Apparatus for testing bending strain critical performance of superconducting strand

A technology of bending strain and critical performance, which is applied in the direction of testing the strength of materials by applying a stable bending force, can solve problems such as unsatisfactory requirements, and achieve the effects of shortening the time for changing samples, reliable connection and contact, and reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

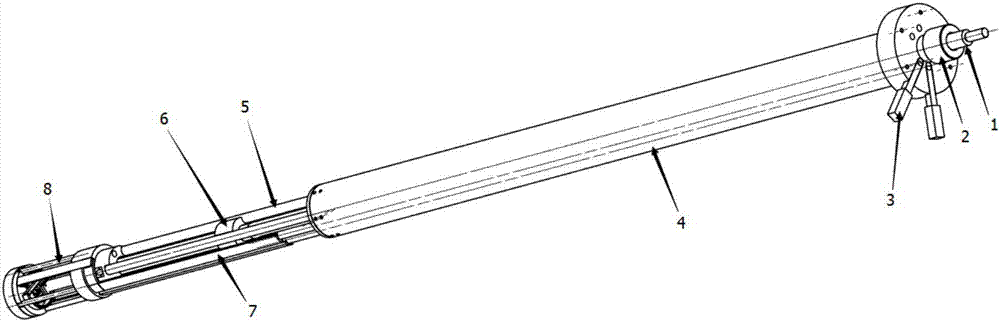

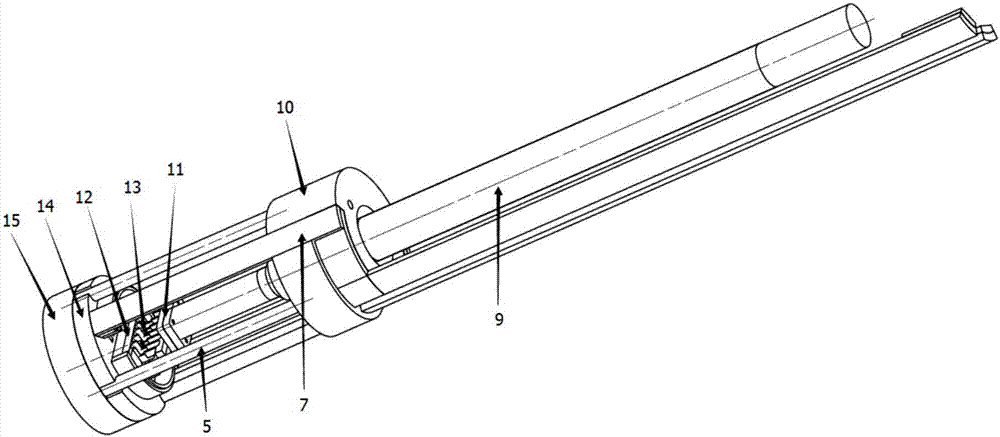

[0026] like figure 1 , 2 As shown, a superconducting strand bending strain critical performance testing device includes a sample rod 4, an upper stress loading rod 1, a lower stress loading rod 9, a support rod 5, an upper current lead 3, a lower current lead 7 and a bending test Module 8, the sample rod 4 is a sleeve structure, the upper stress loading rod 1 and the lower stress loading rod 9 are connected by the loading rod guide connecting block 6, and the upper stress loading rod 1 and the lower stress loading rod 9 are located in the sample rod 5. Internally, the upper end of the upper stress loading rod 1 protrudes from the upper end of the sample rod 4, and a dynamic sealing device 2 is provided on the upper end of the sample rod 4. The lower end of the lower stress loading rod 9 protrudes from the lower end of the sample rod 4, and the lower The lower end of the stress loading rod 9 is connected to the bending test module 8, the bending test module 8 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com