Multifunctional intelligent hot melt glue gun and use method thereof

A hot melt glue gun, multi-functional technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of damage, long operation time, desktop pollution, etc., to achieve good bonding effect, continuous and stable glue delivery , The effect of adjustable glue feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solutions and beneficial effects of the present invention clearer, the implementation manners of the present invention will be further explained in detail below.

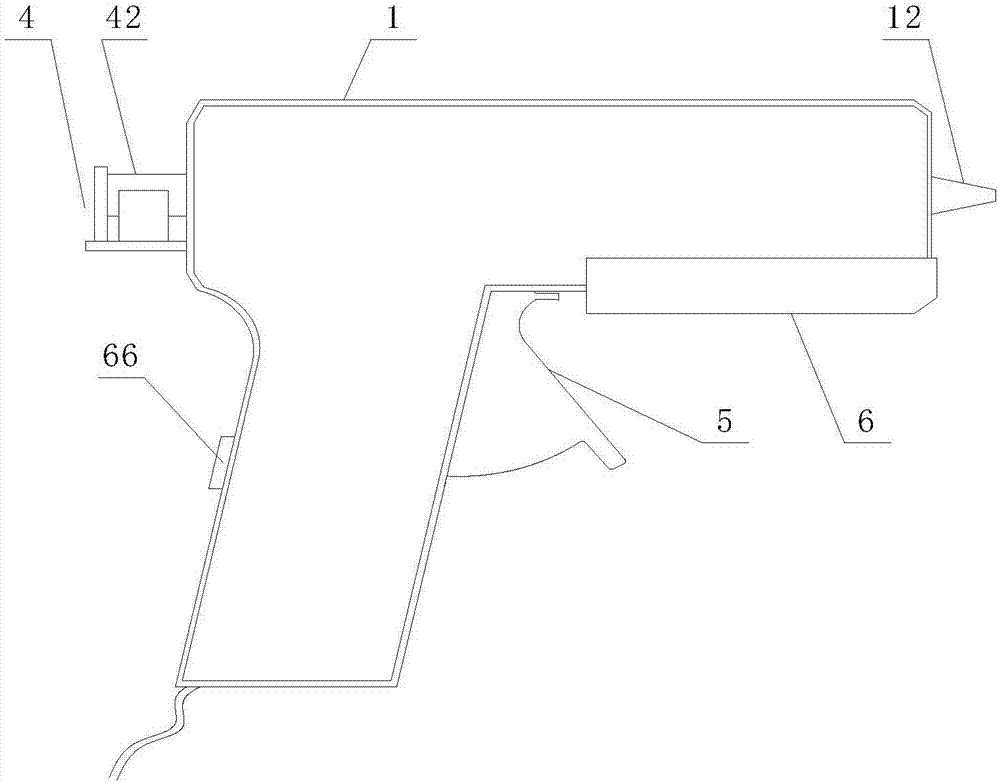

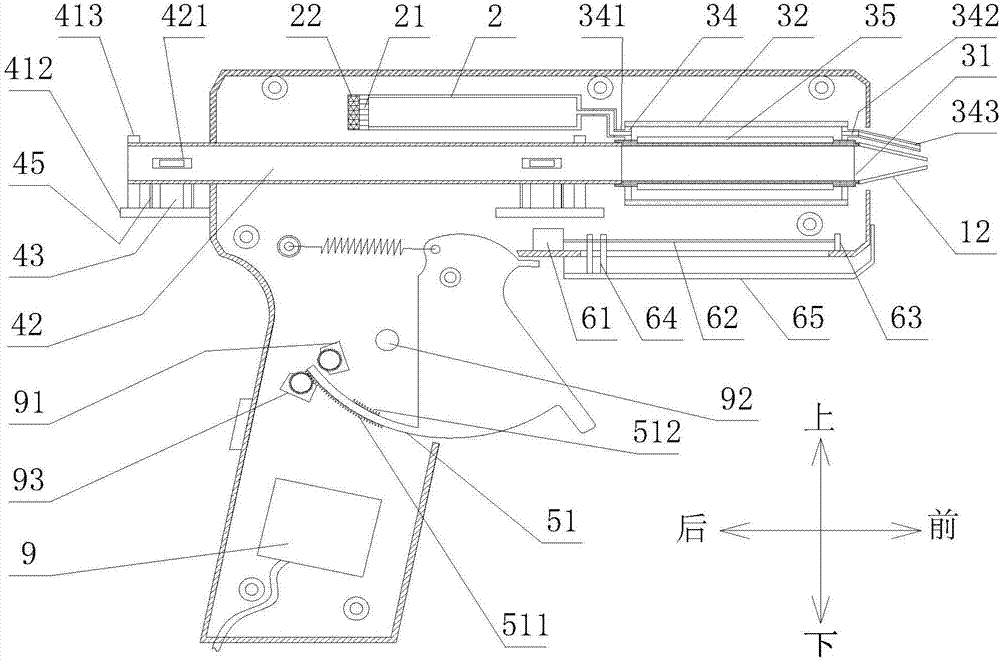

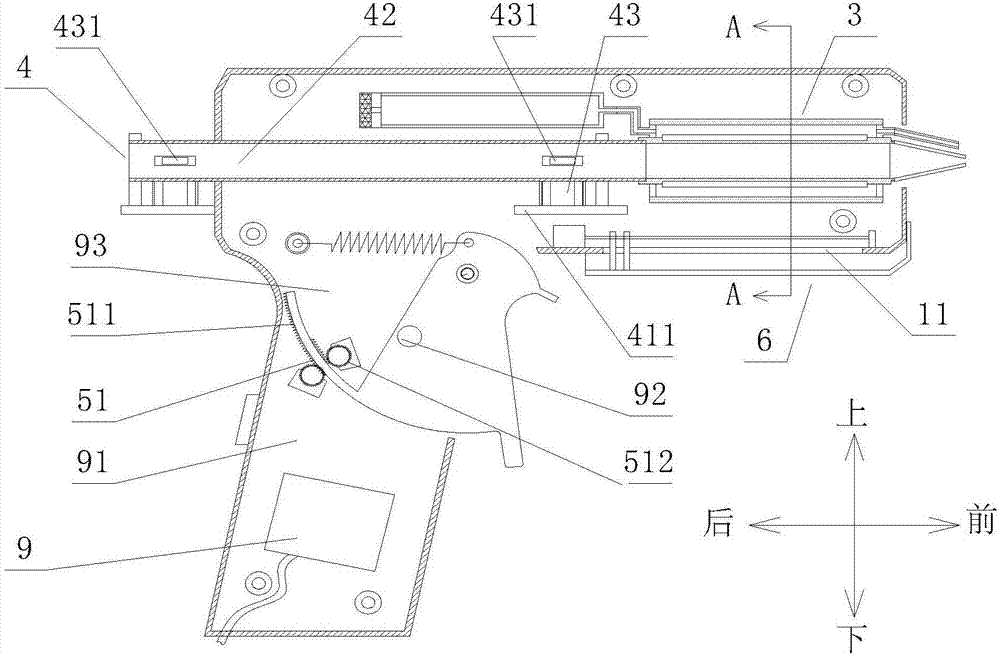

[0035] Such as figure 2 As shown, a multifunctional intelligent hot melt glue gun is similar to a traditional hot melt glue gun. A hot melt device 3, a propeller 4, and a trigger 5 are installed inside the housing 1 of the glue gun. The end is connected with a gun nozzle 12. In addition to improving the above-mentioned devices, the present invention also adds an air cavity 2 , a support and storage device 6 , a governor 91 , a limit electromagnetic lock 92 , a voltage regulator 93 and a controller 9 . In order to install the above-mentioned device inside and outside the glue gun housing 1, the glue gun housing 1 is manufactured by injection molding process, and provides a mounting slot for the above-mentioned device.

[0036] As we all know, the function of the hot-melt devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com