Pig culturing equipment capable of automatically controlling quantified feeding

A pig and equipment technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of slow speed, time-consuming and laborious, troublesome manual feeding, automatic adjustment control, etc., to reduce labor force, simple structure, and reduce feed waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

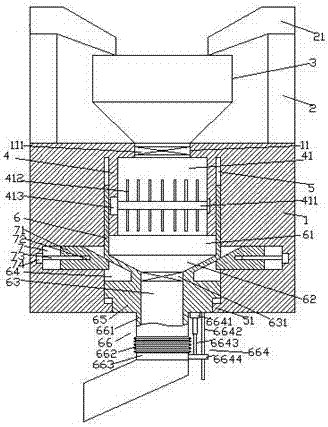

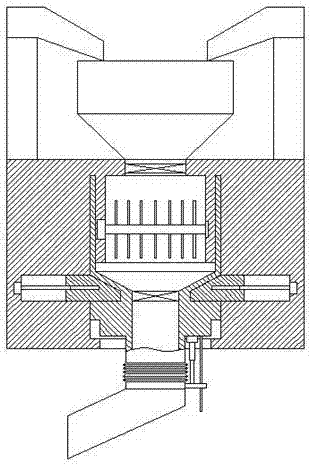

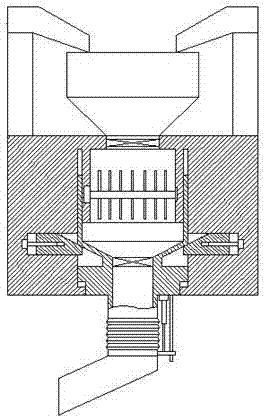

[0021] Such as Figure 1-Figure 5 As shown, a pig breeding equipment that can automatically control quantitative feeding of the present invention includes a body 1 and a feed hopper 3 fixedly arranged on the top of the body 1, and the body 1 on the left and right sides of the feed hopper 3 The top is fixed with a support rod 2, the top of the support rod 2 is provided with a feed hopper 21, and the inside of the feed hopper 21 is extended to the top of the feed hopper 3, and the body 1 is provided with a first cavity 5. A protruding limit ring 51 is provided at the bottom edge of the first cavity 5, and slide grooves 7 are symmetrically arranged on the inner walls of the left and right sides of the first cavity 5 near the bottom, and the first cavity 5 There is a movable part 6 that is connected by a sliding fit, and the top of the movable part 6 is provided with a second cavity 61, and the top of the second cavity 61 is slidably connected to the joint sleeve 4, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com