Mechanical equipment and method for backfilling slurry in mined-out area

A goaf, mud technology, applied in mining equipment, open-pit mining, filling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

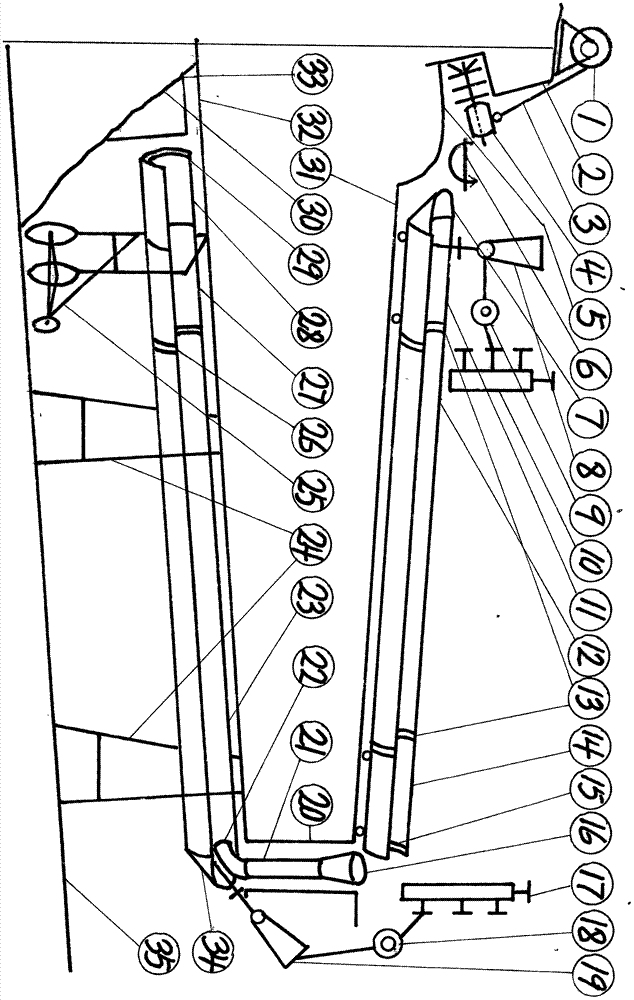

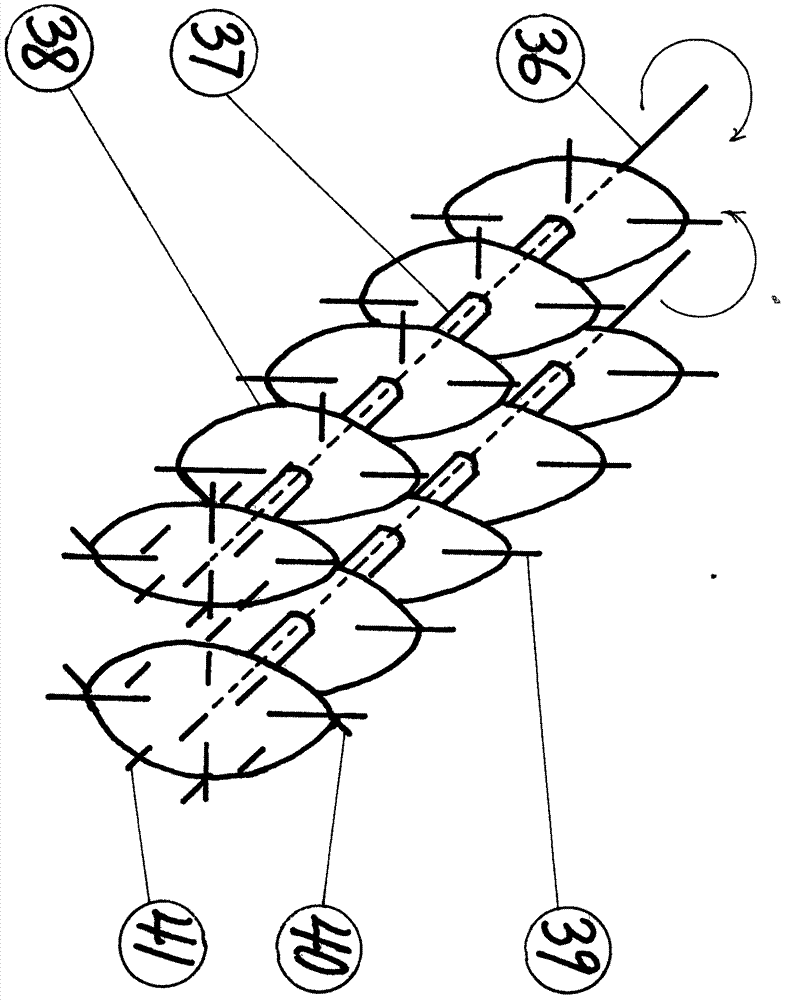

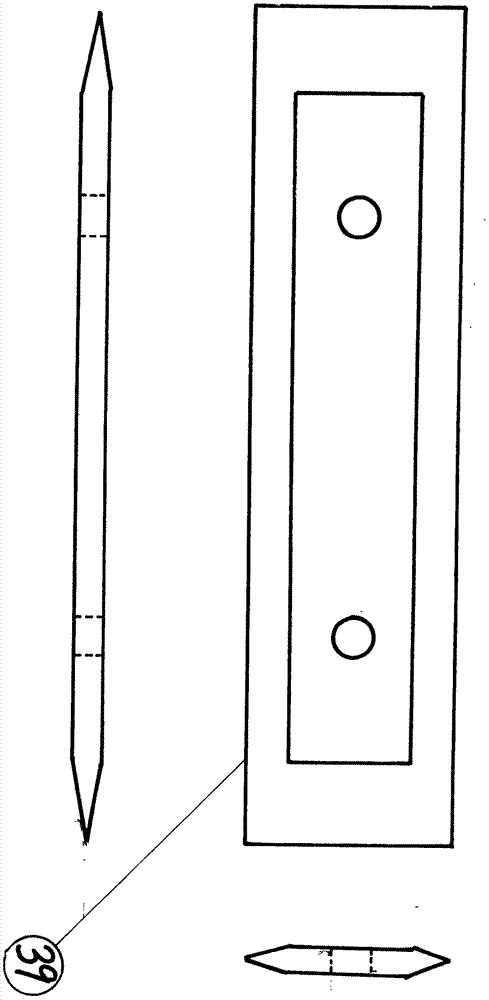

[0044] The present invention will be described in further detail below in combination with 21 drawings and embodiments.

[0045] attached figure 1: Schematic diagram of the mechanical equipment and construction method for mud backfilling in the goaf of the mine. The speed-regulating hoist (1) is placed on the top of the cliff side of the excavation surface (2) of the loess mountain body. The hoisting wire rope (3) is wound on the drum of the speed-regulating hoist (1), and its end is hung with a double-shaft reciprocal (clockwise and counterclockwise) three-way (radial, end-to, oblique) rotation Mowers (4). The two-axis reciprocal (rotating clockwise and counterclockwise) three-way (radial, end-oriented, and oblique) rotary soil cutter (4) is close to the excavation surface (2) of the loess mountain to perform up-and-down reciprocating cutting motion. The loose soil material (5) that has been cut and stripped from the mountain body falls and accumulates on the soil field at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com