Open section tunnel structure with cast-in-place and prefabricating assembling combined

A prefabricated assembly and tunnel structure technology, which is applied to underwater structures, infrastructure engineering, protection devices, etc., can solve the problems of large investment in pumping concrete vehicles, many risk sources of construction safety, and large temporary construction area , to achieve the effect of reducing the impact of surrounding traffic and residents' life, reducing the amount of cast-in-place operations, and reducing the amount of steel binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

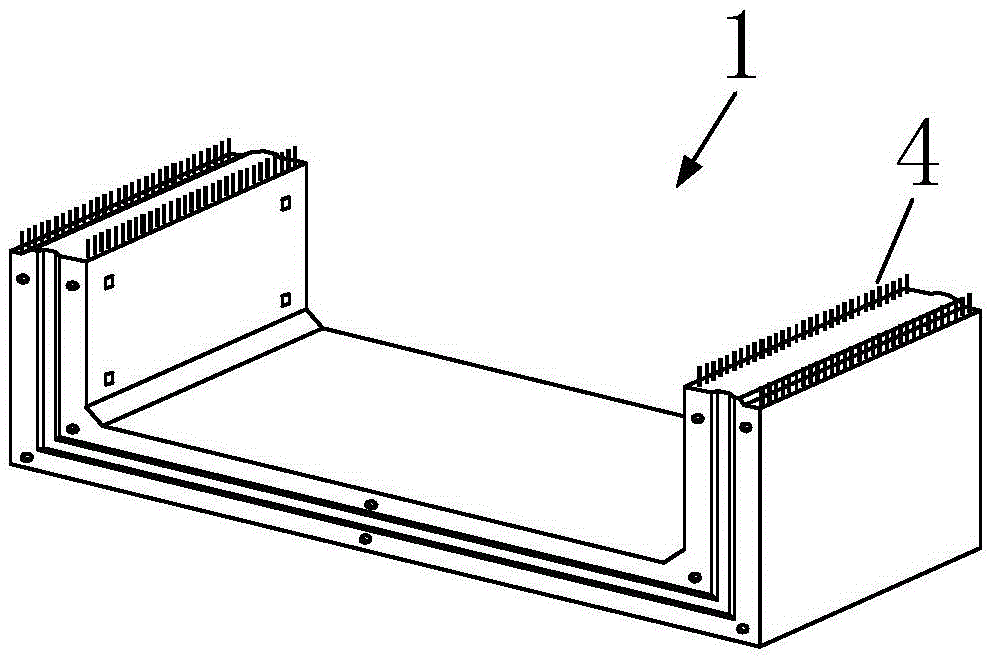

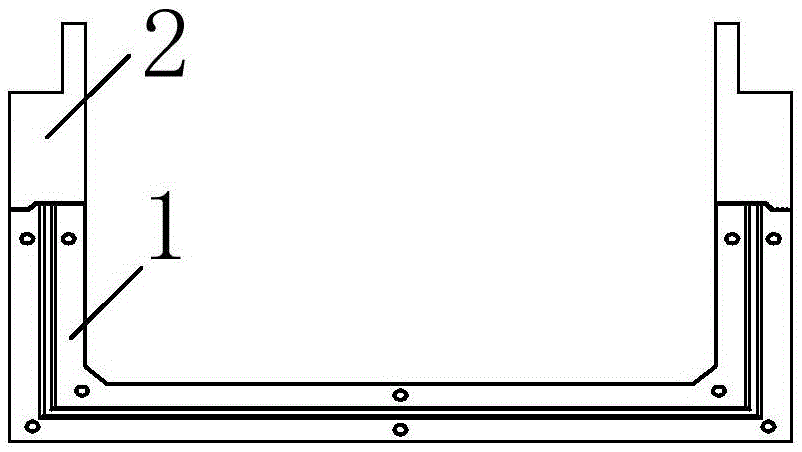

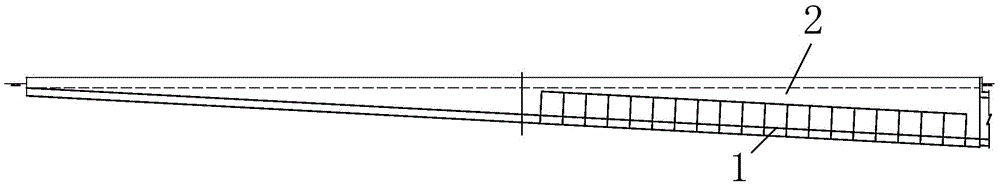

[0033] The purpose of the present invention is achieved through the following technical solutions: as Figure 1 ~ Figure 4 As shown, the open section tunnel structure of the combination of cast-in-place and prefabricated assembly provided by this embodiment includes: a prefabricated assembled component (such as figure 1 As shown), the section is U-shaped, so it can be called: prefabricated U-shaped assembled component 1; the part above the prefabricated U-shaped assembled component (including the ear wall) is cast-in-place component 2; 1 The tunnel structure that together constitutes the open section (such as figure 1 shown).

[0034] In addition, a tongue and groove is provided on the upper side of the side wall of the prefabricated U-shaped assembled component 1 to increase the seepage path.

[0035] When the cast-in-place component 2 of the upper part is cast in-situ, a water-stop rubber strip is buried in the upper part of the tongue and groove, which is used to block th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com