Automatic rotary workbench

A technology for rotating workbenches and worktable surfaces, which is applied in the direction of workbenches and manufacturing tools, and can solve the problems of unadjustable workbench speed, long length, and large work area occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0012] The present invention will be described in detail below with reference to the accompanying drawings and examples.

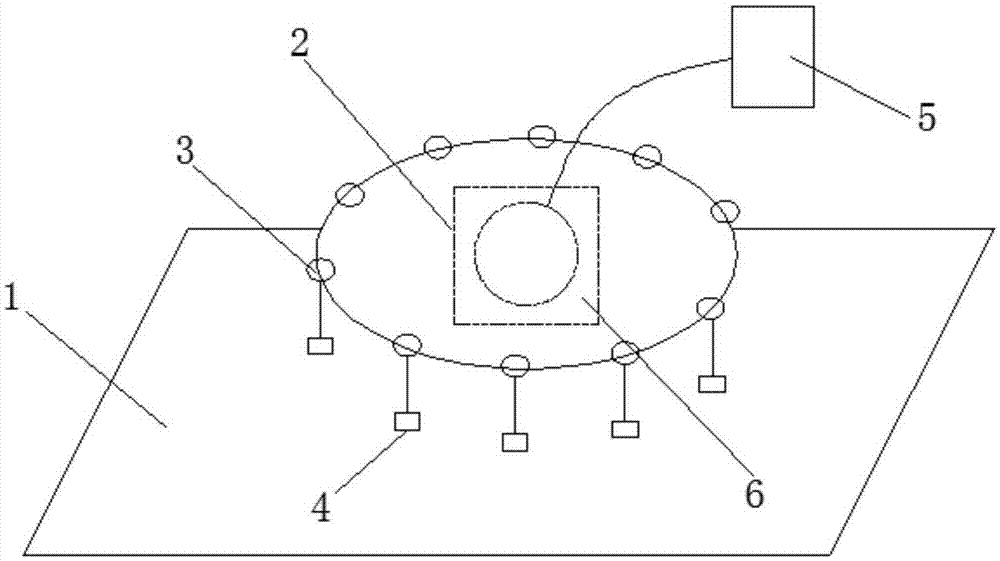

[0013] Such as figure 1 A kind of automatic control rotary workbench shown, comprises work support 2 and work surface 1, and described work support 2 is fixedly arranged on the work surface 1, and described work support 2 is internally provided with and its motor 6, and described motor 6 drives The working support 2 rotates, the motor 6 is connected with the controller 5, and the motor 6 is electrically connected with the controller 5; the working support 2 is provided with a suspension hook 3, and the suspension hook 3 is fixedly provided with a hoisting piece 4 .

[0014] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com