Air blow-melting continuous ice breaking mechanism

An air and icebreaker technology, applied in icebreakers, motor vehicles, water conservancy projects, etc., can solve problems such as slow ice breaking speed, and achieve the effect of improving ice breaking efficiency and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

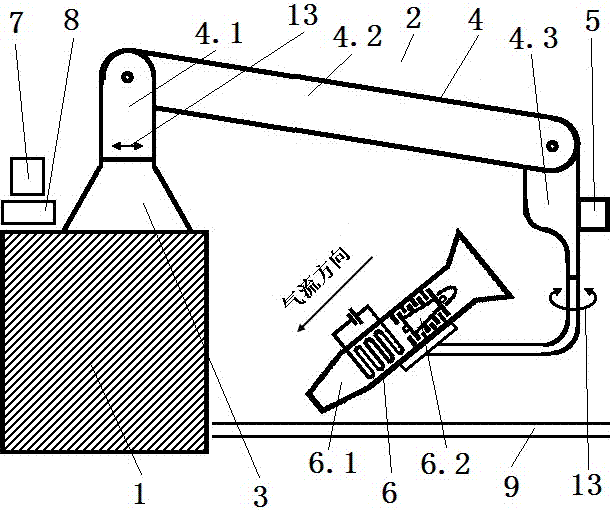

[0029] The following is attached with the manual figure 1 , 2 The present invention is further described.

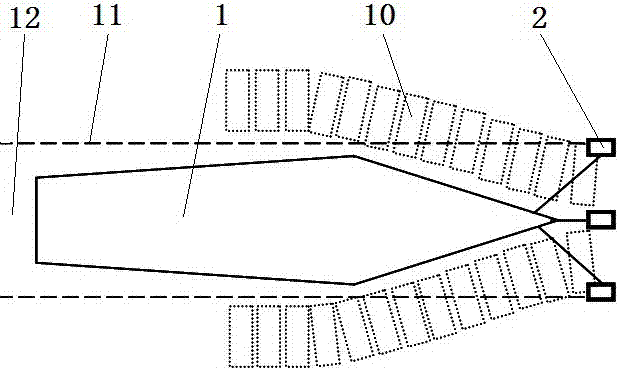

[0030] An icebreaker (1) using the structure of the present invention operates in the ice area, and its continuous icebreaking mechanism is as follows: figure 1 , the air blowing and melting continuous ice breaking mechanism (2) includes a bracket (3), a mechanical arm (4), a distance measuring sensor (5), a high temperature and high pressure air injector (6), and a control center (7).

[0031] The bracket (3) is fixed on the hull of the icebreaker (1) to connect and support the mechanical arm (4).

[0032] The mechanical arm (4) is connected to and supports the high-temperature and high-pressure jet (6), and is used to adjust the position and height of the high-temperature and high-pressure jet (6), so that the high-temperature and high-pressure jet (6) is relatively close to but not in contact with the ice layer (9 ) surface; also used to connect and fix the rangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com