Workpiece grinding component capable of collecting fragments

A workpiece and grinding technology, which is applied in the field of mechanical processing devices, can solve problems such as precision or service life, and achieve the effect of stable structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

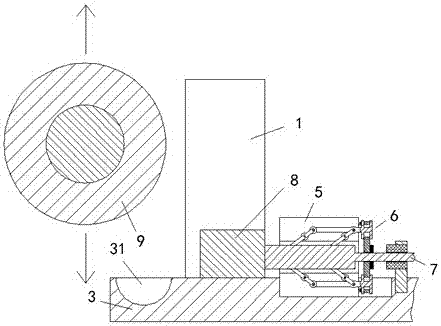

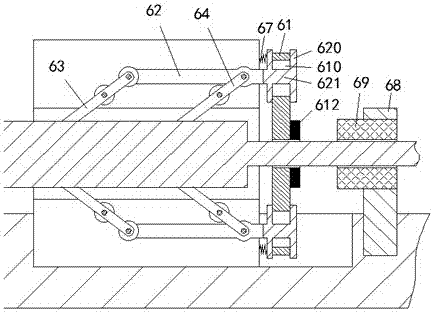

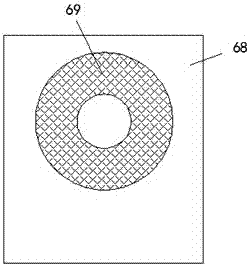

[0009] Combine below Figure 1-3 The present invention will be described in detail.

[0010] combine Figure 1-3 , according to an embodiment of the present invention, the chip-collecting workpiece grinding assembly is used for grinding a workpiece 1, including a grinding wheel 9 and a base 3 for supporting and feeding the workpiece 1, so A workpiece holder 8 for clamping the workpiece 1 is slidably supported on the base 3, and the workpiece holder 8 can be pushed to the left by the feed drive rod 7 to make the workpiece 1 against the grinding wheel 9. A collecting groove 31 is arranged on the left side of the workpiece holder 8 on the base 3, and the collecting groove 31 is hemispherical for use when the grinding wheel 9 grinds the workpiece 1 The debris produced by grinding is collected and processed. The collection groove 31 is hemispherical so as to facilitate the removal of the collected debris. The block 5 and the feed abutment assembly 6 installed on the fixed block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com