U-shaped connecting piece

A horseshoe-shaped connector technology, applied in the field of mechanical parts, can solve the problems of insufficient resistance and impact toughness of connectors, and achieve the effects of fatigue resistance and impact fracture, high tensile strength, high fatigue resistance and impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

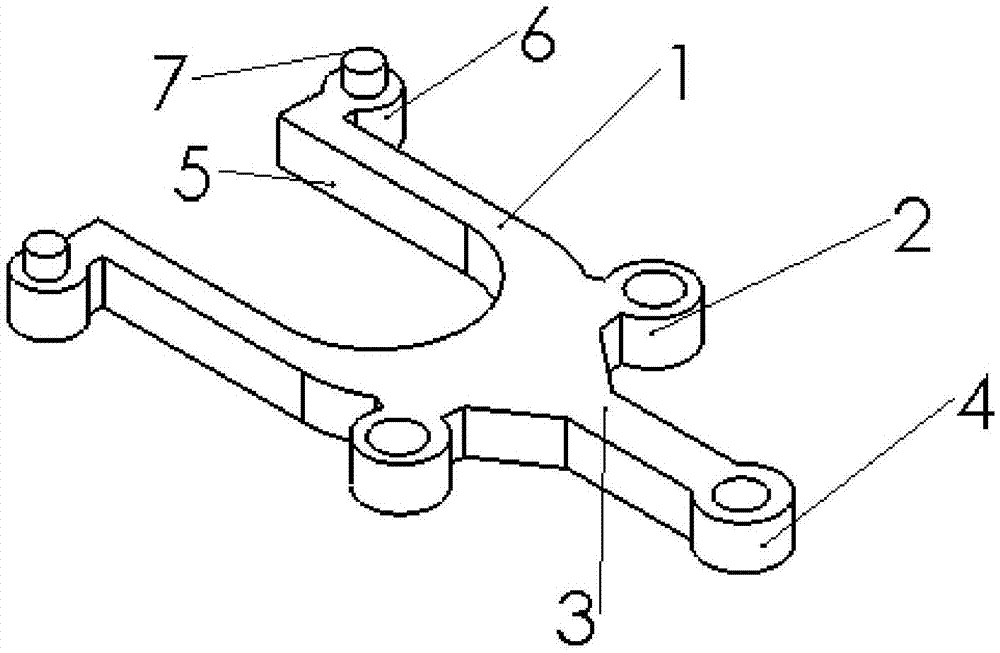

[0018] A horseshoe-shaped connector, comprising a horseshoe-shaped body 1, the two sides of the body 1 are respectively provided with circular first connectors 2, and each first connector 2 is opened with the axis line of the first connector 2. line through hole;

[0019] The head of the body 1 is provided with a main connecting rod 3, on which a circular second connecting head 4 is arranged, and a through hole collinear with its axis line is opened on the second connecting head 4.

[0020] The body 1 is provided with an arc-shaped depression 5 .

[0021] Positioning heads 6 are provided on both sides of the bottom of the body 1 .

[0022] The positioning head 6 is provided with a positioning pin 7 collinear with the axis of the positioning head 6 .

[0023] The upper end surface of the positioning pin 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com