Virtual assembly system based on marine diesel engine

A technology of marine diesel engine and virtual assembly, which is applied to the simulation device, simulator, transportation and packaging of space navigation conditions, can solve the problems of low safety, limited teaching by teachers, uneven teaching quality inspection, etc., to improve hands-on ability, and the effect of improving teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The patent of the present invention will be further explained below in conjunction with the drawings. Take the fuel system as an example.

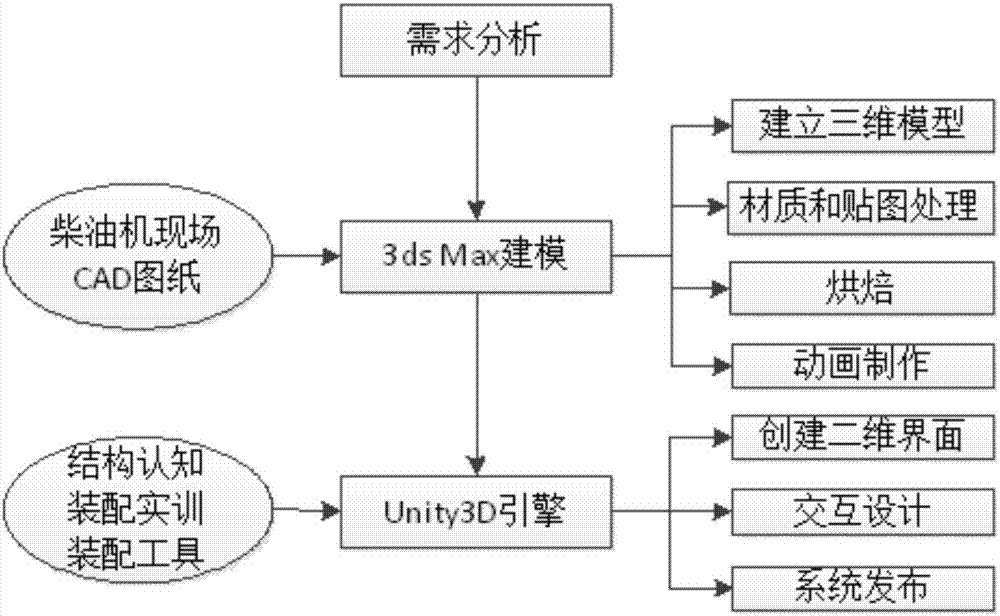

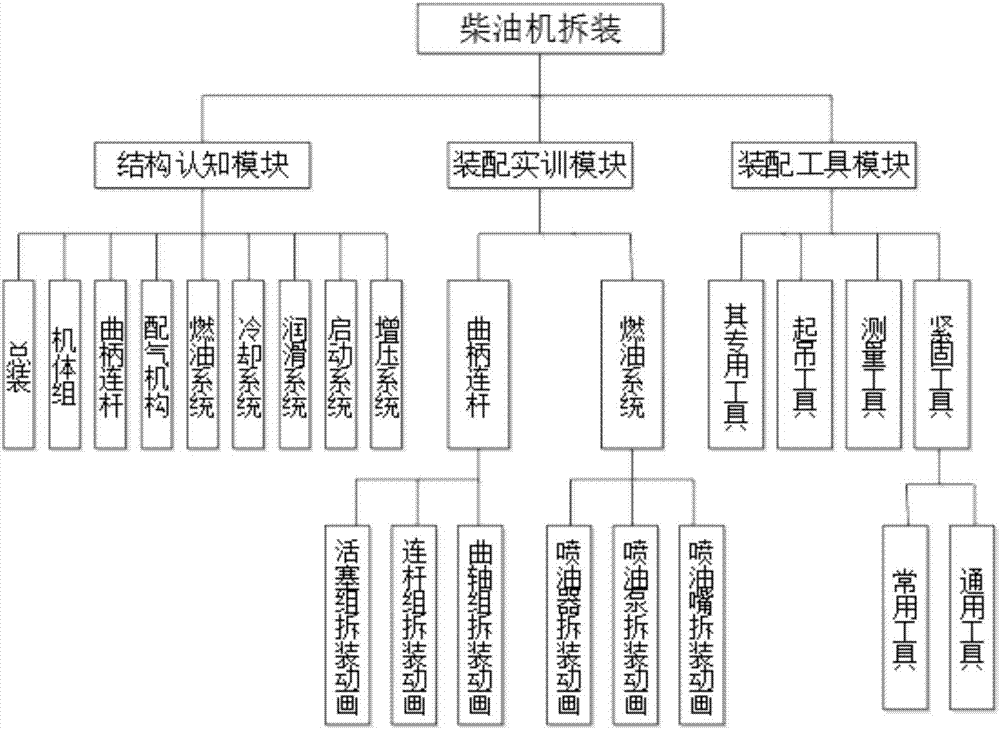

[0027] A virtual assembly system based on marine diesel engine, used to disassemble and assemble the three-dimensional diesel engine model modeled and rendered by 3dsMax. The virtual assembly system mainly builds diesel engine model by 3dsMax. The diesel engine model includes the final assembly, body group, crank connecting rod, Valve train, fuel system, cooling system, lubrication system, starting system and booster system. The 3D diesel engine model is converted into FBX format and imported into Unity3D to create a virtual assembly system for marine diesel engine. In Unity3D, the disassembly and assembly functions of each part of the diesel engine model are set. The diesel engine model includes the general assembly and multiple sub-assemblies. The virtual assembly system mainly includes a structure recognition module, an assembly tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com