Stable welding device

A welding device and stable technology, applied in the field of stable welding devices, can solve problems such as electric shock for users, inconvenient welding work, and easy generation of arcs, etc., to achieve the effects of preventing electric shock accidents, reducing operating steps, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

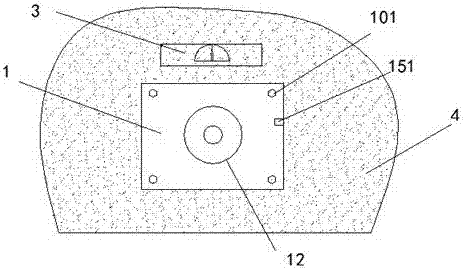

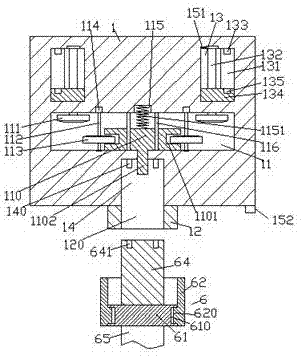

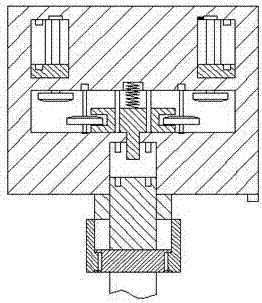

[0021] Such as Figure 1-Figure 6 As shown, a stable welding device of the present invention includes a power distribution base 1 and a fastening part 6, the power distribution base 1 is fixed on the wall 4 by bolts 101, and the power distribution base 1 above the The front end of the wall 4 is provided with a voltage converter 3, the voltage converter 3 is electrically connected to the power distribution base 1 through a line, and the voltage converter 3 is used to convert the output voltage of the power distribution base 1, thereby To meet the power connection requirements of electric welding machines with different powers, an external threaded part 12 is provided at the center of the front end of the power distribution base 1, and a threaded part 12 is provided inside the threaded part 12. The power distribution seat 1 on the side is provided with a fastening hole 14, and the inner wall of the rear side of the fastening hole 14 is provided with a second insert piece 140, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com