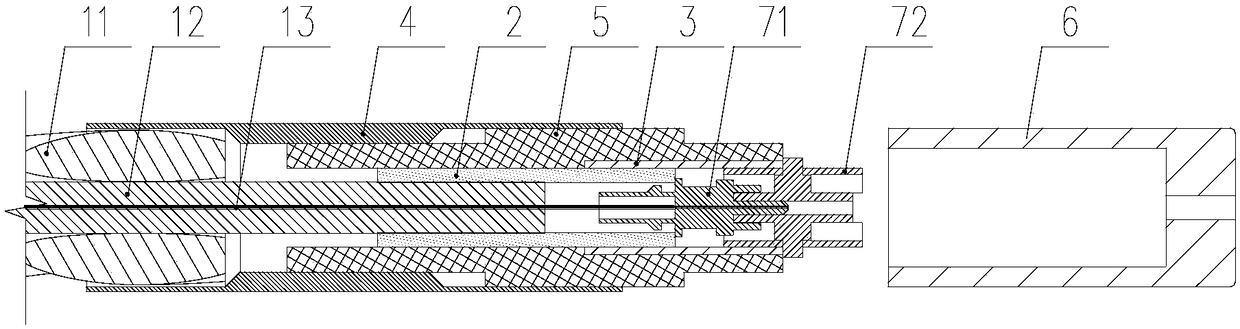

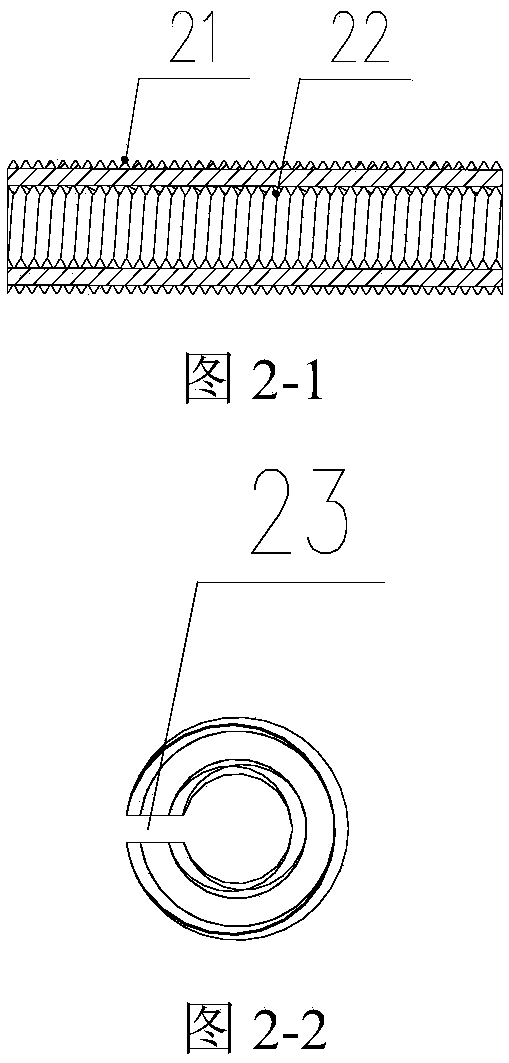

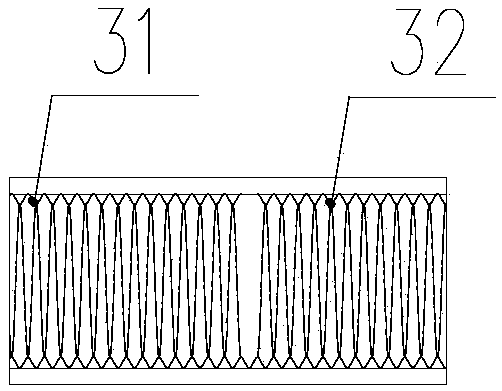

[0047] Such as Figure 1-7 As shown, a smart steel strand end optical fiber joint packaging connector includes a connecting inner cylinder 2, a flange connection sleeve 3 and a connecting outer cylinder, and the connecting inner cylinder 2 is a smart steel strand center wire 12, such as Figure 7 As shown, the central wire 12 of the intelligent steel strand is embedded with a fiber grating sensor 13 in the axial groove 14, and the 3 sets of flange connection sleeves pass through the first internal thread 31 of the flange connection sleeve at both ends and the second flange connection sleeve. The inner thread 32 is connected to the inner cylinder 2 and the optical fiber flange joint 72, and one side of the inner cylinder 2 is connected to the central wire 12 of the smart steel strand by connecting the inner cylinder inner thread 22, and the optical fiber flange joint 72 is located outside the optical fiber jumper joint 71. Protect the optical fiber jumper connector 71;

[0048...

experiment example

[0070] In order to highlight the effect of the fiber optic connector at the end of the smart steel strand to encapsulate the connector, the group of connectors packaged with the fiber optic connector at the end of the smart steel strand is named group A, and the unused fiber optic smart strand is named group B Conduct a comparative experiment to observe the loss during transportation and the loss during use, see Table 1 for details:

[0071] As can be seen from Table 1, after two years of use of the intelligent steel strand without using the optical fiber joint at the end of the intelligent steel strand to encapsulate the connector, the loss rate is as high as 88%, while the intelligent steel strand of the present invention The consumption of the terminal optical fiber joint packaging connector is significantly reduced during transportation and use, and the consumption rate is only 7% after two years of use, thereby greatly reducing the cost and improving the survival rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com