Washing machine motor control method

A technology for motor control and washing machine, applied in the direction of AC motor control, general control strategy, control system, etc., can solve the problems of low efficiency, large volume, low dehydration speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the drawings and specific embodiments.

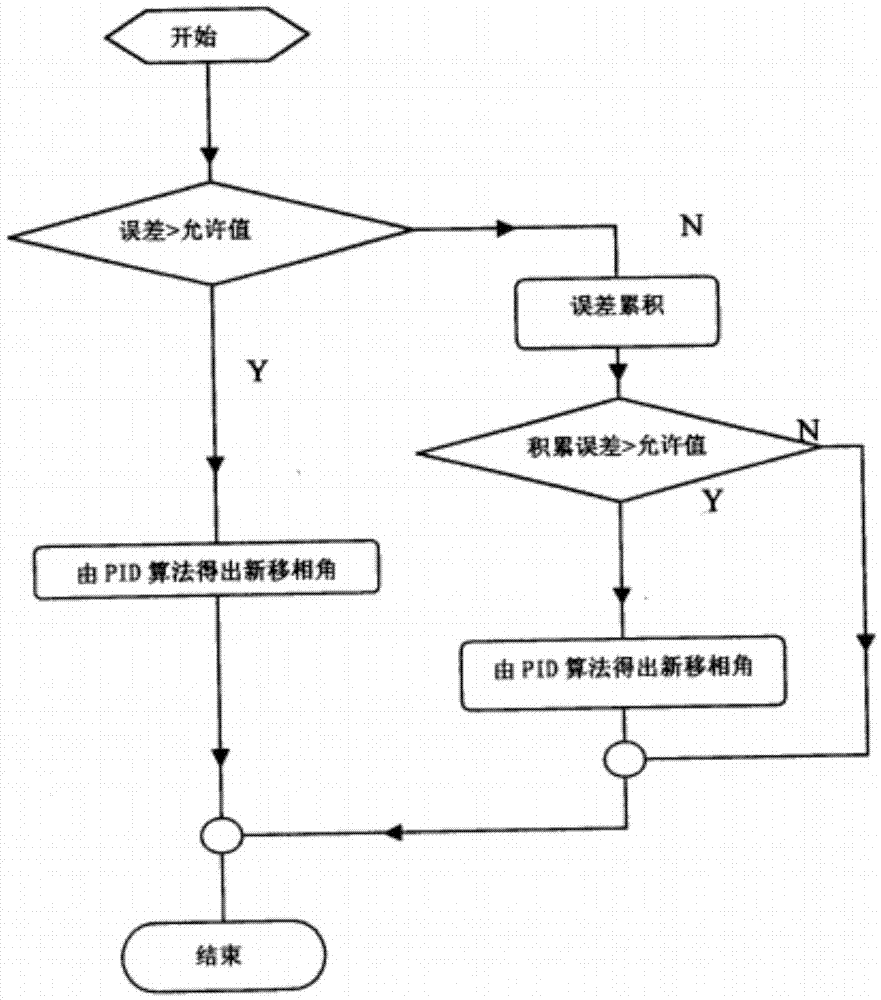

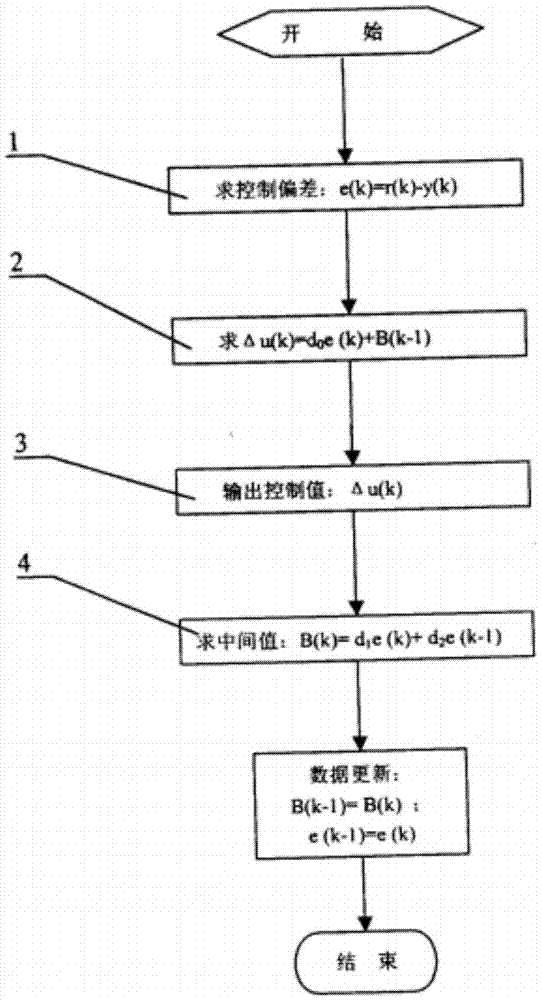

[0009] Such as figure 1 , 2 As shown, the present invention uses a two-speed motor with a tachometer motor and a washing machine computer program controller. The output waveform of the tachometer motor is shaped into a pulse signal, which triggers the single-chip microcomputer and generates an interrupt. The interrupt service program obtains the motor speed parameter y(k) , Find the control deviation e(k)1 according to the set values r(k) and y(k), and find the output control value Δu(k)2 according to the deviation; to meet the real-time control value, first output the control value Δu( k)3, and then calculate the intermediate value B(k)4, and finally update the last data with this data. R(k) is the set value, y(k) is the feedback value, d0, d1, and d2 are the PID parameters. According to the calculated control deviation, the phase shift angle is changed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com