Electronic anti-theft antenna and bonding and seamless processing method thereof

An electronic anti-theft and processing method technology, applied in antennas, anti-theft alarms, antenna parts and other directions, can solve the problems of easy entry of dust, bending and deformation of acrylic sheets, and limited penetration depth of glue, so as to improve aesthetics and reduce gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

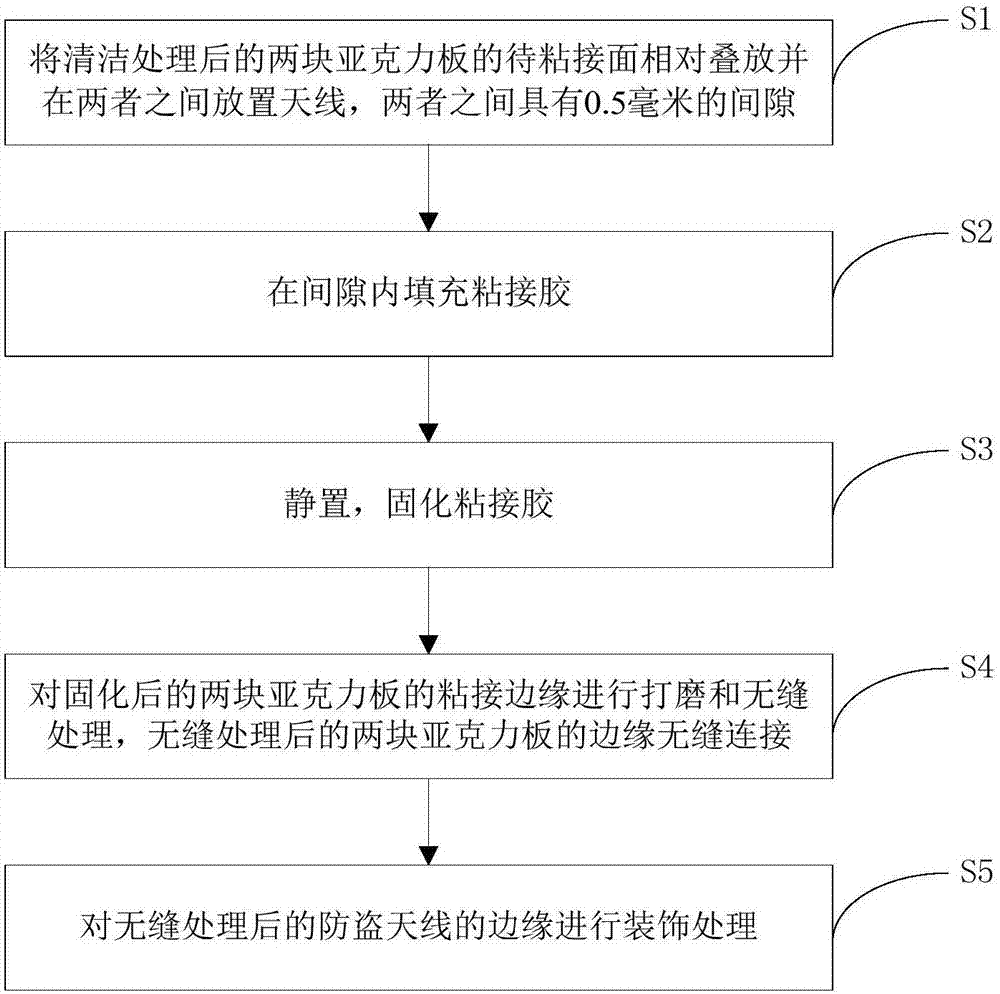

Method used

Image

Examples

Embodiment Construction

[0020] Acrylic is a common name for polymer transparent materials. Its chemical name is polymethyl methacrylate, or PMMA for short. It is mainly a polymer obtained by the polymerization of acrylic acid and its esters. It is the best quality synthetic transparent material so far. of. The use of acrylic boards to make the detection door of the electronic commodity anti-theft system greatly improves the aesthetics of the detection door. In the existing detection door of this kind, the antenna is arranged in two relatively bonded acrylic boards. In the prior art, the bonding of two acrylic plates is achieved through the penetration of glue. Due to the large volume of the detection door, the corresponding area pressure of the acrylic plates is relatively large. In order to have a greater bonding firmness, The penetration gap between the two acrylic panels should be larger. Large penetration gaps not only affect the aesthetics, but also easily allow external impurities such as wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com