Annular workpiece jig with alarming function

A ring-shaped workpiece and jig technology, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as inclination and offset, lower processing accuracy, damage to workpieces or jigs, and achieve simple structure, Improve processing quality and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

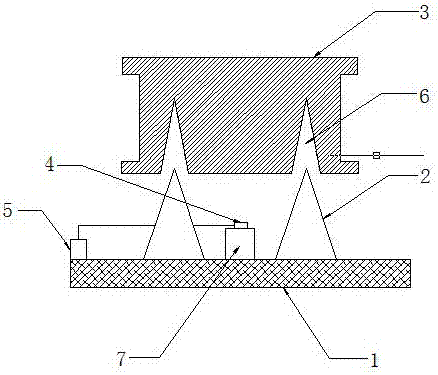

[0013] as attached figure 1 As shown, a ring-shaped workpiece fixture with an alarm function includes a base 1, a conical extrusion head 2, an elastic collet 3, a pressure sensor 4, and an alarm 5. Two conical clamps are fixedly installed on the base 1. Extrusion head 2, elastic collet 3 is set above the conical extrusion head 2, tapered hole 6 is set at the lower part of the conical extrusion head 3, and the conical extrusion head A raised platform 7 is set between 2, a pressure sensor 4 is installed on the platform 7, and the pressure sensor 4 is connected to the alarm 5.

[0014] The apex angle of the tapered hole 6 is smaller than the apex angle of the conical extrusion head 2 .

[0015] The height of the platform 7 is 1 / 3 of the height of the conical extrusion head 2 .

[0016] Described alarm 5 is sound and light alarm.

[0017] When the present invention is in use: a ring-shaped workpiece fixture with an alarm function, including a base, a tapered extrusion head, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com