Negative pressure sealing structure and negative pressure sealing method and applications

A technology of sealing structure and sealing pressure, which is applied in applications, home appliances, kitchen appliances, etc., can solve the problem of laborious insertion/removal of sealing pistons, and achieve the effects of improving user experience, increasing convenience of use, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

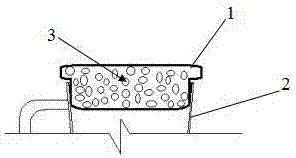

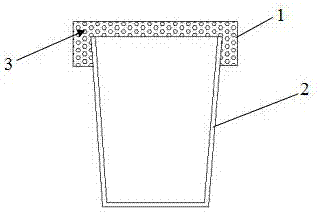

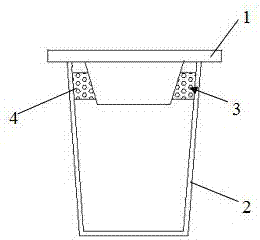

Image

Examples

Embodiment 13

[0078] The sealing piston 9 in Embodiment 13 is arranged inside the cavity and slides along the inner wall of the cavity 2, and the sealing pressure between the side wall of the sealing piston and the sealing surface of the inner wall of the cavity is greater than or equal to zero. When the sealing pressure is equal to zero, it indicates that the outer diameter of the sealing piston is smaller than the inner diameter of the cavity or is in a critical state of contact and non-contact. When the sealing pressure is greater than zero, that is, the outer diameter of the piston is greater than the inner diameter of the cavity and forms a Sliding seal, the sealing surface of the cavity is located at the contact surface between the inner wall of the cavity and the piston, and the sealing piston is made of elastic or flexible porous material. Porous material can be any one in polymer sponge, foamed plastics, rubber sponge, is preferably closed cell material, promptly forms a plurality o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap