A thermal spray composite powder and its preparation method and application

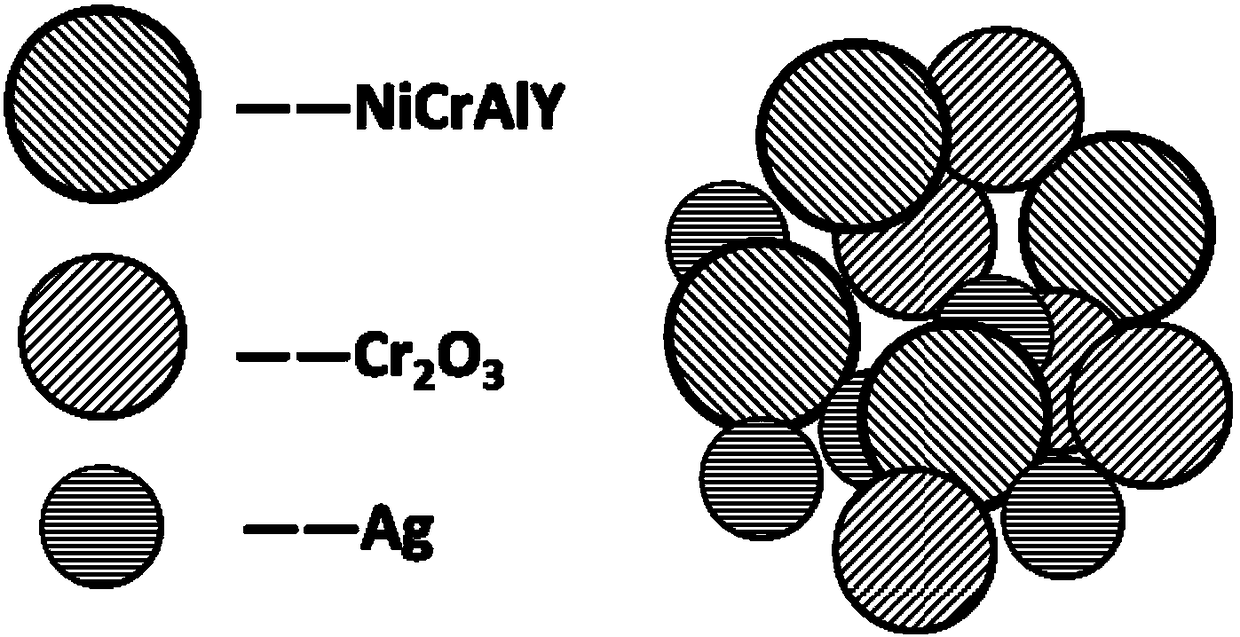

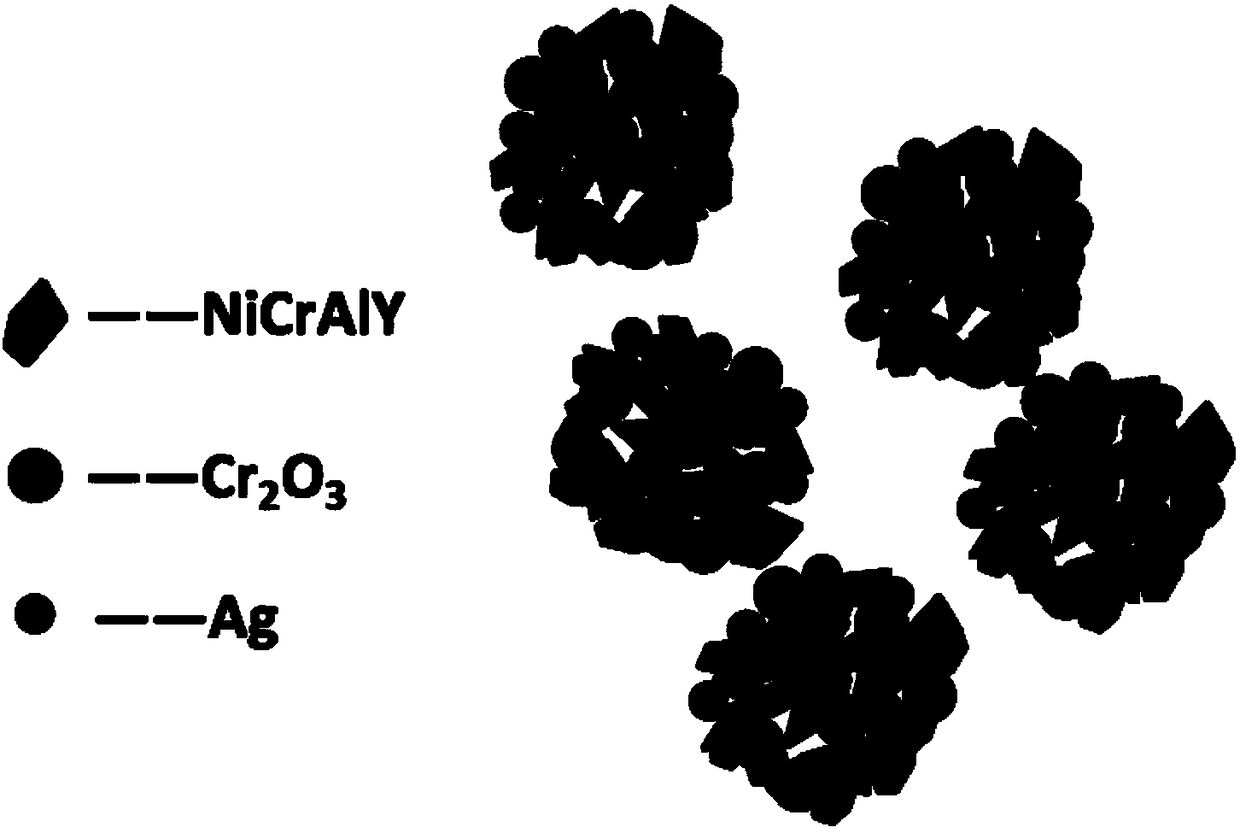

A composite powder, thermal spraying technology, applied in the direction of coating, fusion spraying, metal material coating process, etc., can solve the problems of reduced overall performance of the coating, uneven powder mixing, poor uniform dispersion effect, etc., to achieve solid Lubrication performance is exhibited, Ag loss is reduced, and uniformity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] A thermal spray composite powder, the thermal spray composite powder comprises the following components by mass percentage:

[0085] NiCrAlY powder 78%

[0086] Cr 2 O 3 Powder 15%

[0087] Ag powder 7%;

[0088] Among them, the average particle size of NiCrAlY powder is 900nm; the Cr 2 O 3 The average particle size of the powder is 60 nm; the average particle size of the Ag powder is 1 μm.

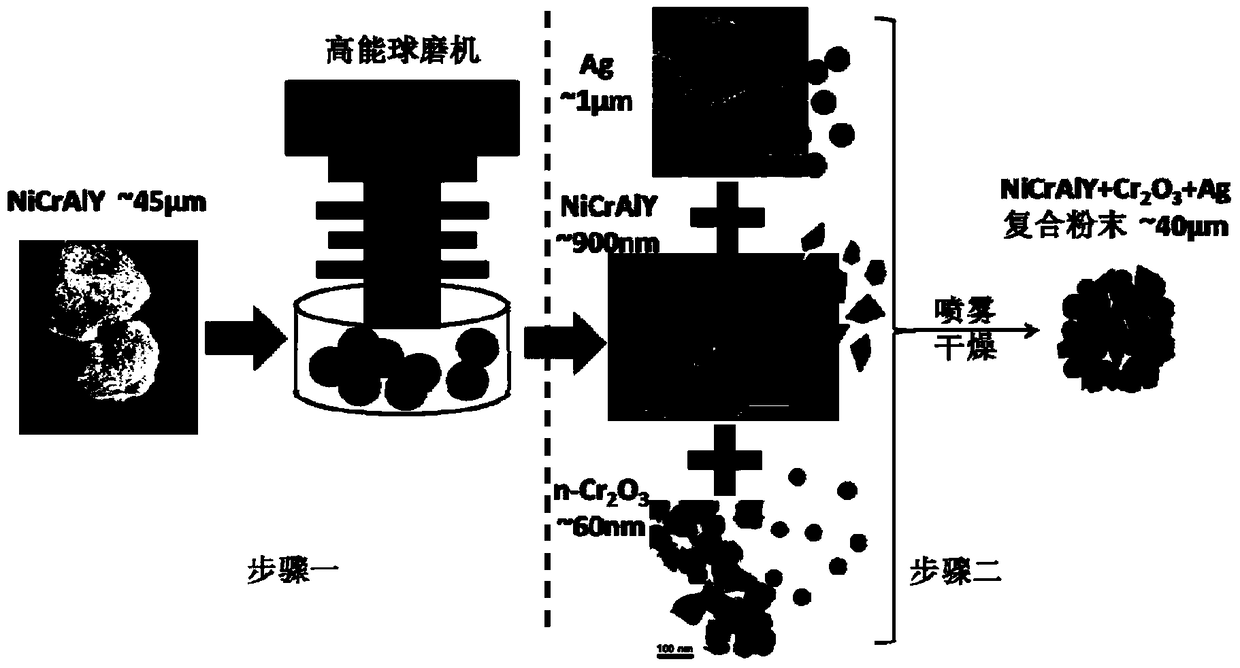

[0089] The preparation method of the thermal spray composite powder is as follows: image 3 As shown, the preparation method comprises the following steps:

[0090] (1) Mix the stainless steel ball, NiCrAlY powder and deionized water in a mass ratio of 25:1:1.5, and put them into the ball mill tank; in the ball mill tank, feed an inert gas with a flow rate and air pressure of 0.2 MPa, and the injection time is 20 minutes; set the rotation speed of the ball mill to 500 rpm, ball mill for 13 hours, add 15 g of tributyl phosphate in the initial stage of ball milling, and add 5...

Embodiment 2

[0109] A thermal spray composite powder, the thermal spray composite powder comprises the following components by mass percentage:

[0110] NiCrAlY powder 74.5%

[0111] Cr 2 O 3 Powder 16.5%

[0112] Ag powder 9%;

[0113] Among them, the average particle size of NiCrAlY powder is 800nm; the Cr 2 O 3 The average particle size of the powder is 100 nm; the average particle size of the Ag powder is 800 nm.

[0114] The preparation method of the thermal spray composite powder is as follows: image 3 As shown, the preparation method comprises the following steps:

[0115] (1) Mix the stainless steel ball, NiCrAlY powder and deionized water in a mass ratio of 22.5:1:1.35, and put them into the ball mill tank; the inert gas with a flow rate and air pressure of 0.2MPa is introduced into the ball mill tank, and the introduction time is 20 minutes; set the rotation speed of the ball mill to 450 rpm, and mill the ball for 14 hours. In the initial stage of ball milling, add tribu...

Embodiment 3

[0119] A thermal spray composite powder, the thermal spray composite powder comprises the following components by mass percentage:

[0120] NiCrAlY powder 81.5%

[0121] Cr 2 O 3 Powder 13.5%

[0122] Ag powder 5%;

[0123] Among them, the average particle size of NiCrAlY powder is 1000nm; the Cr 2 O 3 The average particle size of the powder is 80 nm; the average particle size of the Ag powder is 1200 nm.

[0124] The preparation method of the thermal spray composite powder is as follows: image 3 As shown, the preparation method comprises the following steps:

[0125] (1) Mix stainless steel balls, NiCrAlY powder and deionized water in a mass ratio of 27.5:1:1.65, and put them into a ball mill; the inert gas with a flow rate and air pressure of 0.2 MPa is introduced into the ball mill, and the introduction time is 20 minutes; set the rotation speed of the ball mill to 650 rpm, and mill the ball for 15 hours. In the initial stage of ball milling, add tributyl phosphate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com