Plastic part quality monitoring method

A technology for quality monitoring and plastic parts, applied in related fields of plastic parts, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

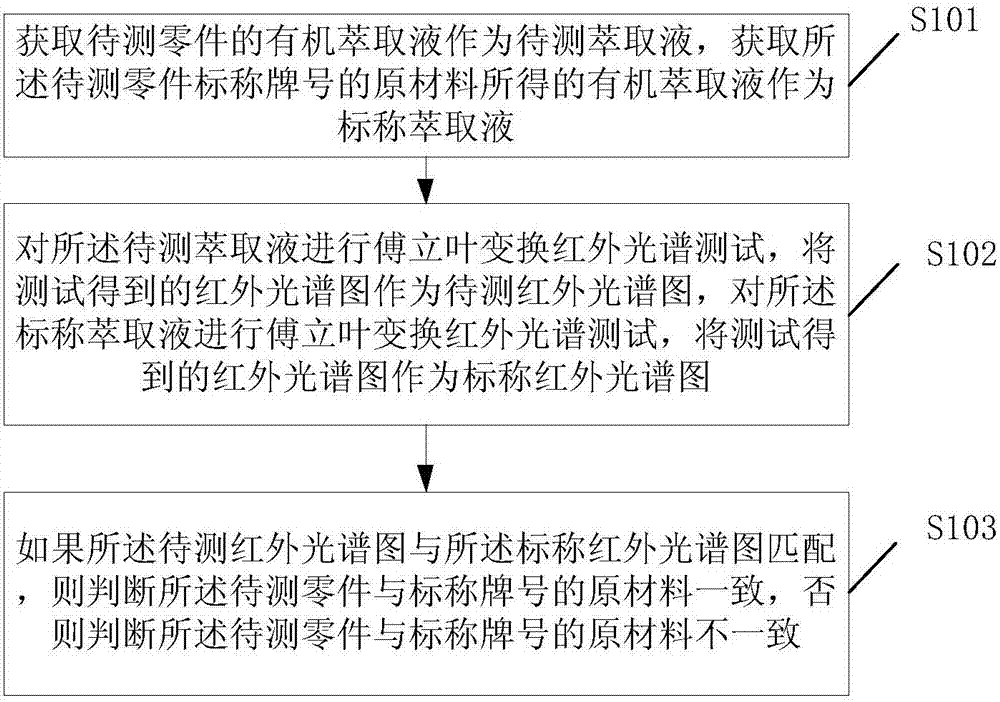

Method used

Image

Examples

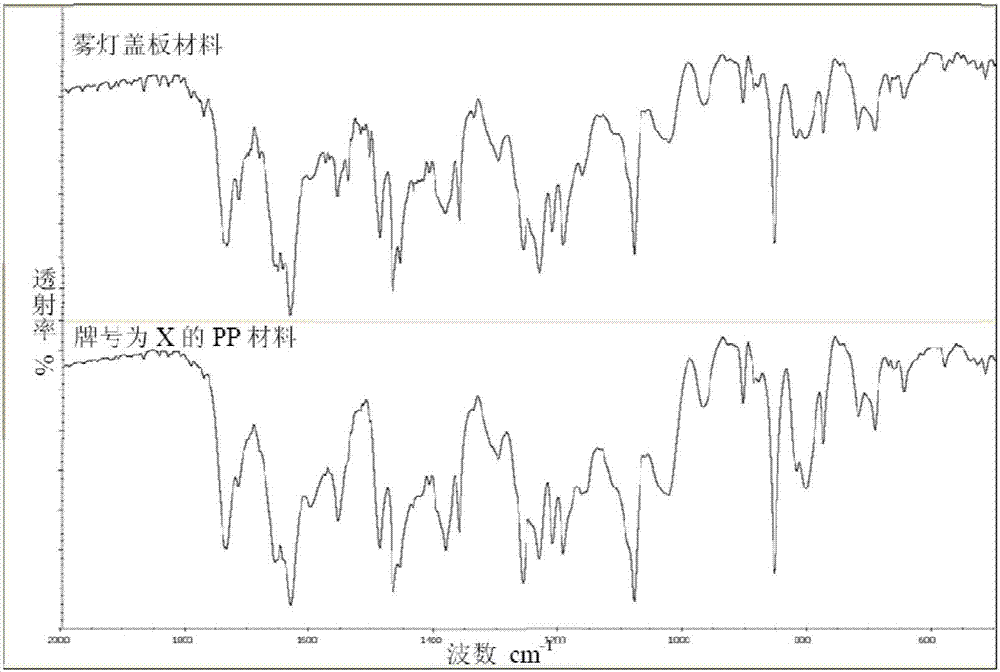

Embodiment 1

[0085] To check whether the grade of the fog lamp cover material (PP) of a certain vehicle model is consistent with the requirements in the drawing: (1) From documents such as the engineering drawings of the fog lamp cover, it is known that the PP material used for this part is Supplier A and the product grade is X's PP raw material. Take 0.5g of the material of this brand, and at the same time use a utility knife to cut 0.5g of the material of the automobile fog lamp cover plate to be tested, chop the two samples into plastic particles less than 0.005g, put them into sample bottles respectively, add methanol / 2.0 mL of the extract with a volume ratio of tetrahydrofuran of 1:1 was left to stand for 96 hours, and then mechanically shaken for 1.5 hours to obtain the extract of the material additive. (2) Pass the obtained two extracts through a 0.45 μm filter head, filter out the small particle impurities in the extract, and then dry them at 80°C for 20 minutes respectively, and ...

Embodiment 2

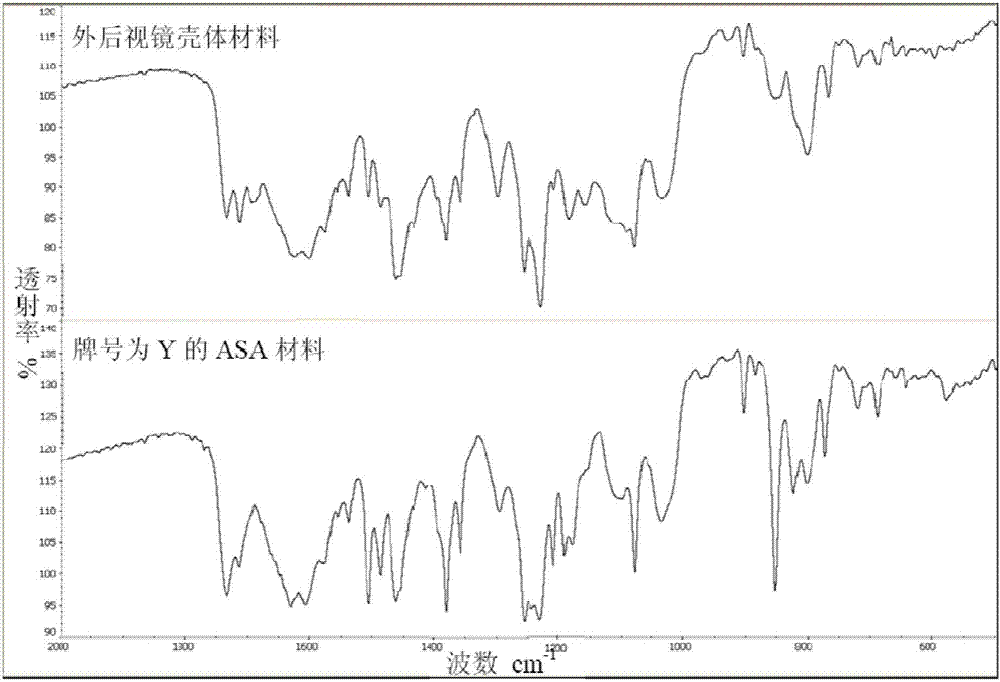

[0086] Best Embodiment 2: The steps of the quality monitoring method for plastic parts are as follows.

[0087] To check whether the grade of the material (ASA) of the exterior rearview mirror housing of a certain vehicle model is consistent with the requirements in the drawings: (1) According to documents such as the engineering drawings of the exterior rearview mirror, the ASA material used for this part is a product of supplier B ASA material whose brand is Y. Take 1.0g of the material of this grade, and at the same time use a utility knife to cut 1.0g of the material of the car exterior rearview mirror housing parts to be tested, chop the two samples into plastic particles less than 0.005g, put them into sample bottles, add 10mL of tetrahydrofuran was used as a solvent, and stood for 20 minutes to dissolve the materials and additives in the materials in the dissolving agent to form a polymer solution; then add 10mL of methanol as a precipitating agent to precipitate the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com