Liquid deodorant and preparation method thereof

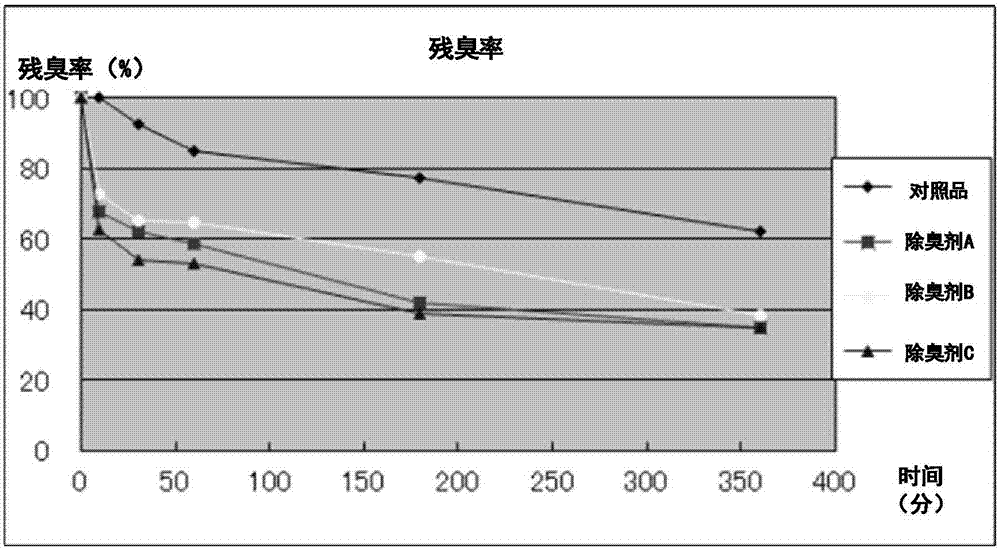

A deodorant and liquid technology, which is applied in the field of liquid deodorant and its preparation, can solve the problems of unsustainable deodorization and slow deodorization speed of deodorant, and achieve long-lasting deodorization performance, fresh and pleasant air, and deodorization. The effect of smelly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

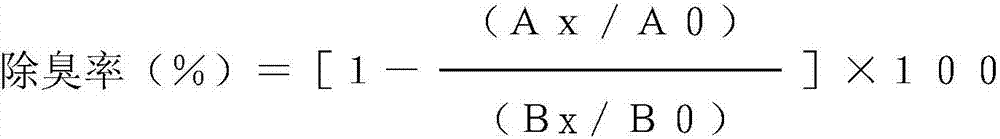

Examples

Embodiment 1

[0031] Liquid deodorant A

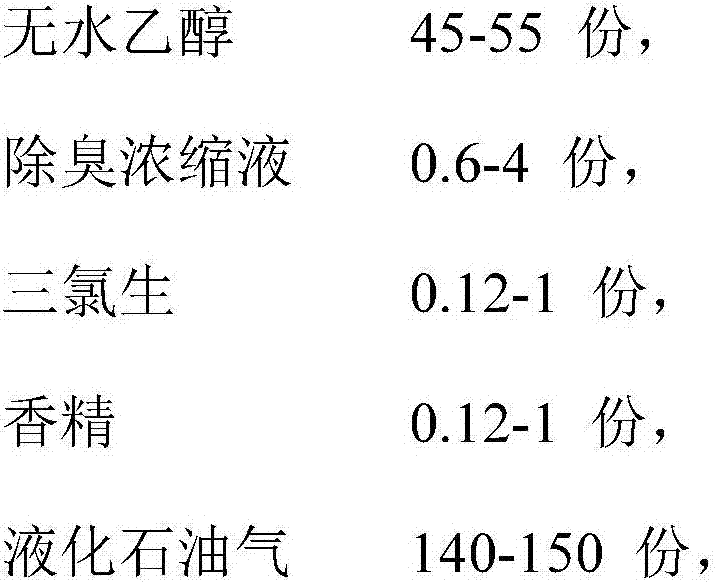

[0032] Liquid deodorant A includes the following components by weight:

[0033] 50 parts of absolute ethanol,

[0034] 2 parts deodorant concentrate,

[0035] 0.6 parts of triclosan,

[0036] 0.6 parts of flavor,

[0037] 145 parts of liquefied petroleum gas.

[0038] Among them, the deodorant concentrate is composed of the following parts by weight: 0.6 parts of dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 0.4 parts of corn extract, 99 parts of water.

[0039] The liquid deodorant A is prepared according to the following preparation method:

[0040] S1: Weigh dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride, corn extract and water according to the above weight parts, and then mix these three evenly to obtain deodorant Concentrate.

[0041] S2: Weigh the absolute ethanol, deodorant concentrate, triclosan and flavor according to the above-mentioned parts by weight, and then sequentially add the deodorant concentrate, triclosan an...

Embodiment 2

[0044] Liquid deodorant B

[0045] Liquid deodorant B includes the following components by weight:

[0046] 45 parts of absolute ethanol,

[0047] 0.6 parts of deodorant concentrate,

[0048] 0.12 parts of triclosan,

[0049] 0.12 parts of flavor,

[0050] 140 parts of liquefied petroleum gas.

[0051] Among them, the deodorant concentrate is composed of the following parts by weight: 0.6 parts of dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 0.4 parts of corn extract, 99 parts of water.

[0052] The preparation method of the liquid deodorant B is the same as the preparation method of the liquid deodorant A.

Embodiment 3

[0054] Liquid deodorant C

[0055] Liquid deodorant C includes the following components by weight:

[0056] 55 parts of absolute ethanol,

[0057] 4 parts deodorant concentrate,

[0058] 1 part of triclosan,

[0059] 1 flavor,

[0060] 150 parts of liquefied petroleum gas.

[0061] Among them, the deodorant concentrate consists of the following components by weight: 0.6 parts of dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 0.4 parts of corn extract, 99 parts of water.

[0062] The preparation method of the liquid deodorant C is the same as the preparation method of the liquid deodorant A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com