A method for preparing a steel column foot anchor bolt in place structure

An anchor bolt and steel column technology is applied in the field of steel structure building construction, which can solve the problems of slow speed and low efficiency, and achieve the effects of reducing engineering costs, simplifying construction procedures and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

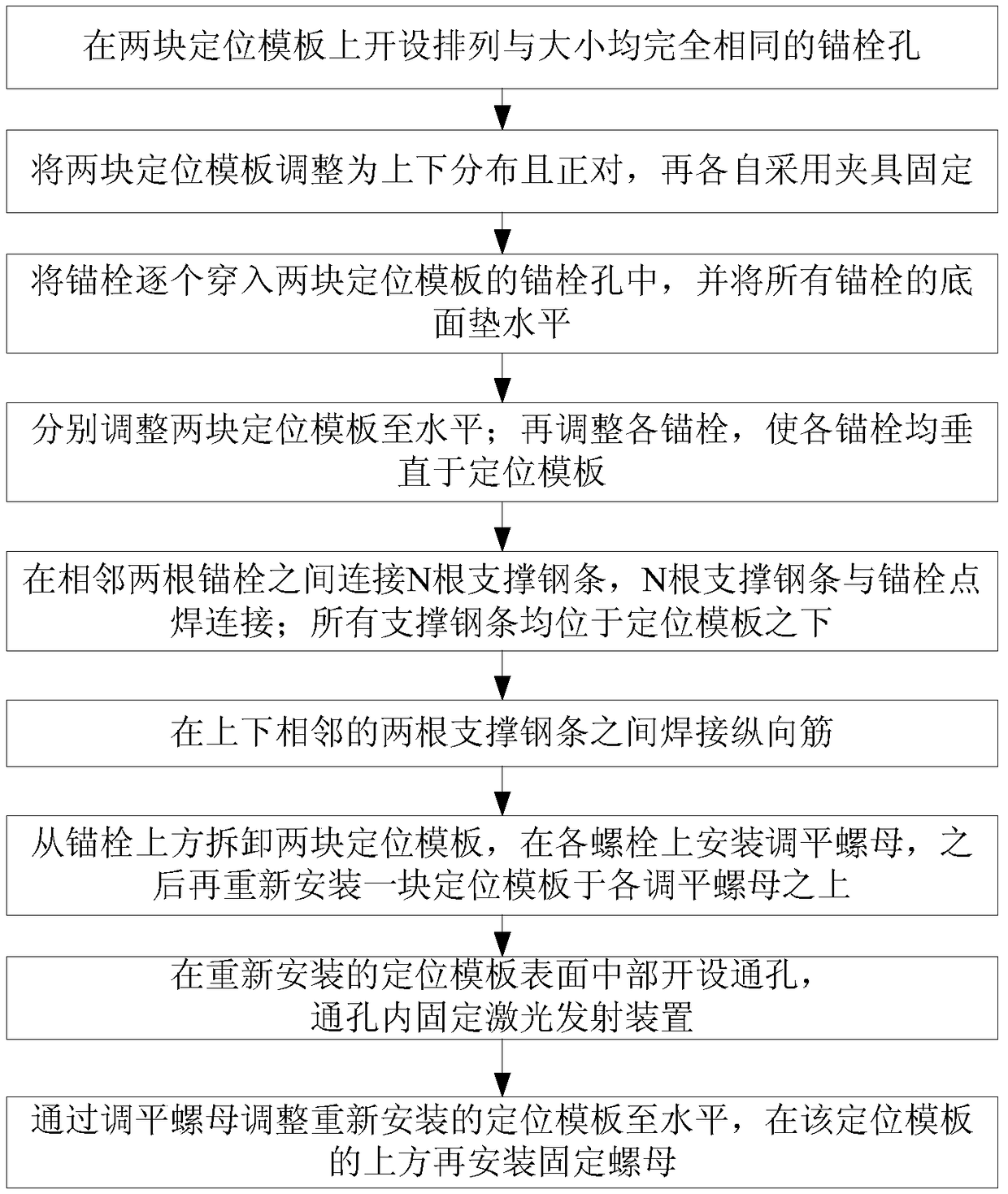

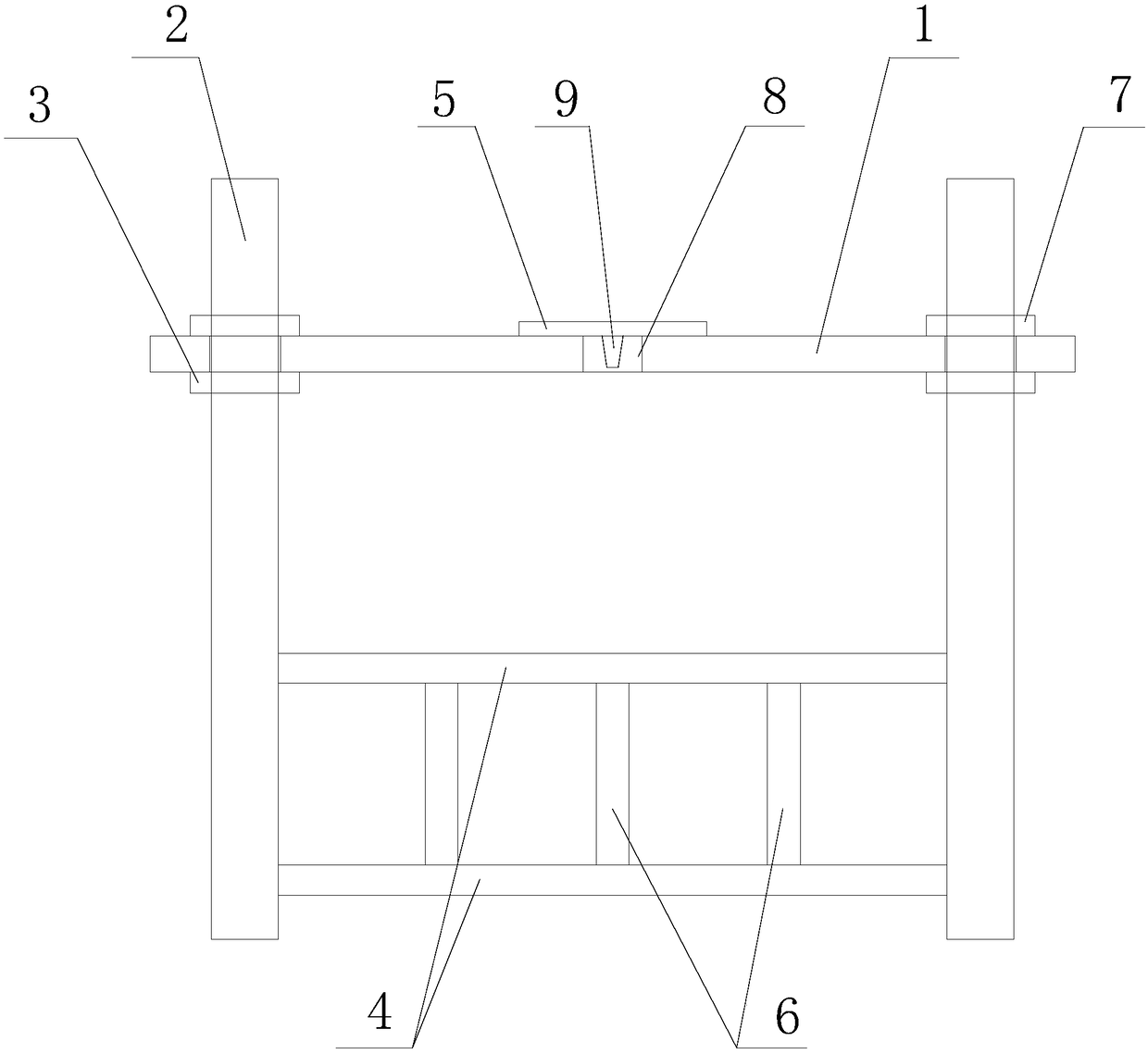

[0030] Such as figure 1 and figure 2 The preparation method of a steel column base anchor bolt in place structure shown includes the following steps: (a) opening anchor bolt holes with the same arrangement and size on the two positioning templates, and adjusting the two positioning templates to be up and down (b) Insert the anchor bolts into the anchor bolt holes of the two positioning templates one by one, and pad the bottom surfaces of all the anchor bolts horizontally; (c) Adjust the two positioning templates to the level respectively; Then adjust the anchor bolts so that each anchor bolt is perpendicular to the positioning template; (d) connect the supporting steel bars between two adjacent anchor bolts, and the supporting steel bars are spot-welded with the anchor bolts; (e) Remove two positioning templates from above the anchor bolts, install leveling nuts on each bolt, and then reinstall a positioning template on each leveling nut; install and fix the positioning temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com