Ultrasonic flaw detection method of heavy-thickness austenitic stainless steel welded splices

A technology of austenitic stainless steel and welded joints, applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, and analysis materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solutions of the present invention will be further described in detail below through specific examples.

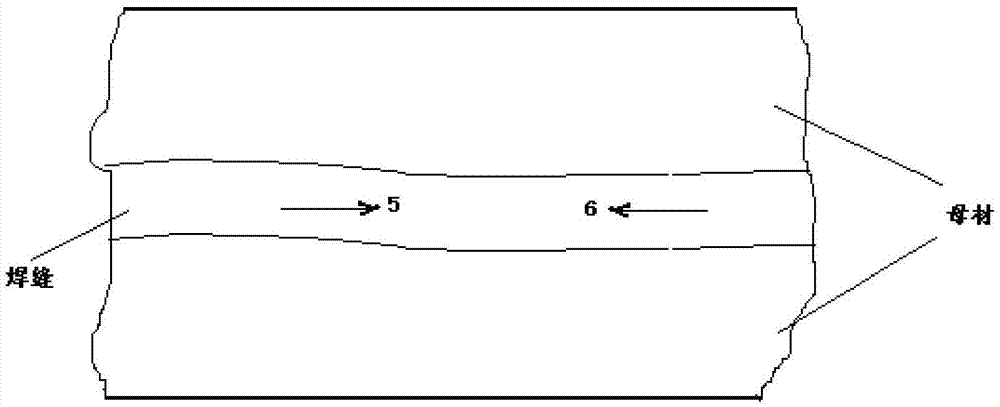

[0075] In this embodiment, an ultrasonic flaw detection method for large-thickness austenitic stainless steel welded joints uses a longitudinal wave double-crystal angle probe to perform oblique-wave direct-wave method on single-sided welds of austenitic stainless steel with a thickness of ≤163 mm from one side and both sides carry out a scan test;

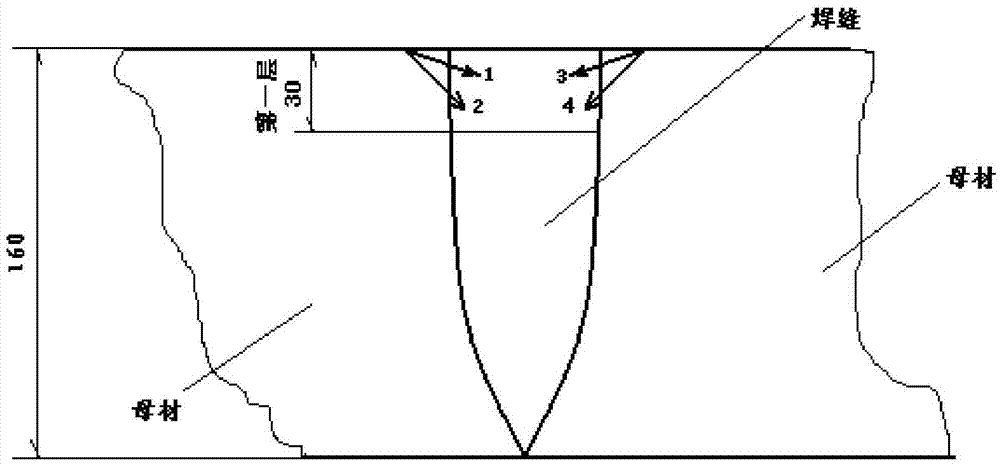

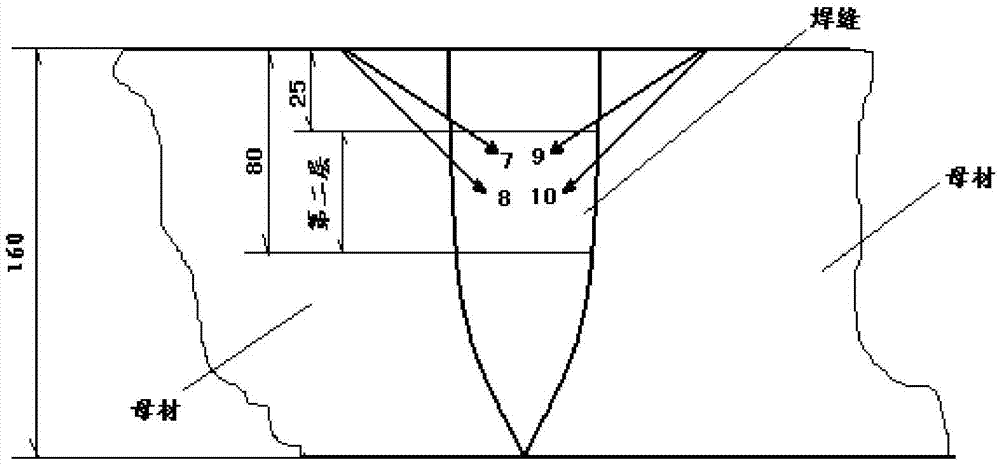

[0076] During scanning, the weld seam is layered in the thickness direction, each layer is combined with probes with different focal lengths and angles for detection, and an area covered by each other is set between adjacent two layers of probes; the specific steps are as follows:

[0077] (1) Delamination in the thickness direction

[0078] The welds with a thickness of ≤163mm are divided into three layers in the thickness direction for inspection. The detection range of each layer is: the first layer de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com