Peripheral auxiliary frame sealing adhesive coating device and method

A technology of coating device and sealant, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor display of liquid crystal display panels, uneven cell thickness, etc., and achieve the effect of avoiding poor display and avoiding abnormal detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

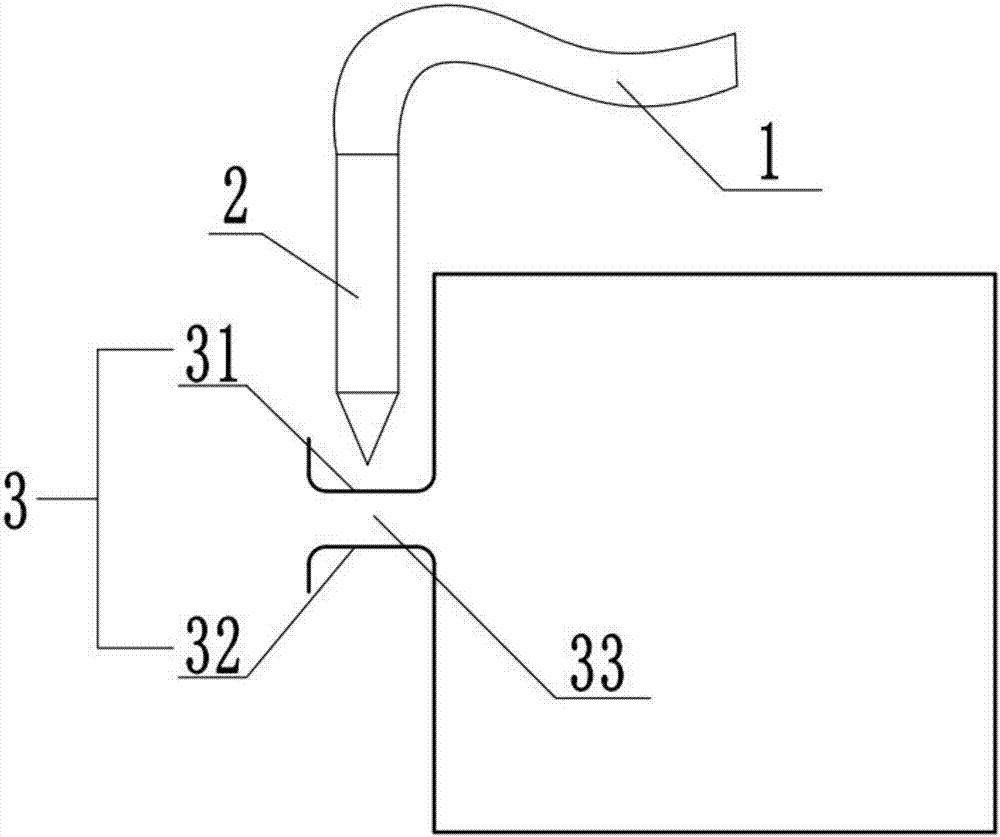

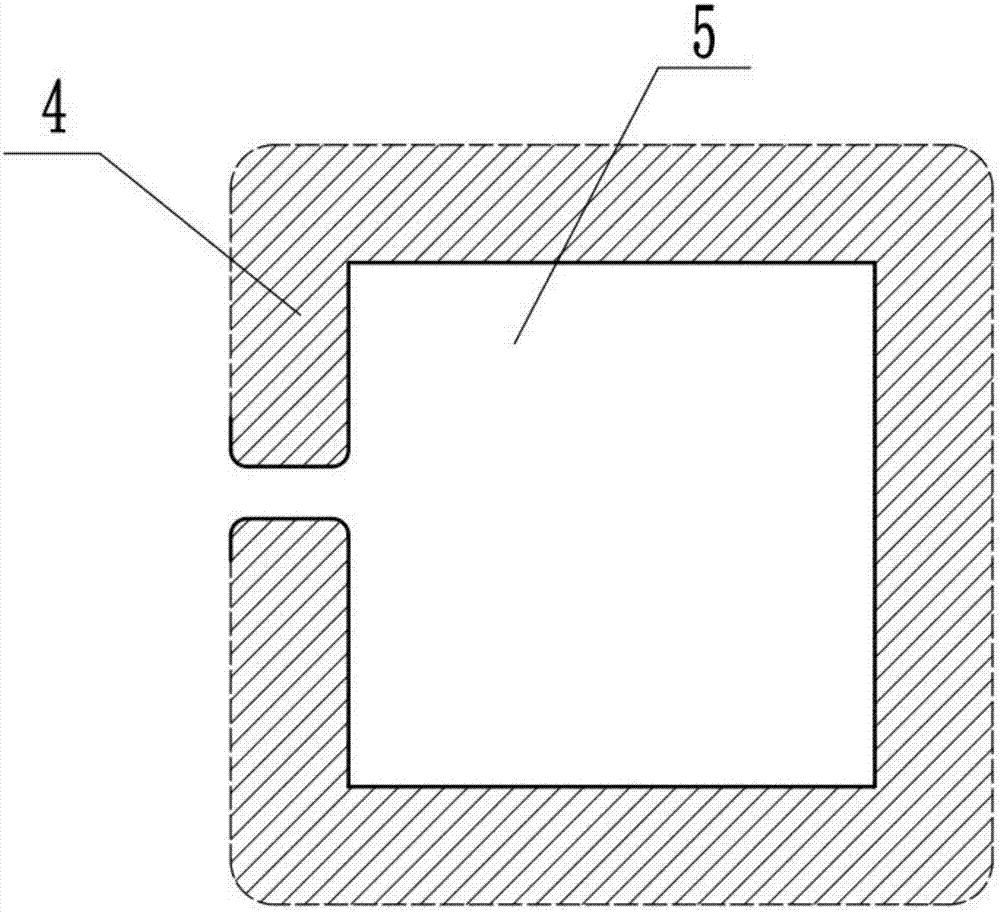

[0031] Such as figure 1 As shown, the present invention provides a peripheral auxiliary frame sealant coating device, which includes: a rubber tube 1 with a built-in frame sealant, a frame sealant needle 2 connected to the rubber tube, and a needle for detecting the frame sealant 2 and The laser sensor for the distance between the substrates 5 also includes a glue-coated guiding structure 3 on one side of the substrate 5 .

[0032] In one embodiment, the gluing guiding structure 3 includes a gluing starting section 31 for starting gluing and a gluing ending section 32 for gluing, and a gap 33 is provided between the starting section 31 and the terminating section 32 .

[0033] Since a gap 33 is provided between the starting section 31 and the ending section 32, coating is started from the starting section 31 until reaching the ending section 32, and the coating is finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com