Firing Technology of Large Nixing Pottery Vessels

A technology of Nixing pottery and Nixing pottery clay, which is applied in the field of firing technology of Nixing pottery, can solve the problem of uneven hardness, achieve the effects of consistent hardness, synchronous dehydration, and avoid cracking defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

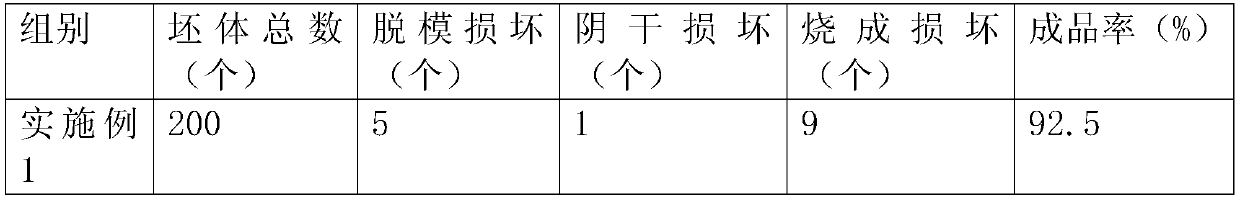

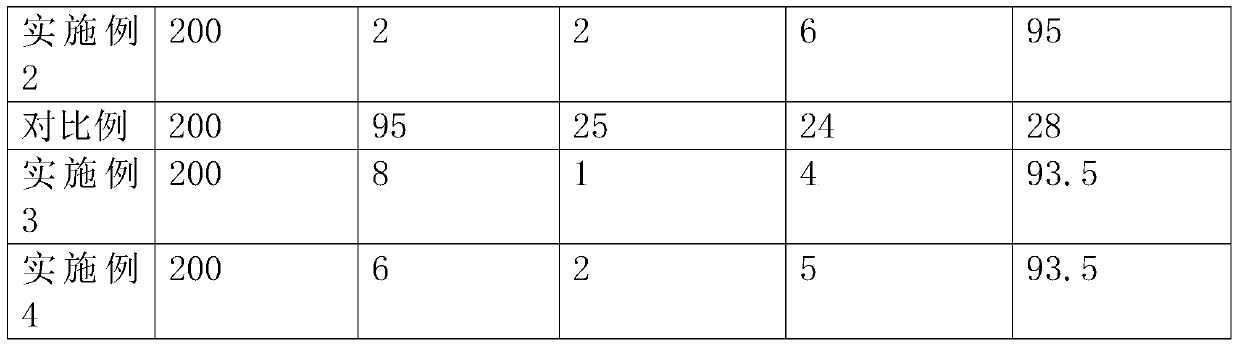

Embodiment 1

[0019] 1) Mix Dongni and Xini at a weight ratio of 4:6 to obtain Nixing pottery clay, and add 0.1% of its weight of EuCl to Nixing pottery clay 2 , through a series of processes such as grinding, pressure filtration, vacuum mud refining, and aging to make mud with a moisture content of 25%;

[0020] 2) Inject the mud into the gypsum mold, and the mold absorbs the moisture in the mud. When the thickness of the green body reaches 10cm, discharge the excess mud. When the water content of the green body drops to 18%, take it out from the mold to obtain Nixing Tao Da 200 vase blanks (maximum diameter 60cm, height 1m). Among them, there were 195 intact blanks, and 5 were slightly deformed;

[0021] 3) Dry 195 intact green bodies in the shade and send them into the kiln for firing. First, raise the temperature inside the kiln to 450°C at a rate of 80°C per hour, and then increase the temperature at a rate of 140°C per hour. Raise the temperature to 1100°C, keep it warm for 1 hour, ...

Embodiment 2

[0023] 1) Mix Dongni and Xini at a weight ratio of 6:4 to obtain Nixing pottery clay, and add 1% of its weight of EuCl to Nixing pottery clay 2 , through a series of processes of grinding, pressing, vacuum mud refining, and aging to make mud with a moisture content of 28%;

[0024] 2) Inject the mud into the gypsum mold, and the mold absorbs the moisture in the mud. When the thickness of the green body reaches 10cm, discharge the excess mud. When the water content of the green body drops to 20%, take it out from the mold to obtain Nixing Tao Da 200 vase blanks (maximum diameter 60cm, height 1m). Among them, 198 were intact green bodies, and 2 were slightly deformed;

[0025] 3) Dry 198 intact green bodies in the shade and send them into the kiln for firing. First, raise the temperature inside the kiln to 550°C at a rate of 130°C per hour, and then increase the temperature at a rate of 180°C per hour. Raise the temperature to 1200°C, keep it warm for 2 hours, stop heating, an...

Embodiment 3

[0031]1) Mix Dongni and Xini at a weight ratio of 5:5 to obtain Nixing pottery clay, and add 0.5% of its weight of EuCl to Nixing pottery clay 2 , through a series of processes of grinding, pressing, vacuum mud refining, and aging to make mud with a moisture content of 26%;

[0032] 2) Inject the mud into the plaster mold, and the mould absorbs the moisture in the mud. When the thickness of the green body reaches 10cm, discharge the excess mud. When the water content of the green body drops to 19%, take it out from the mold to obtain Nixing Tao Da 200 vase blanks (maximum diameter 60cm, height 1m). Among them, 192 were intact green bodies, and 8 were slightly deformed;

[0033] 3) Dry 195 intact green bodies in the shade and send them into the kiln for firing. First, raise the temperature in the kiln to 500°C at a rate of 110°C per hour, and then increase the temperature at a rate of 160°C per hour. Raise the temperature to 1150°C, keep it warm for 1.5 hours, stop heating, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com