Stope filling body slope reinforcing method

A technology of backfill and side help, which is applied in the fields of backfill, ground mining, mining equipment, etc., to reduce safety risks, improve tensile strength, and improve safety environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

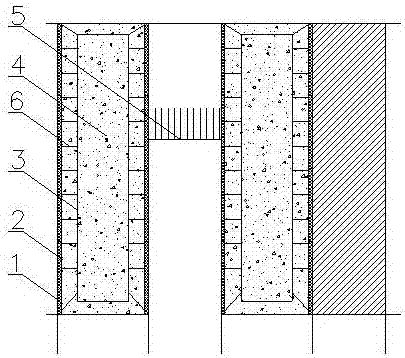

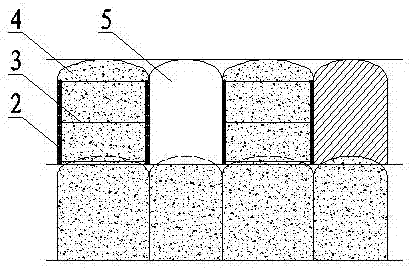

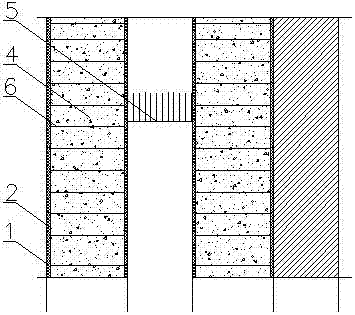

[0014] The construction scheme of a side reinforcement method of a stope filling body proposed by the present invention is as follows:

[0015] (1) After the mining of the underground stope is completed and the ore is cleared, install lighting equipment, clean the stope roof and side pumice, and carry out timely support operations for unstable areas to prevent roof caving in subsequent operations.

[0016] (2) After the support work is completed, the steel mesh or bamboo mesh is vertically hung along the side of the stope to make it close to the rock side, and the steel mesh or bamboo mesh is tied with lead wire, and then the Each piece of steel mesh or bamboo mesh is tied to the iron wire surrounding the stope (see figure 1 , 2 ), when the transverse span of the stope is small, the left and right steel mesh pieces or bamboo mesh pieces can be directly connected with iron wires (see image 3 ,refer to figure 2 ), when the stope filling height exceeds 2 meters, it can be er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com