Test method for transport law of hydrate layer output fine sand in gravel layer and test device thereof

A test method and gravel layer technology, which is applied in the field of marine natural gas hydrate resource development engineering, can solve the problems of not considering the migration law of fine sand in the formation of sand control medium at the bottom of the well, and the inability to analyze the law of sand production at the bottom of the well, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

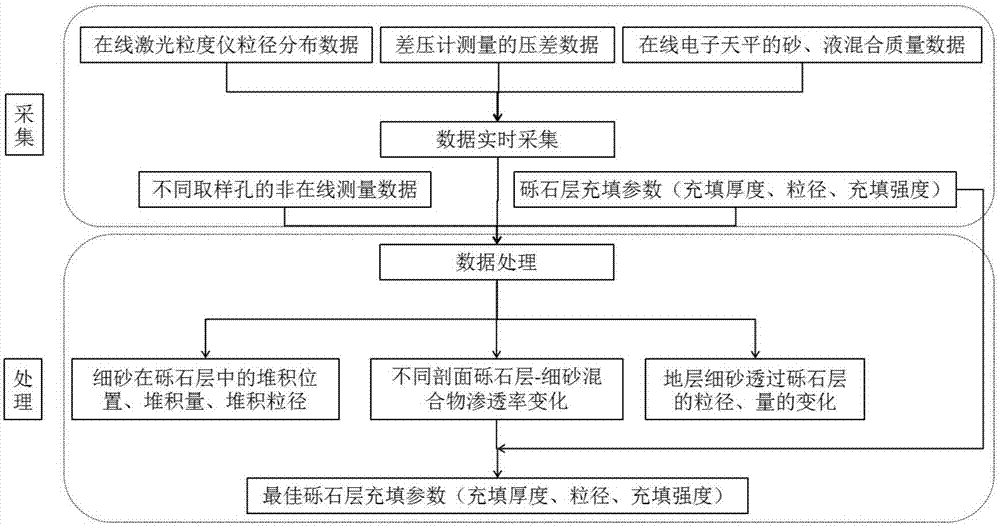

[0069] Specifically, in the present invention, the test method for the migration law of the fine sand produced in the hydrate layer in the gravel layer includes the following steps:

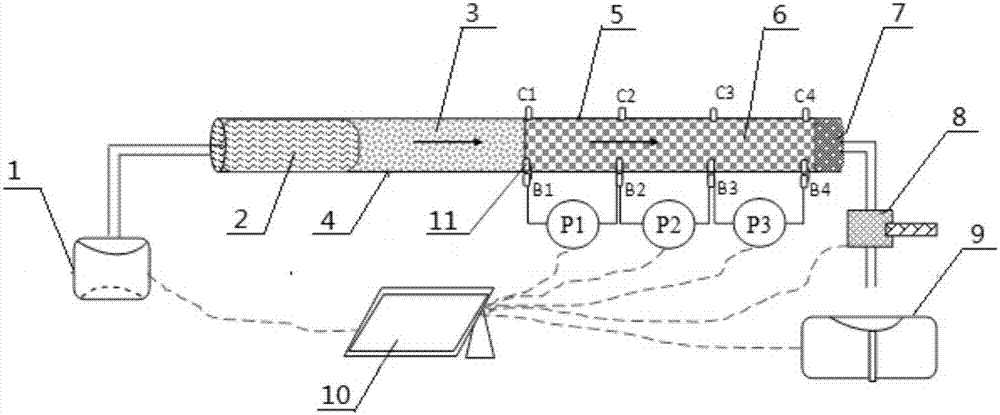

[0070] (1) Take a one-dimensional non-perforated sand-filling model sub-pipe and a simulated gravel layer sand-filling sub-pipe with openings of the same inner and outer diameters, and put a certain degree of compaction, a certain thickness, and a certain amount of gravel into the gravel filling sub-pipe according to actual needs. The simulated gravel layer is filled with the simulated size, the sub-pipe sampling hole is blocked with a plug, and the pressure measurement hole is installed with a pressure pipe and connected with a high-precision differential pressure sensor. The main function of the pressure induction pipe is to ensure that the differential pressure value measured by the differential pressure gauge is the flow pressure difference inside the filling layer, so as to further avoid the ...

Embodiment 2

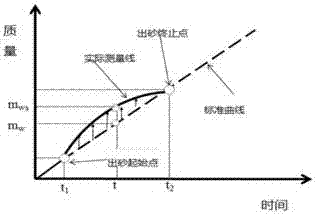

[0082] Such as figure 1 and figure 2 As shown, the test method for the migration law of fine sand produced in the hydrate layer in the gravel layer includes the following steps:

[0083] (1) Take the sand filling model to simulate the gravel layer sub-pipe 5, the sub-pipe has a total length of 20cm, fill it with 40-60 mesh filling gravel 6, the thickness of the filling layer is 15cm, compact it with a hydraulic compaction device, and the filling strength is 1.5kg / m ;

[0084] (2) The sand filling model is used to simulate filling formation sand tube pressure measuring holes B1, B2, B3, B4, insert pressure induction pipe 11, and install high-precision differential pressure gauges P1, P2, P3, and plug sampling holes C1~C4 with plugs die;

[0085] (3) Take the sand filling model to simulate the filling formation sand pipe 4, connect it with the sand filling model to simulate the filling formation sand pipe 4 through a quick joint, and use the sand filling model to simulate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com